Method for improving antibacterial property of tetrapod-like zinc oxide whisker

A four-needle zinc oxide and whisker technology, which is applied in the field of preparation of four-needle zinc oxide whisker composite antibacterial materials, can solve the problem of complex silver ion doping process, few active centers of needles, and poor tip nano-effect and other problems, to achieve broad application prospects, improve the sterilization ability, and the effect of strong sterilization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for improving the antibacterial properties of tetraacicular zinc oxide whiskers, the steps are:

[0025] A, powdery tetraacicular zinc oxide whiskers are added to potassium sodium tartrate aqueous solution to form a paste, stirred for 30 minutes, the mol ratio of described potassium sodium tartrate and tetraacicular zinc oxide whiskers is 1: 100; Slowly add an aqueous solution of cupric chloride equimolar to potassium sodium tartrate under stirring (that is, the molar mass of cupric chloride contained in the aqueous solution is equal to potassium sodium tartrate); after that, continue to stir for 60 minutes; finally, filter , washing, and drying to obtain tetraacicular zinc oxide whisker composite powder with nano-copper tartrate deposited on the surface in situ;

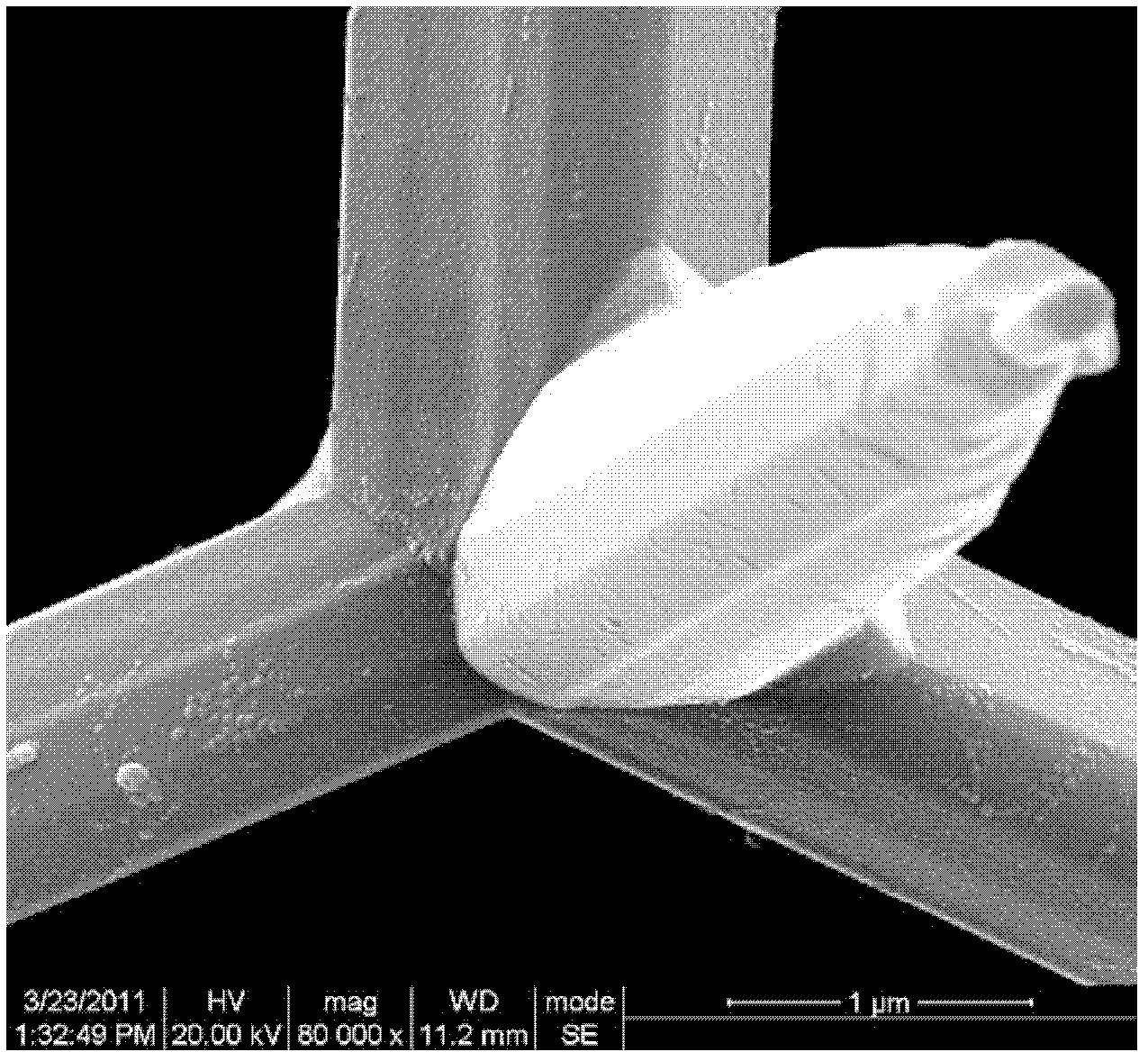

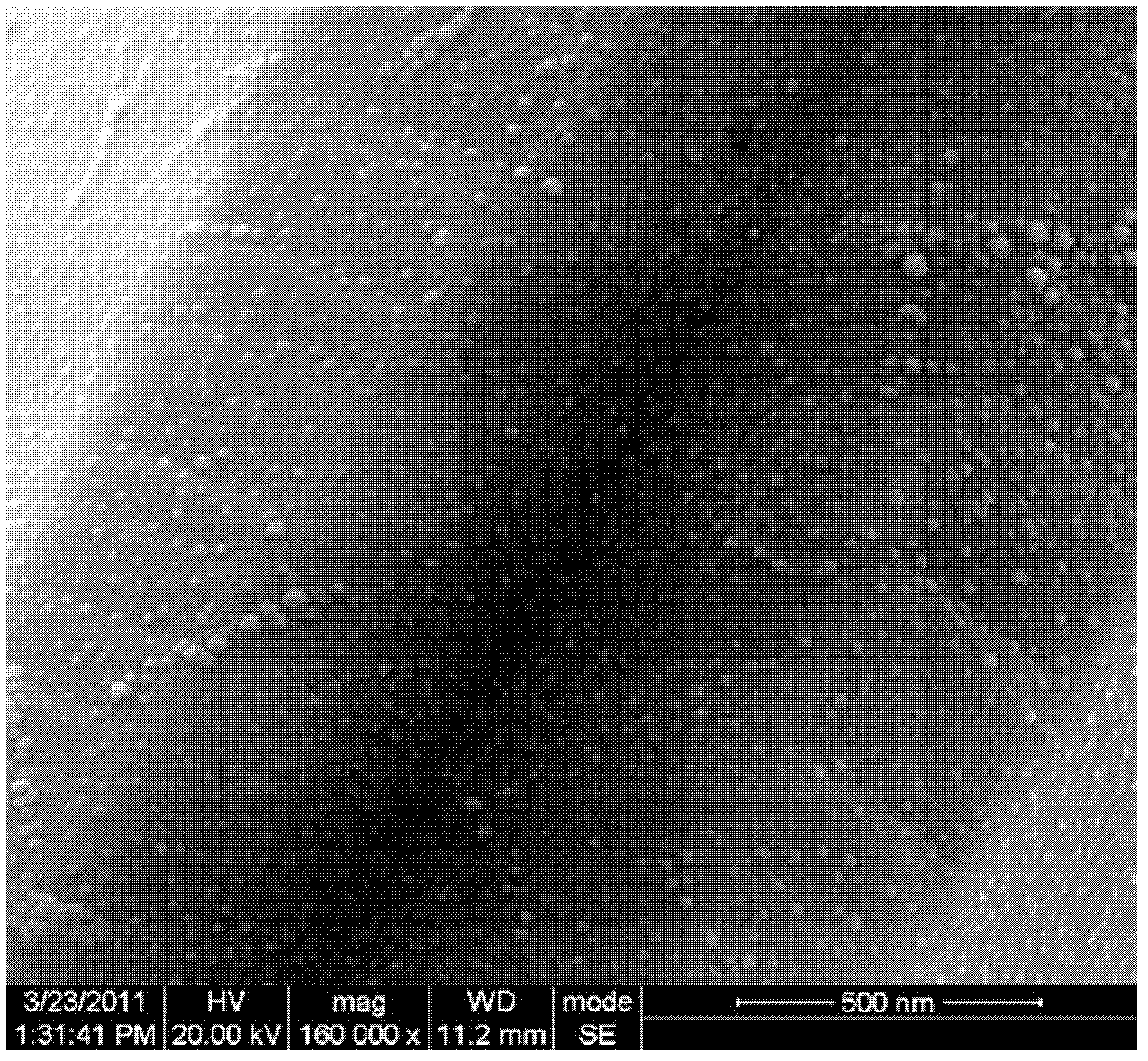

[0026] B. Heat the composite powder obtained in step A to 270° C. for 60 minutes in a hydrogen atmosphere, and cool to room temperature to obtain tetrapod-shaped zinc oxide whisker powder with nano-c...

Embodiment 2

[0030] A method for improving the antibacterial properties of tetraacicular zinc oxide whiskers, the steps are:

[0031] A, powdery tetraacicular zinc oxide whiskers are added to potassium sodium tartrate aqueous solution to form a paste, stirred for 30 minutes, the mol ratio of described potassium sodium tartrate and tetraacicular zinc oxide whiskers is 0.8: 100; Slowly add an aqueous solution of copper chloride in an equimolar amount to potassium sodium tartrate under stirring; then, continue to stir for 60 minutes; finally, after filtering, washing, and drying, a four-needle-shaped copper tartrate nano-copper tartrate is deposited in situ on the surface. Zinc oxide whisker complex powder;

[0032] B. Heat the composite powder obtained in step A to 270° C. for 40 minutes in a hydrogen atmosphere, and cool to room temperature to obtain tetraacicular zinc oxide whisker powder with nano-copper deposited on the surface.

