Reverse demulsifier and preparation method thereof

An inverse demulsifier and reaction technology, applied in the field of petroleum industry, can solve the problems of increasing the mechanical strength and negative charge of the oil-water interface film, and the difficulty of separating oil and water from chemical flooding production fluid, achieving good demulsification effect, low equipment requirements, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, the synthesis of inverse demulsifier A

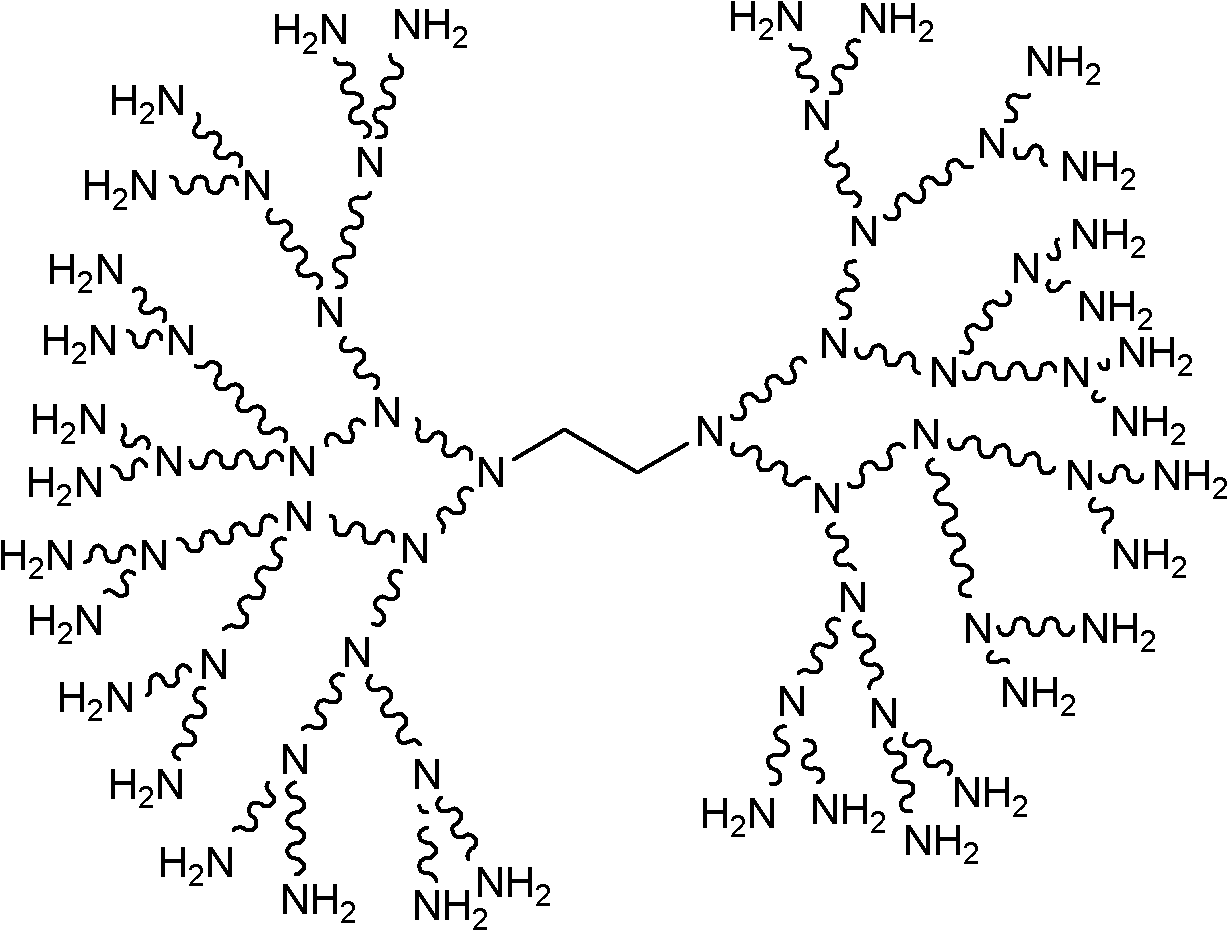

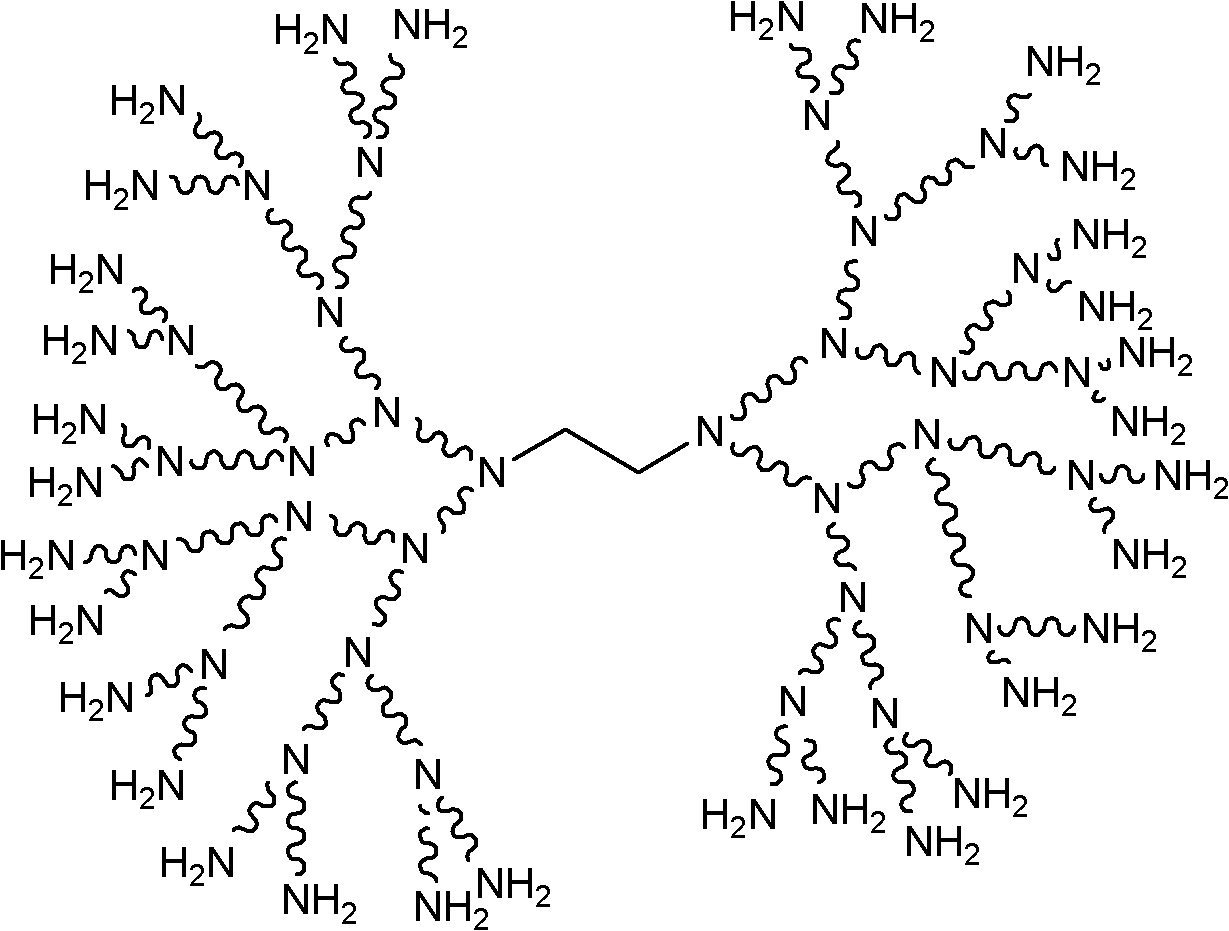

[0023] (1) Synthesis of cationic polyamide-amine

[0024] At room temperature, slowly drop epichlorohydrin into the 3.0-generation polyamide-amine aqueous solution represented by formula (I), raise the temperature to 45°C, react for 24 hours, and use N,N-dimethylformamide as a solvent to precipitate the product cation The mass of polyamidoamine CPA01; 3.0 generation polyamidoamine and epichlorohydrin is 12 grams and 10 grams respectively.

[0025] (2) Synthesis of polyepichlorohydrin quaternary ammonium salt

[0026] At 0°C, slowly drop epichlorohydrin into a three-necked flask filled with ethylene glycol, tin tetrachloride and trifluoroacetic acid, control the reaction temperature at 0°C, after 5 hours of reaction, raise the temperature to 45°C, and add to the reaction Trimethylamine aqueous solution was added dropwise to the system, and after 24 hours of reaction, the solvent was distilled off under reduced pres...

Embodiment 2

[0031] Embodiment 2, the synthesis of inverse demulsifier B

[0032] (1) Synthesis of cationic polyamide-amine

