Swill-cooked dirty oil detecting system and detecting method

A detection system and technology for waste oil, which are used in measurement devices, color/spectral property measurement, material analysis by optical means, etc., can solve problems such as destructive detection, inability to use flower and color vegetable oil detection, and prone to false positives. Accurate test results, simple process and wide range of oil products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

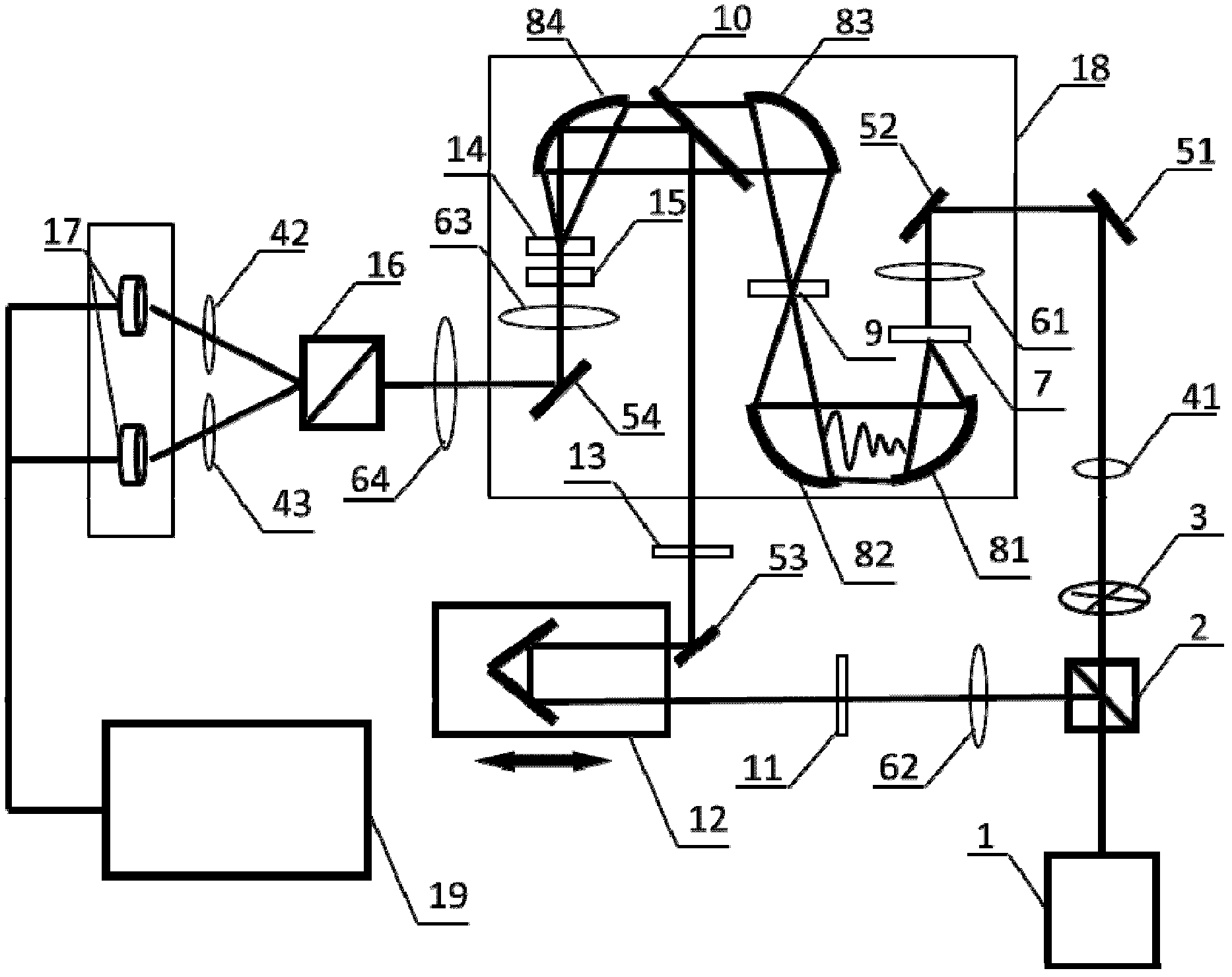

[0031] A waste oil detection system, such as figure 1 , figure 2 shown. Including: femtosecond laser 1, transflective beam splitter 2, optical chopper 3, reflector, focusing lens, gallium arsenide photoconductive antenna 7, parabolic mirror, sample box 9, high resistance silicon reflector 10, An optical path delay device 12 , an electro-optic crystal 14 , a Walstone prism 16 , a photodetector 17 , and a lock-in amplifier 19 .

[0032]A) At the exit position of the femtosecond laser 1, a semi-reflective and semi-transparent beam splitter 2 is arranged to divide the pulsed laser light into a pumping light path and a detection light path; the optical chopper 3, the first attenuation plate 41, The first reflector 51, the second reflector 52 and the first focusing lens 61 are located on the pumping light path between the semi-reflective beam splitter 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com