Method for preparing bismuth ferrite functional film by short wave ultraviolet irradiation pretreatment

A technology of ultraviolet light and bismuth ferrite, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of large film shrinkage, film cracks, etc., and achieve a compact and smooth surface, simple process, and low experimental conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

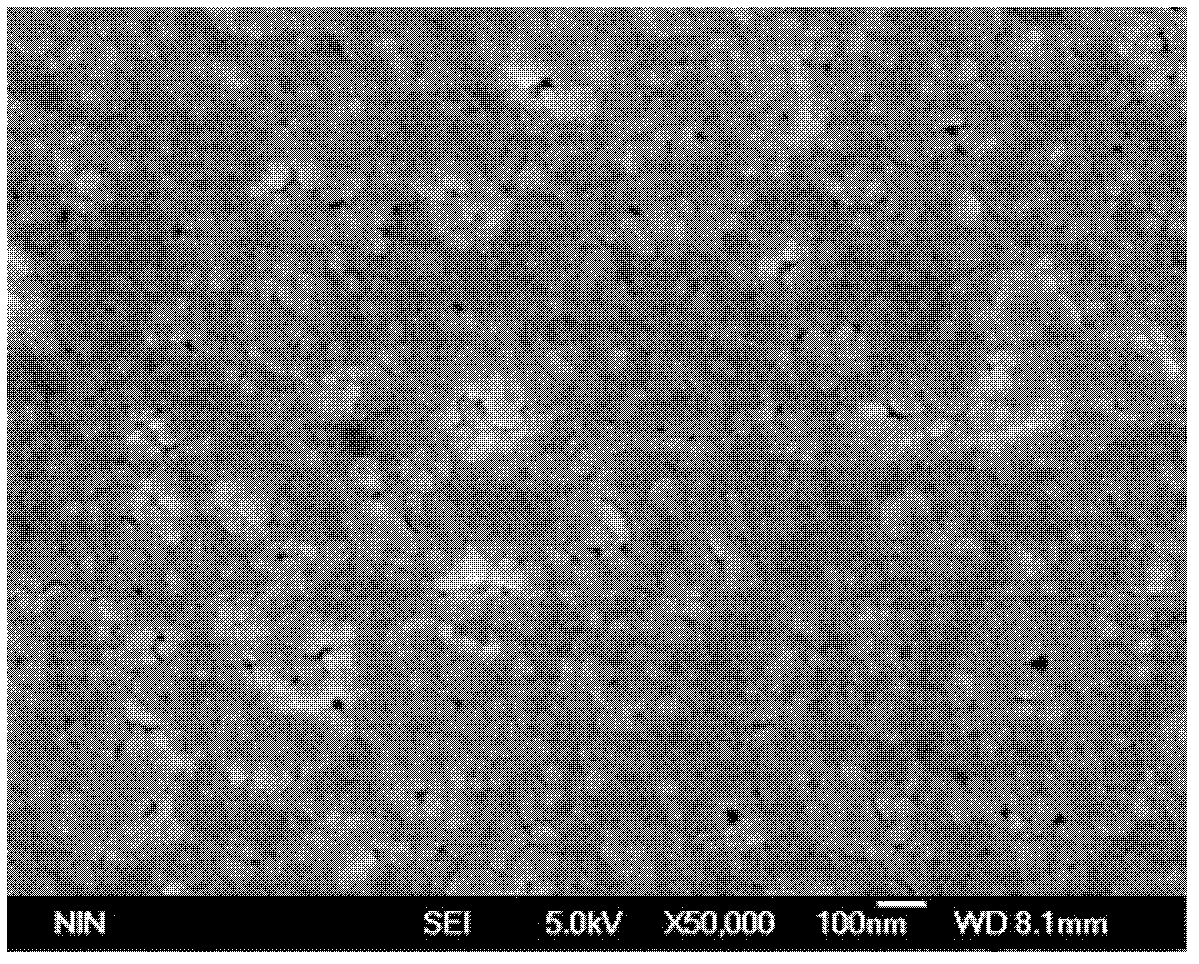

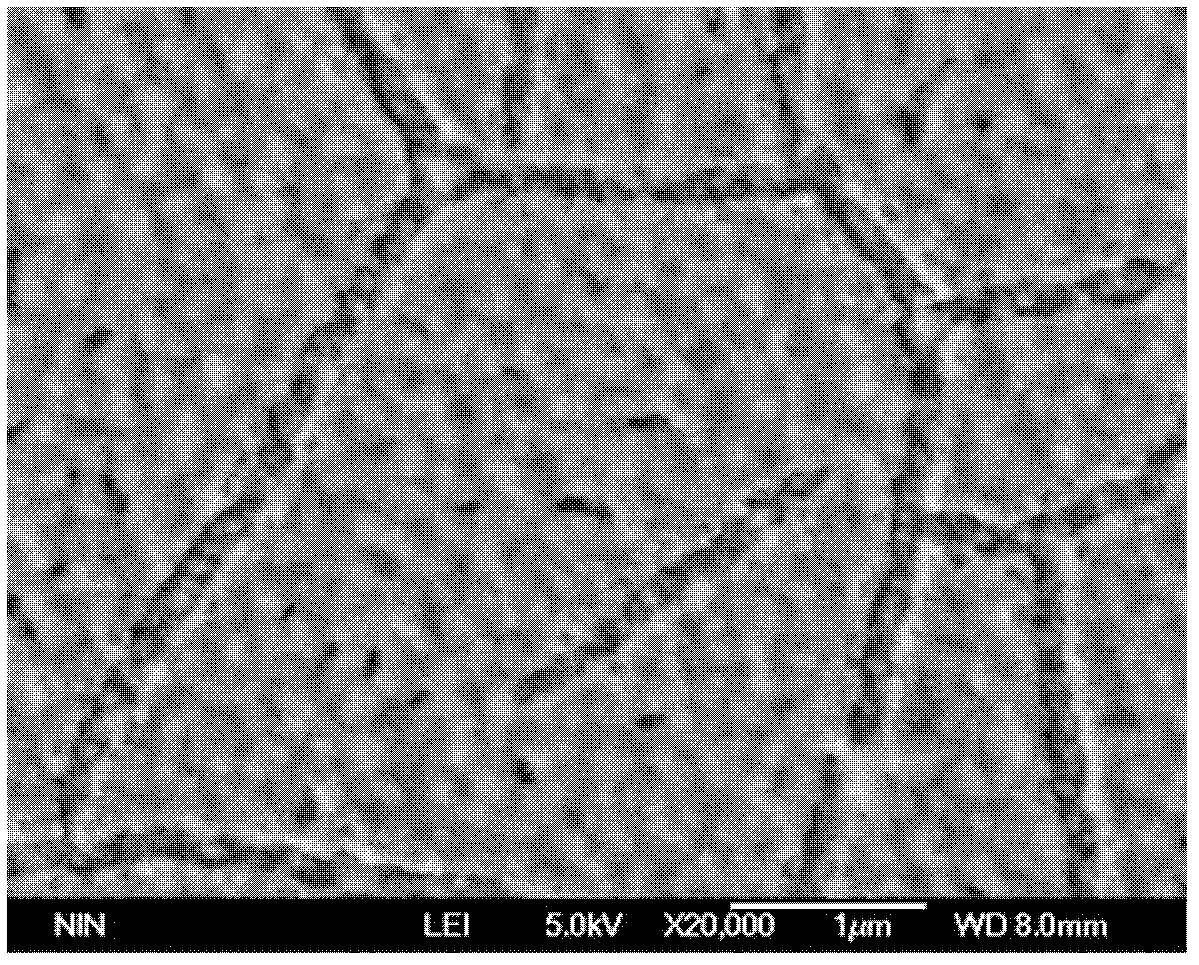

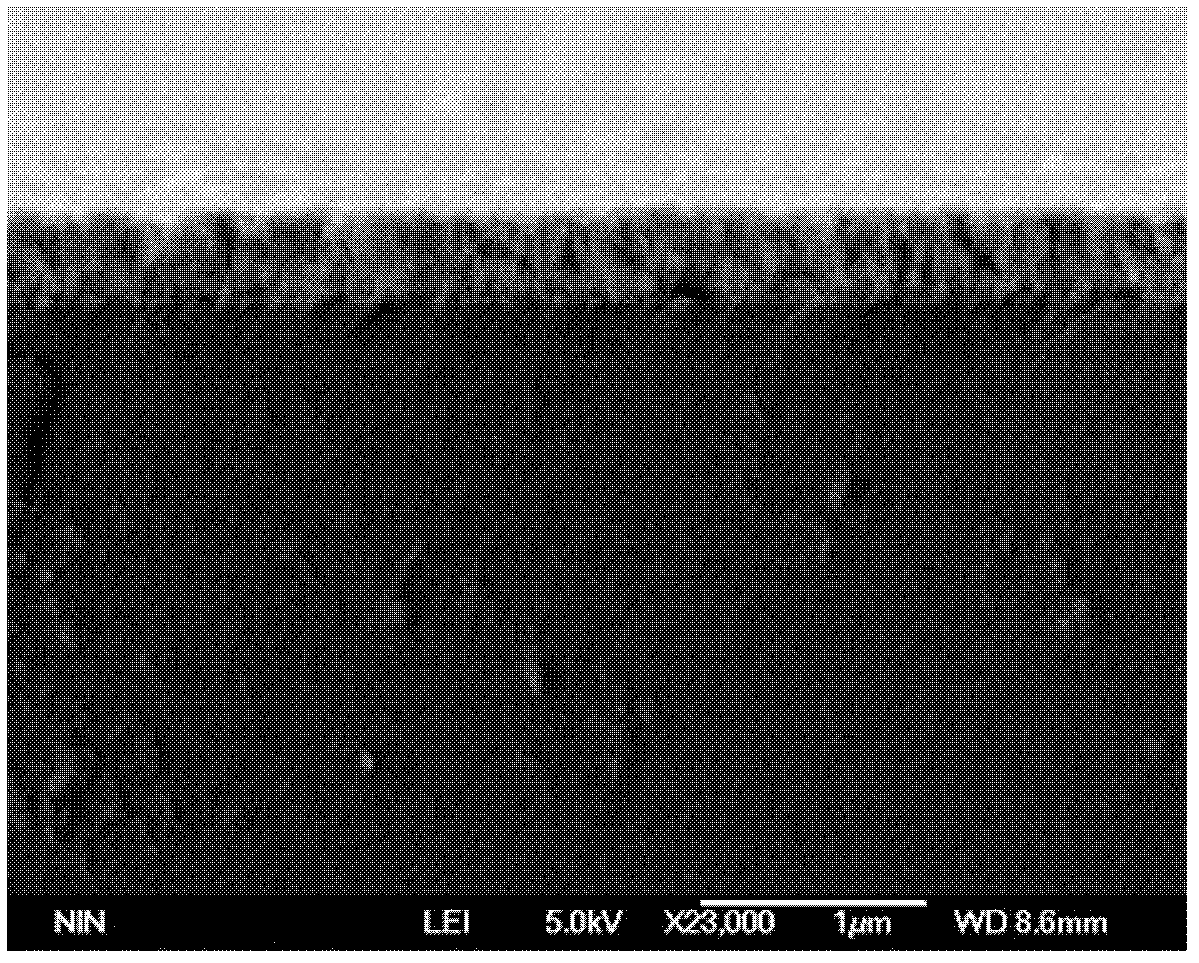

Image

Examples

Embodiment 1

[0017] Step 1: Configuration of precursor solution. Weigh Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, measure glacial acetic acid, be dissolved in distilled water and be configured into a 200ml solution. Stir at room temperature until it is completely clear, add citric acid, continue to stir at room temperature