Manufacturing method of passivated InAs/GaSb secondary category superlattice infrared detector

A technology of infrared detector and manufacturing method, applied in semiconductor device, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as device performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

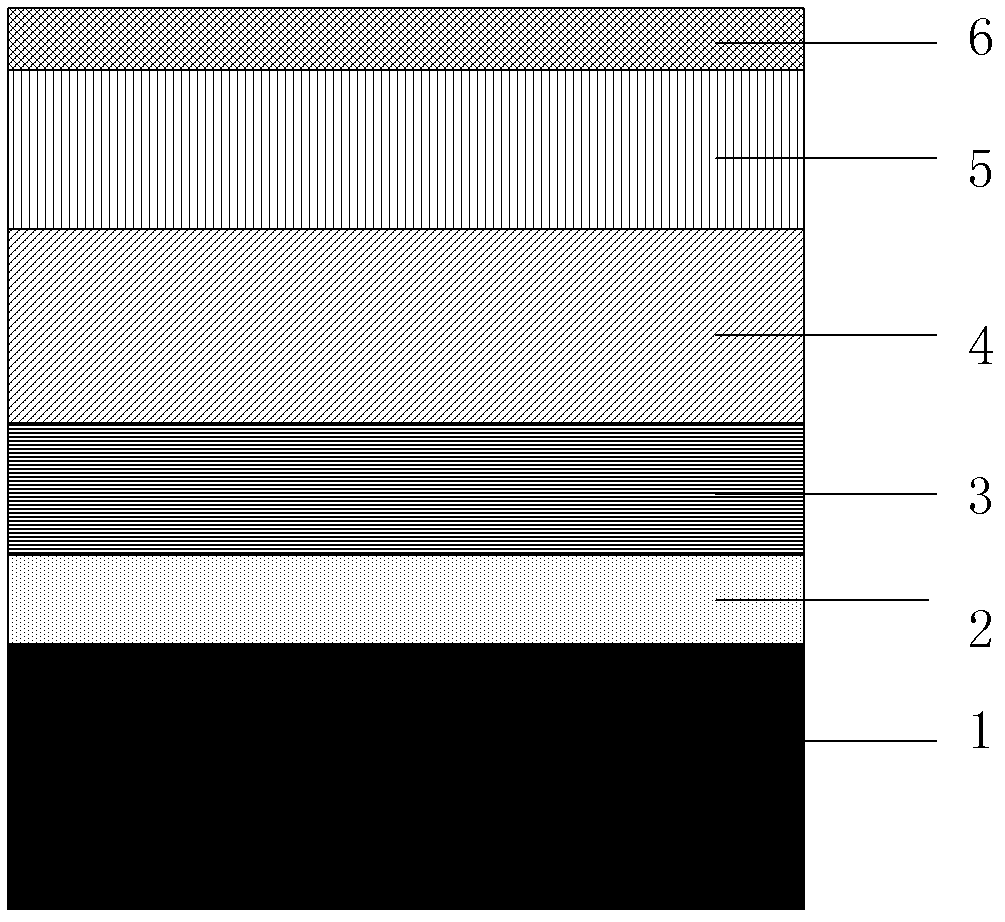

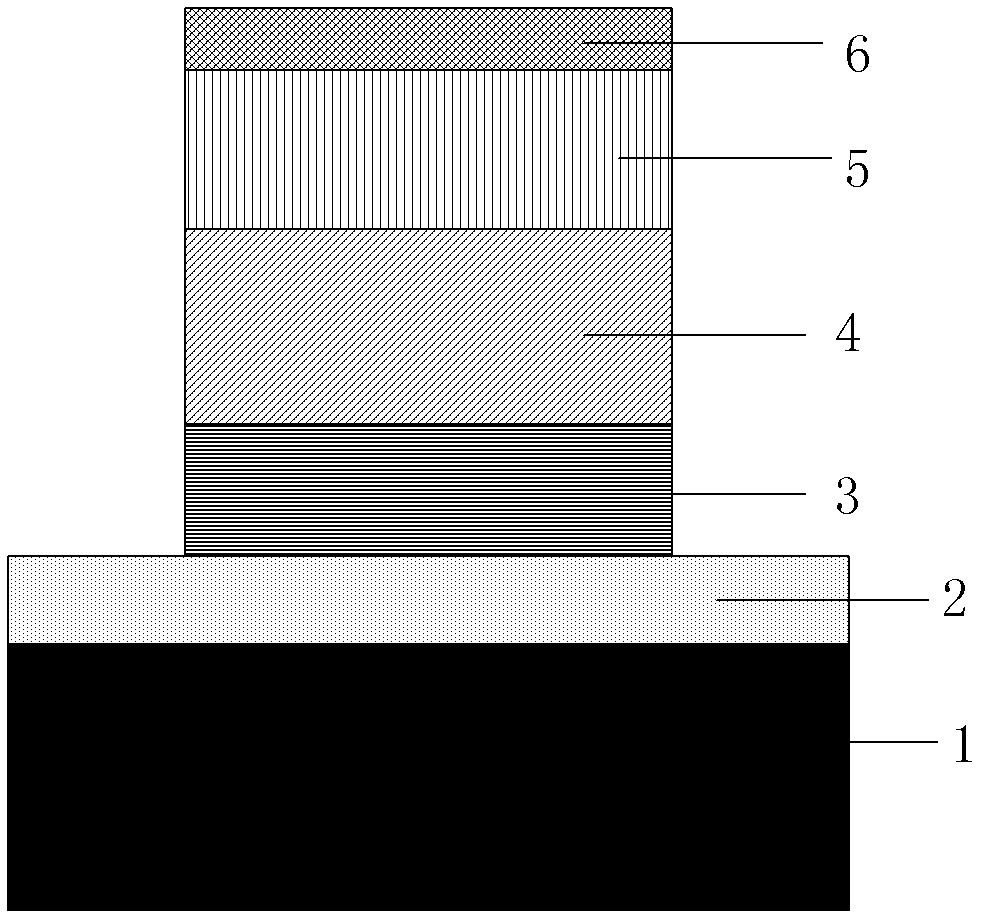

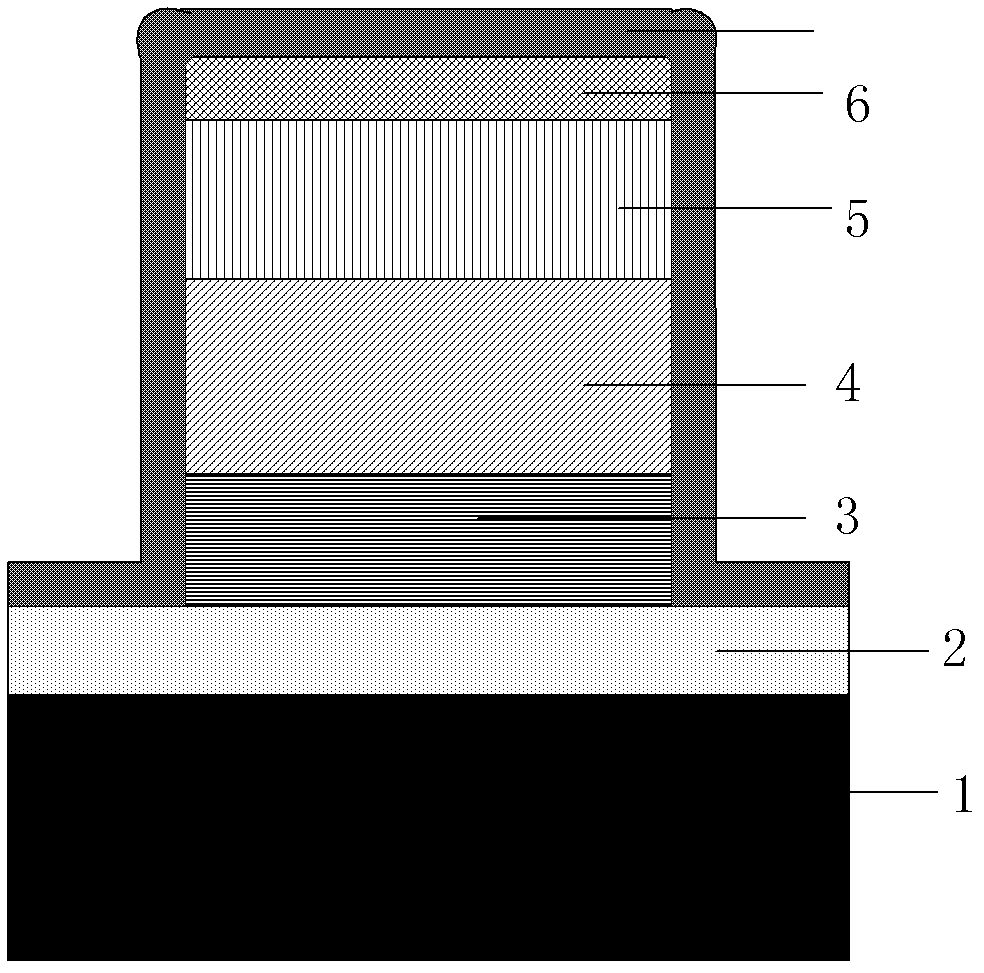

[0028] see figure 1 As shown, the present invention provides a kind of passivation InAs / GaSb class II superlattice infrared detector manufacturing method, comprises the following steps:

[0029] Step 1: Grow a P-type GaSb buffer layer 2, a P-type InAs / GaSb type II superlattice layer 3, and an intrinsic InAs / GaSb II layer sequentially on a GaSb substrate 1 by metal chemical organic vapor deposition or molecular beam epitaxy. A superlattice-like light absorption layer 4, an N-type InAs / GaSb second-type superlattice layer 5 and an N-type InAs ohmic contact layer 6 form an epitaxial wafer, and its structure is as follows figure 1 shown;

[0030] Step 2: Boil the epitaxial wafer with trichlorethylene, acetone and methanol at 50°C for 5 minutes under ultrasonic waves, then use isopropanol to dehydrate, and use N 2 Blow dry and dry in an oven;

[0031] Step 3: use the designed photolithography plate to perform the first photolithography on the epitaxial wafer, and then use citric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com