Multi-wavelength semiconductor laser based on annular resonant cavity

A ring resonator and laser technology, which is applied in semiconductor laser devices, optical waveguide semiconductor structures, laser devices, etc., can solve the problems of difficult large-scale integration of devices, complex device packaging, and complex material growth, etc., to reduce the difficulty of growth , Simple and compact structure, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

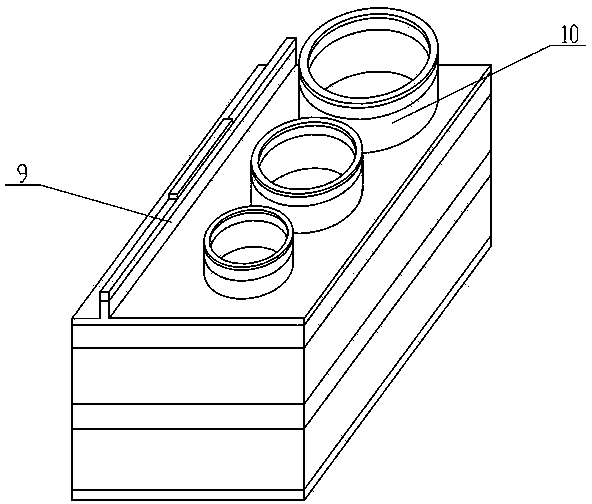

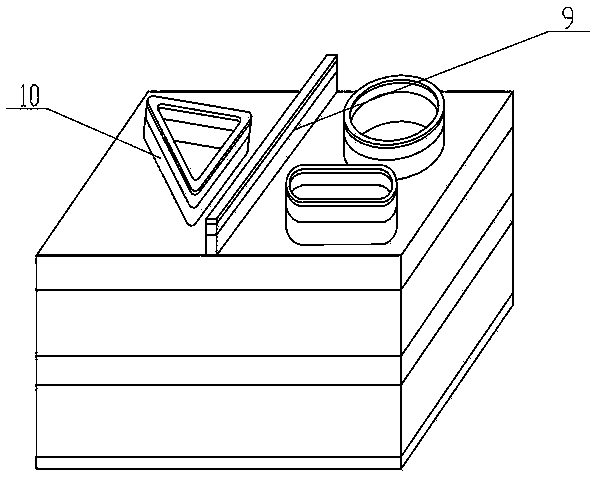

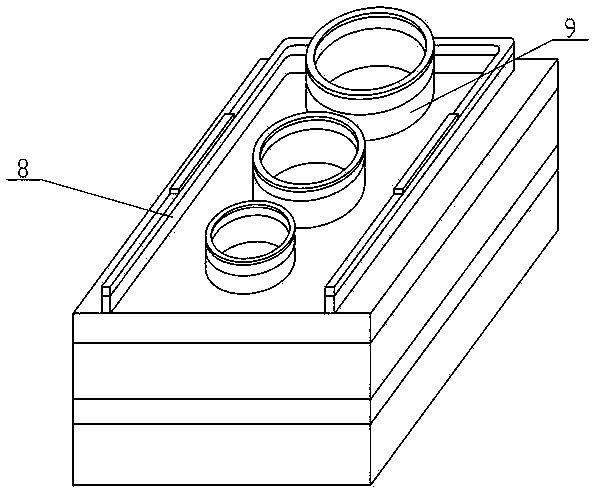

Image

Examples

Embodiment 1

[0024] Example 1 is made of III-V compounds, and GaAs / Al is selected according to the lasing wavelength x Ga 1-x As, InP / In 1-x Ga x As y P 1-y or InP / Al x In 1-x-y Ga y As quantum well material is used as the active layer (that is, the active region) 4, where the values of x and y can be designed according to the corresponding wavelength. Taking the layer structure of a laser with a wavelength of 1550nm as an example, the layer structure is grown sequentially from bottom to top on an InP substrate by using molecular beam epitaxy (MBE) or metal organic chemical vapor deposition (MOCVD) and other thin film epitaxy equipment: Doped N-type InP substrate layer 7 (i.e. lower ohmic contact layer), N-type InP buffer layer 6, 1 μm thick N-type InP lower cladding layer 5, 6 periods of AlxIn 1-x-y Ga y As multi-quantum well active layer 4, 1.6 μm thick P-type InP upper cladding layer 3, 0.3 μm thick P-type heavily doped In 0.53 Ga 0.47 As ohmic contact layer 2. Among them,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com