until the solution is clear, and then obtain the precursor solution. In the precursor solution, the bismuth ion concentration is 0.01mol / L, the iron ion concentration is 0.045mol / L, The concentration is 0.02mol / L, and the volume fraction of glacial acetic acid is 2%.

[0018] Step 2: Functionalization of the substrate. The substrates were ultrasonically washed in deionized water, acetone, and absolute ethanol for 10 min. After irradiating with ultraviolet light for 20 min, soak in OTS (1vol%)-toluene solution for 30 min to prepare an OTS monolayer film, and dry at 120 °C for 5 min to remove organic matter. Finally, it was irradiated under ultraviolet light for 40 ...

Embodiment 2

[0024] Step 1: Configuration of precursor solution. Weigh Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, measure glacial acetic acid, be dissolved in distilled water and be configured into a 200ml solution. Stir at room temperature until it is completely clear, add citric acid, continue to stir at room temperature until the solution is clear, and then obtain the precursor solution. In the precursor solution, the bismuth ion concentration is 0.01mol / L, the iron ion concentration is 0.01mol / L, The concentration is 0.02mol / L, and the volume fraction of glacial acetic acid is 2%.

[0025] Step 2: Functionalization of the substrate. The substrates were ultrasonically washed in deionized water, acetone, and absolute ethanol for 10 min. After irradiating with ultraviolet light for 20 min, soak in OTS (1vol%)-toluene solution for 30 min to prepare an OTS monolayer film, and dry at 120 °C for 5 min to remove organic matter. Finally, it was irradiated under ultraviolet light for 40 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com