High-temperature-resistance compound medium isolating method of aluminum base film temperature sensor

A thin-film temperature and composite medium technology, which is applied in the field of high-temperature-resistant composite medium isolation of aluminum-based thin-film temperature sensors, can solve the problems of sensitive line interruption, line erosion, and etching solution accumulation, etc., and achieve simple manufacturing process and substrate integration. High force, good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

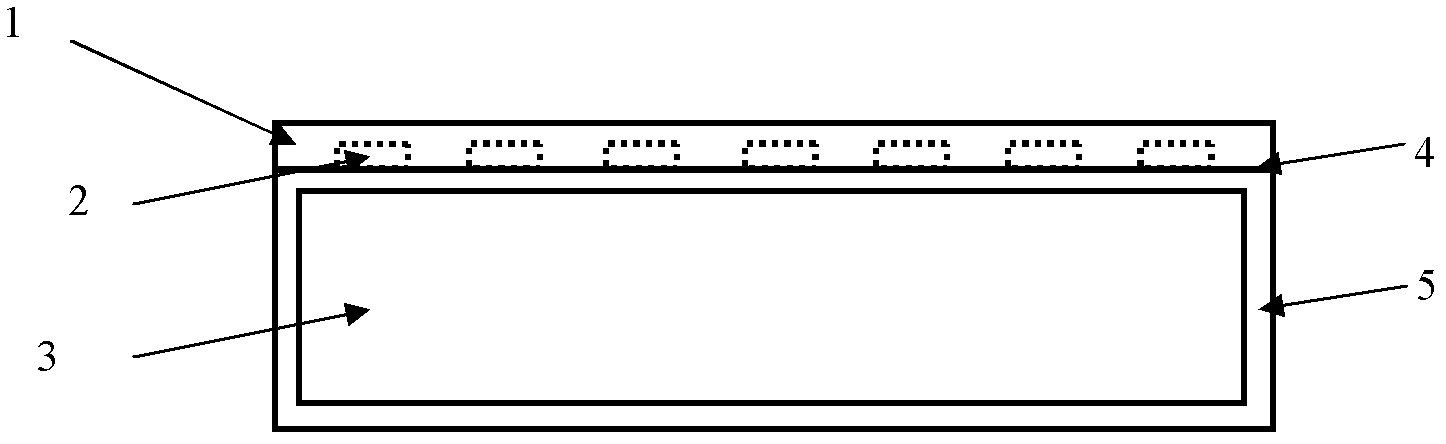

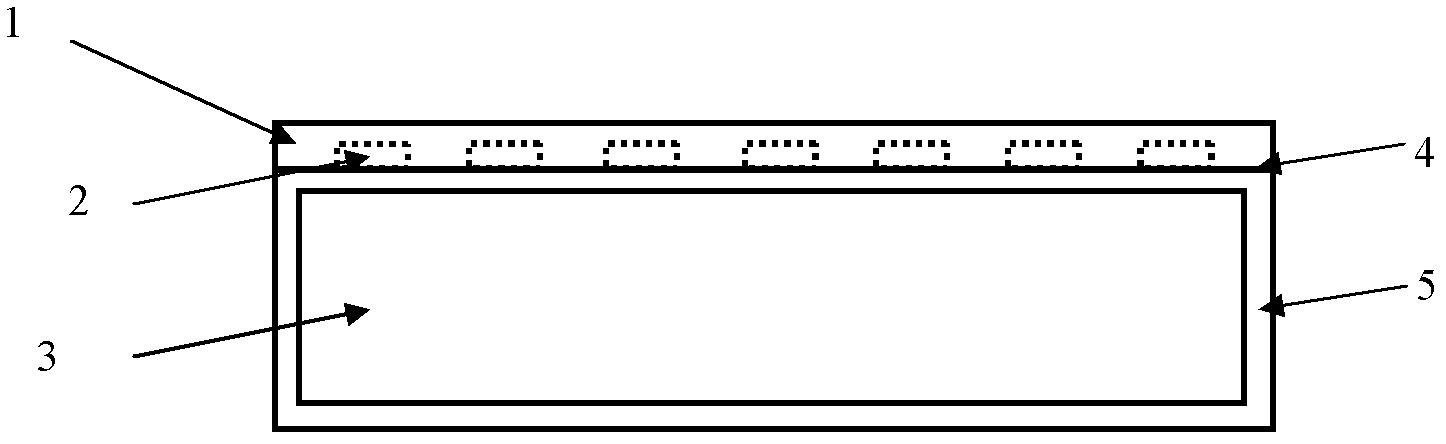

[0018] Technical means of the present invention mainly comprises:

[0019] Select industrial pure aluminum as the raw material, and process the sample size according to the requirements.

[0020] The aforementioned samples were subjected to pretreatment processes such as sandpaper grinding and electrochemical polishing.

[0021] The aforementioned pretreated samples were placed in an aqueous electrolyte solution doped with rare earth element additives for insulating anodic oxidation.

[0022] The aforementioned anodized samples were sealed at high temperature for 30 minutes in a sealing solution containing rare earth elements, and then dried naturally.

[0023] The aforementioned surface of the oxide film after hole sealing is subject to mechanical polishing.

[0024] The oxide film surface of the aforementioned loose layer is removed, and a layer of Al is prepared by electron beam evaporation. 2 o 3 membrane.

[0025] The following examples describe the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com