Embodiment 3

[0034] A method for improving the antibacterial properties of tetraacicular zinc oxide whiskers, the steps are:

[0035] A, the powdery tetraacicular zinc oxide whiskers are added to the aqueous solution of sodium potassium tartrate to form a suspension, stirred for 20 minutes, and the mol ratio of the described potassium sodium tartrate and tetraacicular zinc oxide whiskers is 0.6: 100; Slowly add the aqueous solution of cupric chloride equimolar with potassium sodium tartrate under stirring state again; Afterwards, continue to stir 50 minutes; Finally, through filtering, washing, drying, obtain the tetrachloride that the in situ deposition of surface has nano-copper tartrate Acicular zinc oxide whisker complex powder;

[0036] B. Heat the composite powder obtained in step A to 270° C. for 30 minutes in a hydrogen atmosphere, and cool to room temperature to obtain tetraacicular zinc oxide whisker powder with nano-copper deposited on the surface.

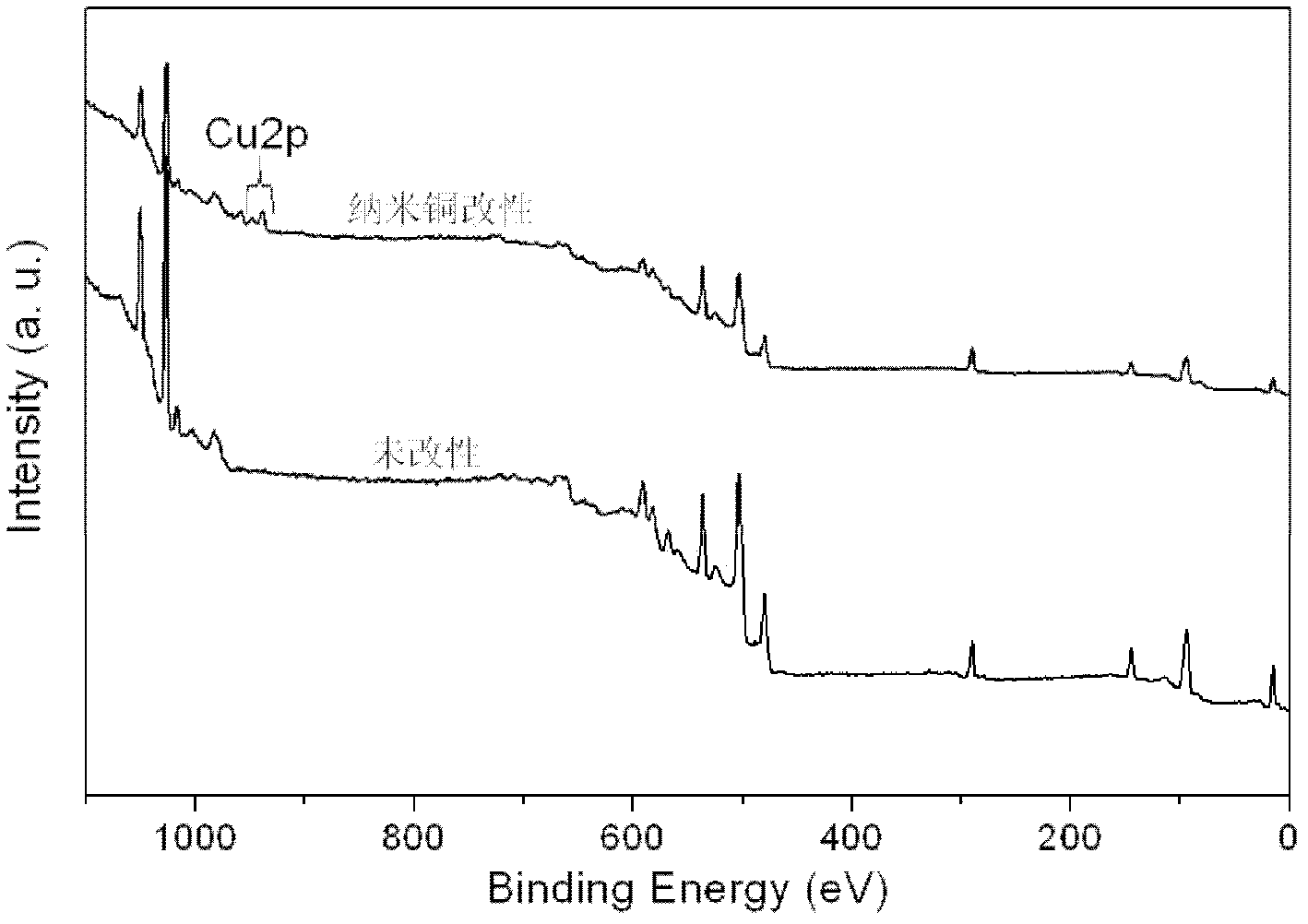

[0037] Figure 4 It is a g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com