Novel nickel-hydrogen battery diaphragm

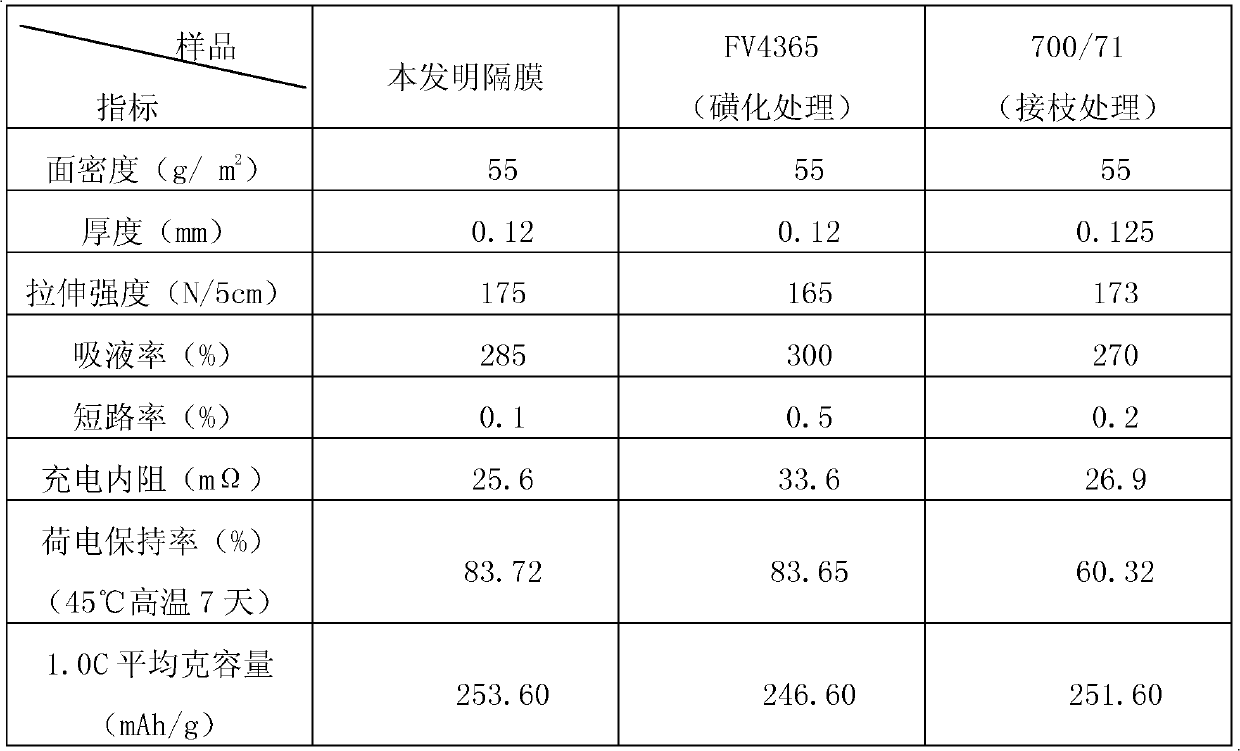

A nickel-metal hydride battery and separator technology, applied in the field of separators for batteries, can solve the problems of unsuitability for manufacturing nickel-hydrogen power batteries, easy carbonization of ultra-fine fibers, low charge retention rate, etc., and achieves excellent charge retention capability, The effect of homogenizing pore size and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

