Nano magnesium oxide doped biomass graded porous carbon/sulfur anode and preparation method thereof, and application of nano magnesium oxide doped biomass graded porous carbon/sulfur anode

A nano-magnesium oxide, graded porous technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of fast capacity decay and low utilization rate of active materials, achieve good dispersion, improve Electrochemical properties, effects for immobilization and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

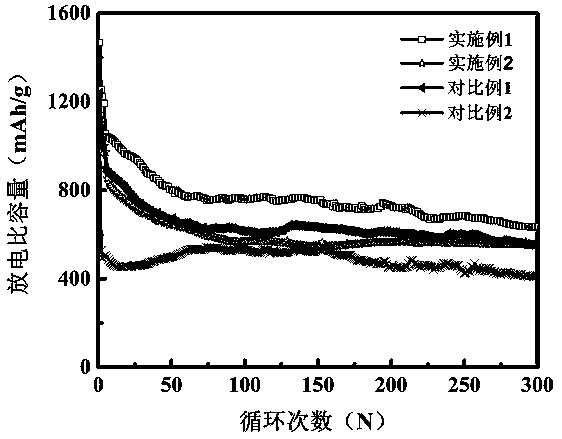

Embodiment 1

[0037] (1) Crab shells are used as raw materials, washed, dried, and pulverized. In the nitrogen atmosphere of the tube furnace, the temperature is raised to 330°C at 5°C / min, and the temperature is kept for 2-3h for pre-carbonization.

[0038] (2) Mix the pre-carbonized material obtained in step (1) with potassium hydroxide at a mass ratio of 1:1, and in a tube furnace nitrogen atmosphere, heat up to 750°C at 5°C / min for carbonization, and keep warm for 2-3h , cooled to room temperature.

[0039] (3) The material obtained in step (2) was washed several times with 1M hydrochloric acid, washed with deionized water until neutral, dried, and pulverized by ball milling to obtain a crab shell-based hierarchical porous carbon material.

[0040] (4) Mix the prepared crab shell-based hierarchical porous carbon with magnesium acetate in an aqueous solution according to a certain ratio to form solution A. The ratio depends on the set doping amount of nano-magnesium oxide in the carbon m...

Embodiment 2

[0047] (1) Crab shells are used as raw materials, washed, dried, and pulverized. In the nitrogen atmosphere of the tube furnace, the temperature is raised to 330°C at 5°C / min, and the temperature is kept for 2-3h for pre-carbonization.

[0048] (2) Mix the pre-carbonized material obtained in step (1) with potassium hydroxide at a mass ratio of 1:1, and in a tube furnace nitrogen atmosphere, heat up to 750°C at 5°C / min for carbonization, and keep warm for 2-3h , cooled to room temperature.

[0049] (3) The material obtained in step (2) was washed several times with 1M hydrochloric acid, washed with deionized water until neutral, dried, and pulverized by ball milling to obtain a crab shell-based hierarchical porous carbon material.

[0050] (4) Mix the prepared crab shell-based hierarchical porous carbon with magnesium acetate in an aqueous solution according to a certain ratio to form solution A. The ratio depends on the set doping amount of nano-magnesium oxide in the carbon m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com