Method for simultaneously determining harmful elements in iron ore

A technology for harmful elements and iron ore, applied in the field of quantitative analysis in analytical chemistry, it can solve the problems of complicated operation and processing steps, low sensitivity and poor reproducibility, and achieve the effect of reducing solvent consumption, high sensitivity and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

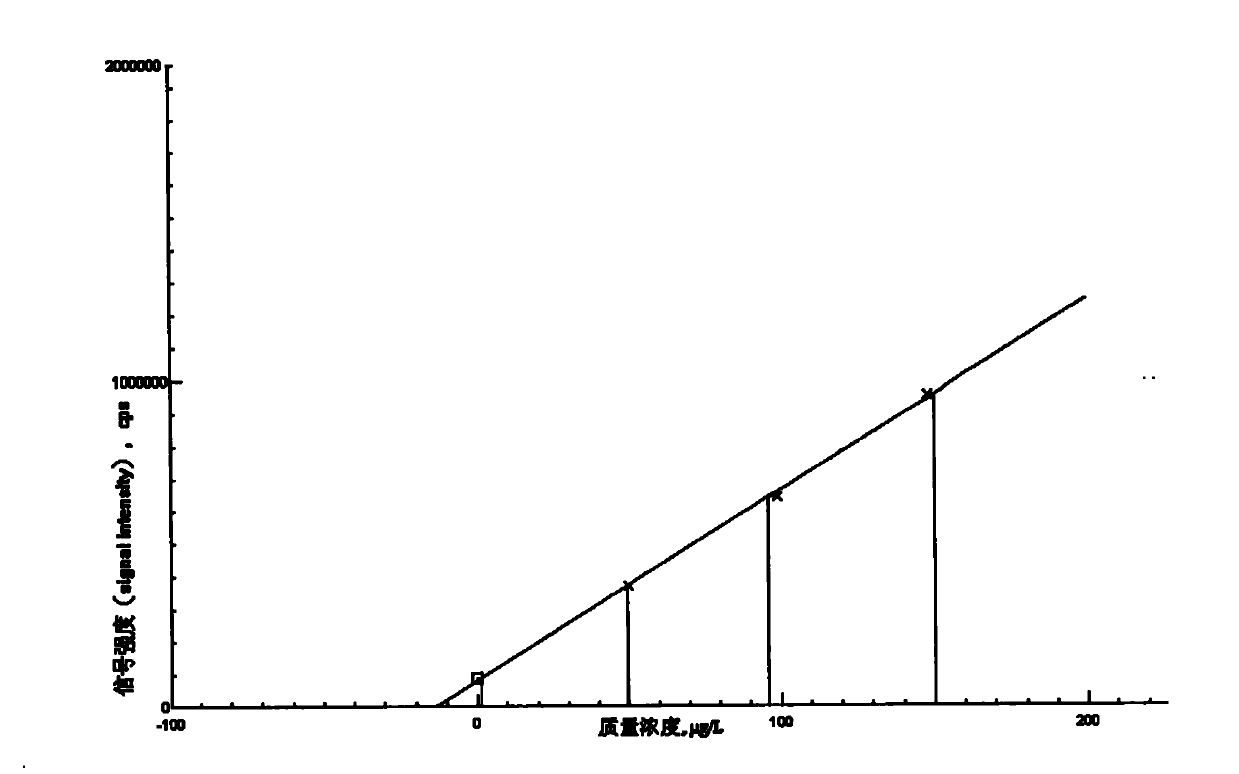

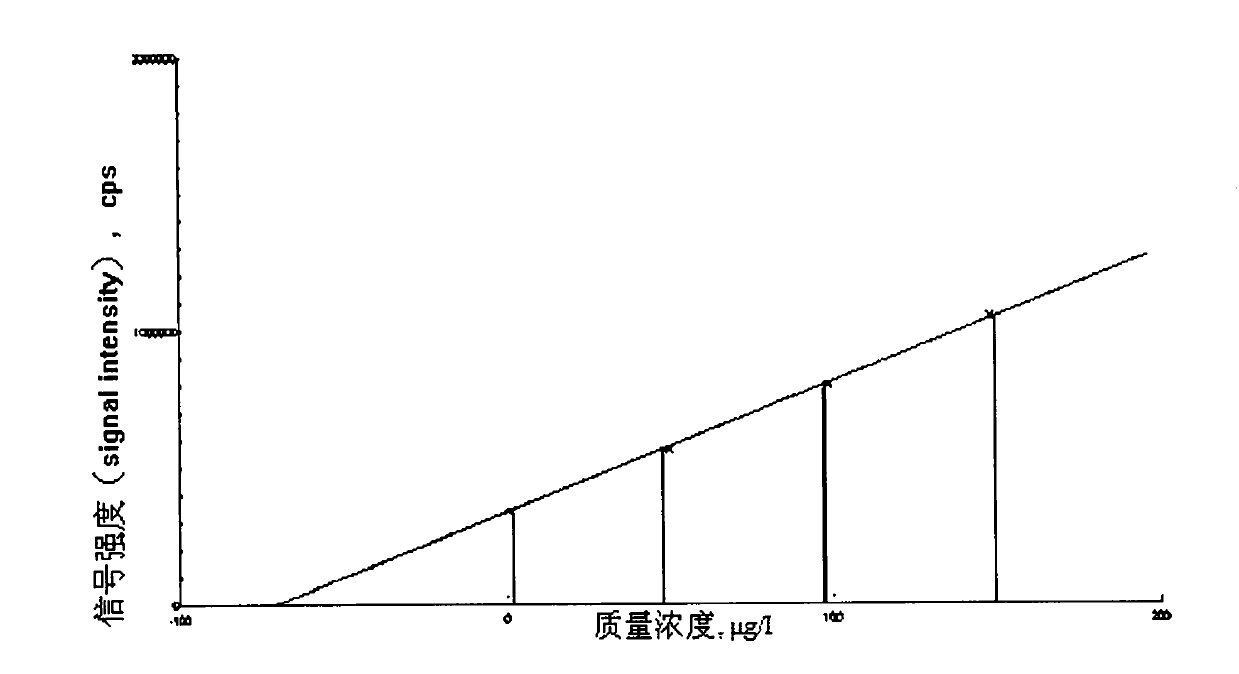

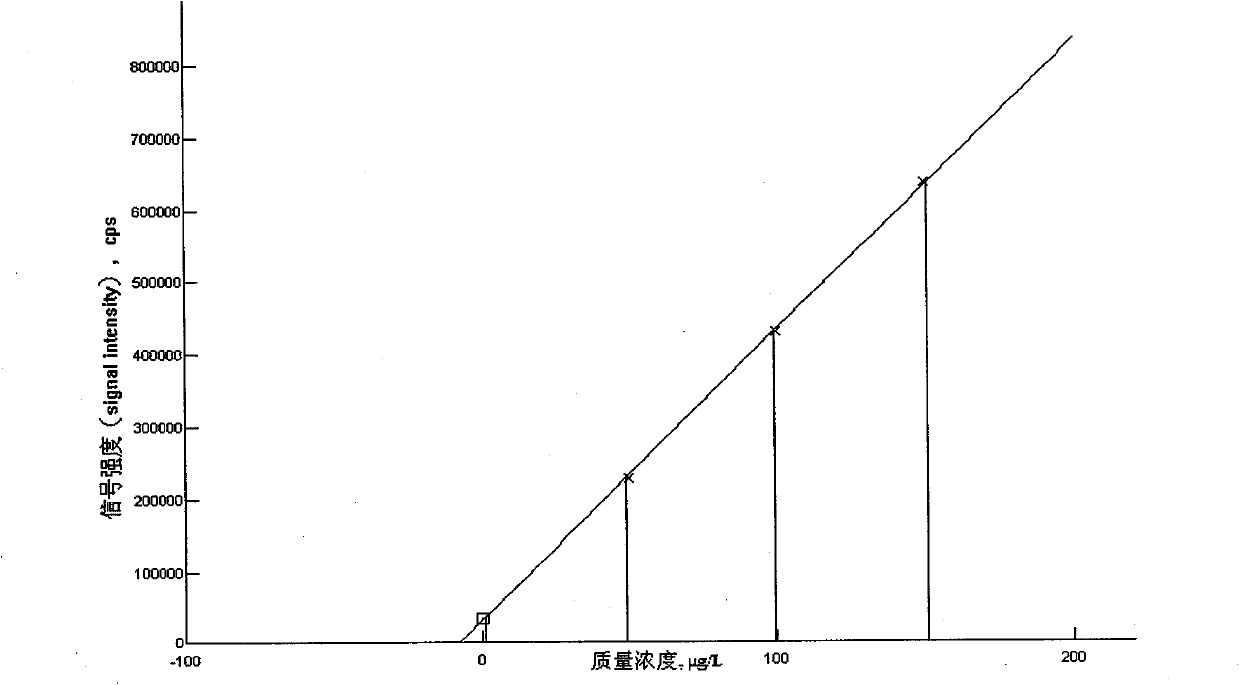

Image

Examples

Embodiment 1

[0026] Determination of Na, K, Pb, Zn element content in iron ore national standard sample GSBH 30002-97:

[0027] 1. Samples processed by microwave digestion: Accurately weigh 0.1000g of iron ore sample, put it in a microwave digestion tank cleaned by acid boiling, add 10mL of hydrochloric acid (1:1) and 3mL of nitric acid in sequence after the second sub-boiling distillation, Hydrofluoric acid 1mL, assemble the digestion tank, and prepare a blank sample at the same time, place the microwave digestion tank in the microwave digestion instrument; turn on the microwave digestion instrument, set the program as: power 1000W, temperature 200°C, and the heating program is 3min to 150°C, hold the temperature for 3 minutes, then raise the temperature to 200°C for 5 minutes, and start to cool down after holding the temperature for 10 minutes. After the digestion is complete, take out the digestion tank when the temperature drops to room temperature, transfer the test solution to a 100m...

Embodiment 2

[0045] Embodiment 2: the mensuration of actual iron ore sample Na, K, Pb, Zn element content:

[0046] 1. Accurately weigh 0.1000g of four iron ore samples, place them in a microwave digestion tank cleaned by acid boiling, and add 10mL of hydrochloric acid (1:1) after the second sub-boiling distillation, 3mL of nitric acid, hydrofluoric acid 1mL, assemble the digestion tank, and prepare a blank sample at the same time, place the microwave digestion tank in the microwave digestion instrument; turn on the microwave digestion instrument, set the program as: power 1000W, temperature 200°C, and the heating program is 3min to 150°C, Keep the temperature constant for 3 minutes, then raise the temperature to 200°C for 5 minutes, and start to cool down after 10 minutes of constant temperature. After the digestion is complete, take out the digestion tank when the temperature drops to room temperature, transfer the test solution to a 100mL plastic volumetric flask, and constant volume. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com