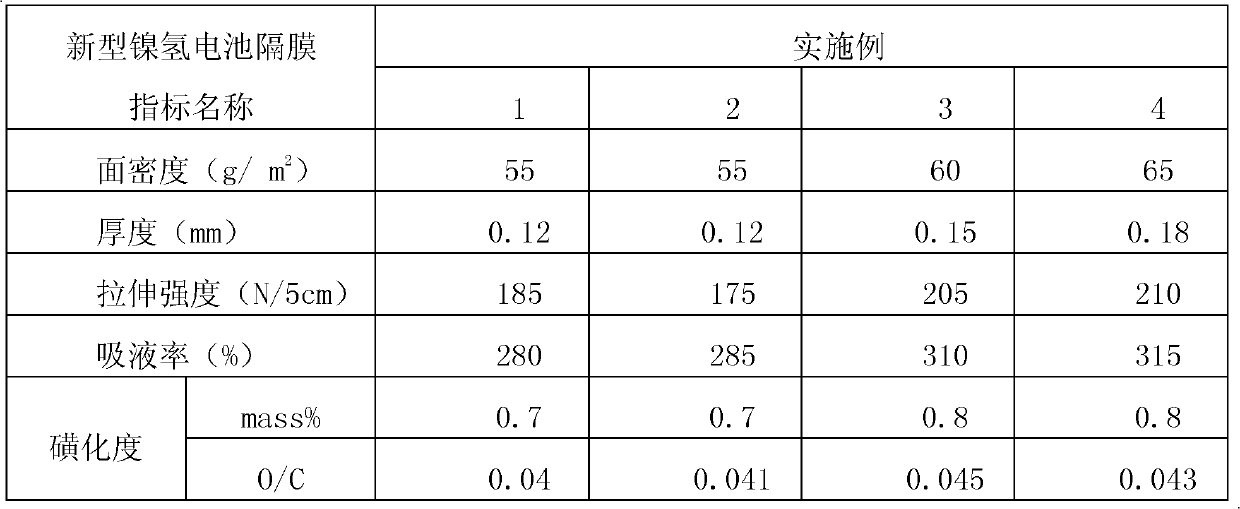

Embodiment 1

[0021] The fiber materials are compounded according to the weight ratio, that is, polyolefin sheath-core fiber, fiber fineness 0.8dtex, length 38mm, content 70%; polypropylene fiber, fineness 1.1dtex, length 38mm, content 25%; polypropylene fiber, fineness 0.3 dtex, length 38mm, content 5%, the above fibers are formed by dry carding process, reinforced by spunlace, dried in hot air at 120 ℃, adjusted to a certain thickness with a rolling mill, and made into diaphragm base cloth, diaphragm base cloth Surface density is 50g / m 2 .

[0022] The diaphragm base cloth is transported to the sulfonation reactor, and sulfonated with 95% concentration of gaseous sulfur trioxide, and the sulfonated base cloth is transported to the alkali washing tank for neutralization reaction, and the concentration of potassium hydroxide is 2%. The alkali cleaning speed is controlled at 15 m / min, and then rinsed with deionized water, rolled, and dried at a temperature of 100°C to obtain a diaphragm bas...

Embodiment 2

[0026] Polyolefin sheath-core fibers are used to make diaphragm base fabrics, the fiber fineness is 0.8dtex, and the fiber length is 2mm to 15mm. The thickness of the base fabric is adjusted through beating, sizing, molding, spunlace, and drying using wet papermaking technology. , made into a diaphragm base fabric with a surface density of 50g / m 2 , and then processed by the sulfonation and chemical grafting treatment method and order of Example 1, to obtain a surface density of 55g / m 2 , a new type of Ni-MH battery separator with a thickness of 0.12mm, a sulfonation degree of 0.7%, and an O / C of 0.041.

Embodiment 3

[0028] The diaphragm base fabric is made of polypropylene fiber, wherein the polypropylene fiber with a fineness of 1.1dtex and a length of 38mm accounts for 95%; the polypropylene fiber with a fineness of 0.3dtex and a length of 38mm accounts for 5%, and the above fibers are carded by dry method Process molding, spunlace reinforcement, drying in hot air at 130°C, adjusting to a certain thickness with a rolling mill, and making a diaphragm base cloth, the surface density of the diaphragm base cloth is 55g / m 2 .

[0029] Put the diaphragm base into the grafting modification solution, the weight concentration of the monomeric acrylic acid is 3%, add the initiator, carry out the sufficient polymerization and grafting reaction at 95°C, wash with deionized water, and dry to obtain For the diaphragm base cloth with a graft ratio of 3%, the thickness of the base cloth is adjusted once more with a rolling mill.

[0030] Transfer the adjusted thickness of the grafted diaphragm base cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com