Tissue engineering cartilage framework material, as well as preparation method and device thereof

A scaffold material and tissue engineering technology, used in bone implants, medical science, prostheses, etc., can solve the problem of not having the characteristics of the calcification layer of the fibrous structure arranged horizontally on the surface of the cartilage, affecting the fusion of the graft and the surrounding tissue, increasing the amount of cartilage compressive strength and other issues, to achieve the effect of improving wear resistance, preventing moisture loss, and maintaining high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1. Preparation of natural cartilage matrix: 10-200mm 3 Mammalian articular cartilage pieces of the same size without perichondrium are frozen in liquid nitrogen for 3 hours, then transferred to a pre-cooled pulverizer for pulverization, dissolved in acetic acid solution with a volume concentration of 1%, and vacuum freeze-dried to obtain cartilage matrix;

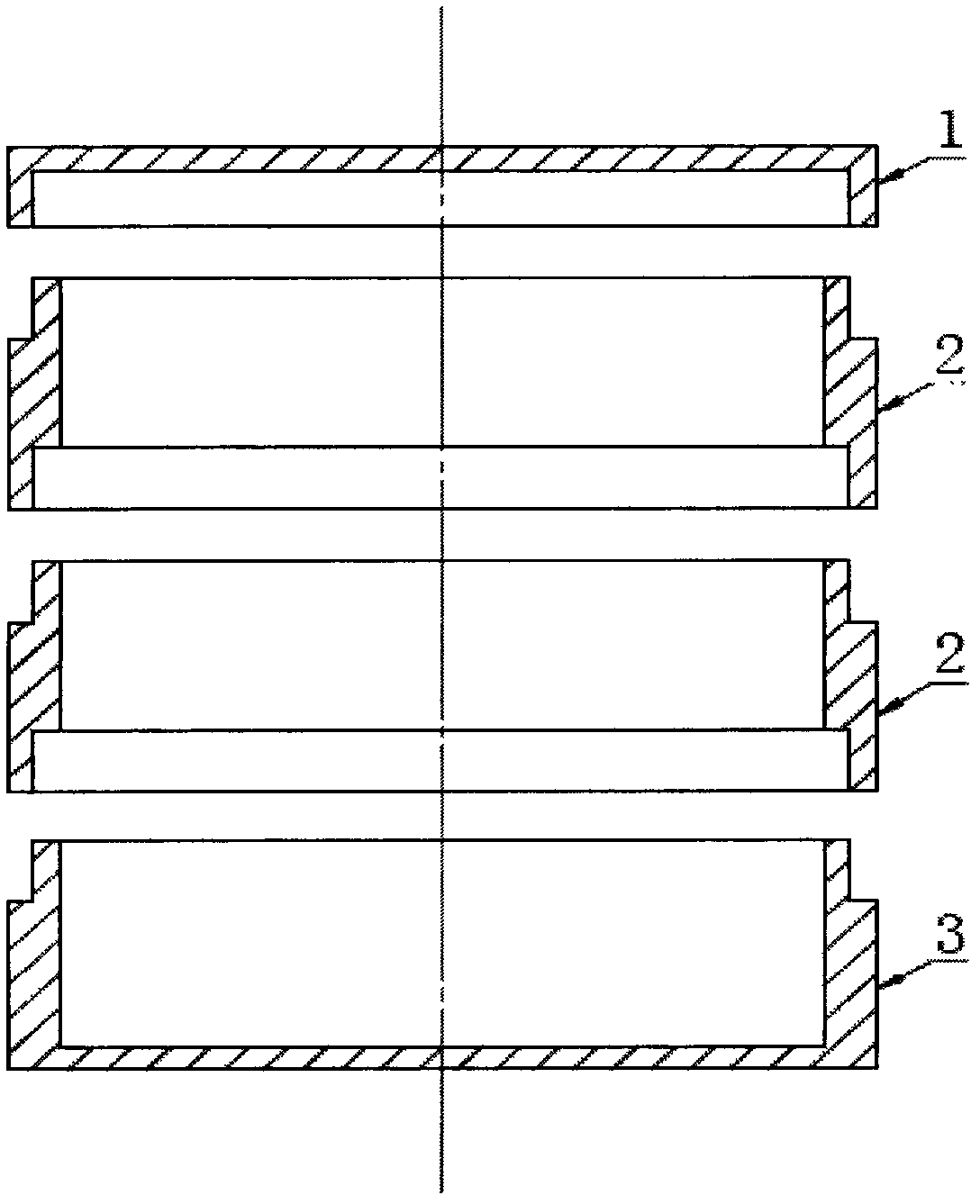

[0028] Step 2, preparation of calcified layer: dissolve freeze-dried cartilage matrix, GAG and X-type collagen in 1% acetic acid solution so that the final concentrations are 5 mg / ml, 8 mg / ml and 5 mg / ml respectively, and use hydrogen Adjust the pH of the calcium oxide solution to neutral to obtain a cartilage matrix solution; fully mix the calcined bone powder (0.2 mm in particle size) with the cartilage matrix solution at a concentration of 0.4 g / ml, inject it into the bottom box of the culture vessel, and make the thickness of the gel layer 4 mm, add Cover and wait for the gel solution to solidify at 37°C, t...

Embodiment 2

[0033] Step 1. Preparation of natural cartilage matrix: 10-200mm 3 Mammalian articular cartilage pieces of the same size without perichondrium are frozen in liquid nitrogen for 3 hours, then transferred to a pre-cooled pulverizer for pulverization, dissolved in acetic acid solution with a volume concentration of 1%, and vacuum freeze-dried to obtain cartilage matrix;

[0034] Step 2, preparation of calcified layer: dissolve freeze-dried cartilage matrix, GAG and X-type collagen in 1% acetic acid solution so that the final concentrations are 10 mg / ml, 9 mg / ml and 10 mg / ml respectively, and use hydrogen Adjust the pH of the calcium oxide solution to neutral to obtain the cartilage matrix solution; fully mix the calcined bone powder (Bayameng brand hydroxyapatite bone powder particle size 0.1mm) and the cartilage matrix solution at a concentration of 0.15g / ml, and pour it into the bottom of the culture vessel box, so that the thickness of the gel layer is 2mm, and after the gel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com