[0033] At room temperature, slowly drop epichlorohydrin into the 3.0-generation polyamide-amine aqueous solution represented by formula (I), raise the temperature to 50°C, react for 24 hours, and use N,N-dimethylformamide as a solvent to precipitate the product cation The mass of polyamidoamine CPA02; 3.0 generation polyamidoamine and epichlorohydrin is 50 grams and 3 grams respectively.

[0034] (2) Synthesis of polyepichlorohydrin quaternary ammonium salt

[0035] At 0°C, slowly drop epichlorohydrin into a three-necked flask filled with ethylene glycol, tin tetrachloride and trifluoroacetic acid, control the reaction temperature at 10°C, after 5 hours of reaction, raise the temperature to 50°C, and add to the reaction Trimethylamine aqueous solution was added dropwise to the system, and after reacting for 24 hours, the solvent was distilled off under reduced pre...

Embodiment 3

[0040] Embodiment 3, the synthesis of inverse demulsifier C

[0041] (1) Synthesis of cationic polyamide-amine

[0042] At room temperature, slowly drop epichlorohydrin into the 3.0-generation polyamide-amine aqueous solution represented by formula (I), raise the temperature to 45°C, react for 12 hours, and use N,N-dimethylformamide as a solvent to precipitate the product cation The mass of polyamidoamine CPA03; 3.0 generation polyamidoamine and epichlorohydrin is 100 grams and 1 gram respectively.

[0043] (2) Synthesis of polyepichlorohydrin quaternary ammonium salt

[0044]At 0°C, slowly drop epichlorohydrin into a three-necked flask filled with 1,4-butanediol and tin tetrachloride, control the reaction temperature at 5°C, after 1 hour of reaction, raise the temperature to 45°C, and add to the reaction system Triethylamine aqueous solution was added dropwise, and after reacting for 12 hours, the solvent was distilled off under reduced pressure at 50°C to obtain polyepichl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com