Method for preparing neutral bleaching xylanase

A xylanase and neutral technology, which is applied in the field of preparation of neutral bleaching xylanase, can solve the problems of level dyeing, low dyeing defective rate, low bulkiness of cottonseed hulls and low whiteness. Increase insignificant problems such as saving dyes, reducing the rate of defective dyeing, and improving hand and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

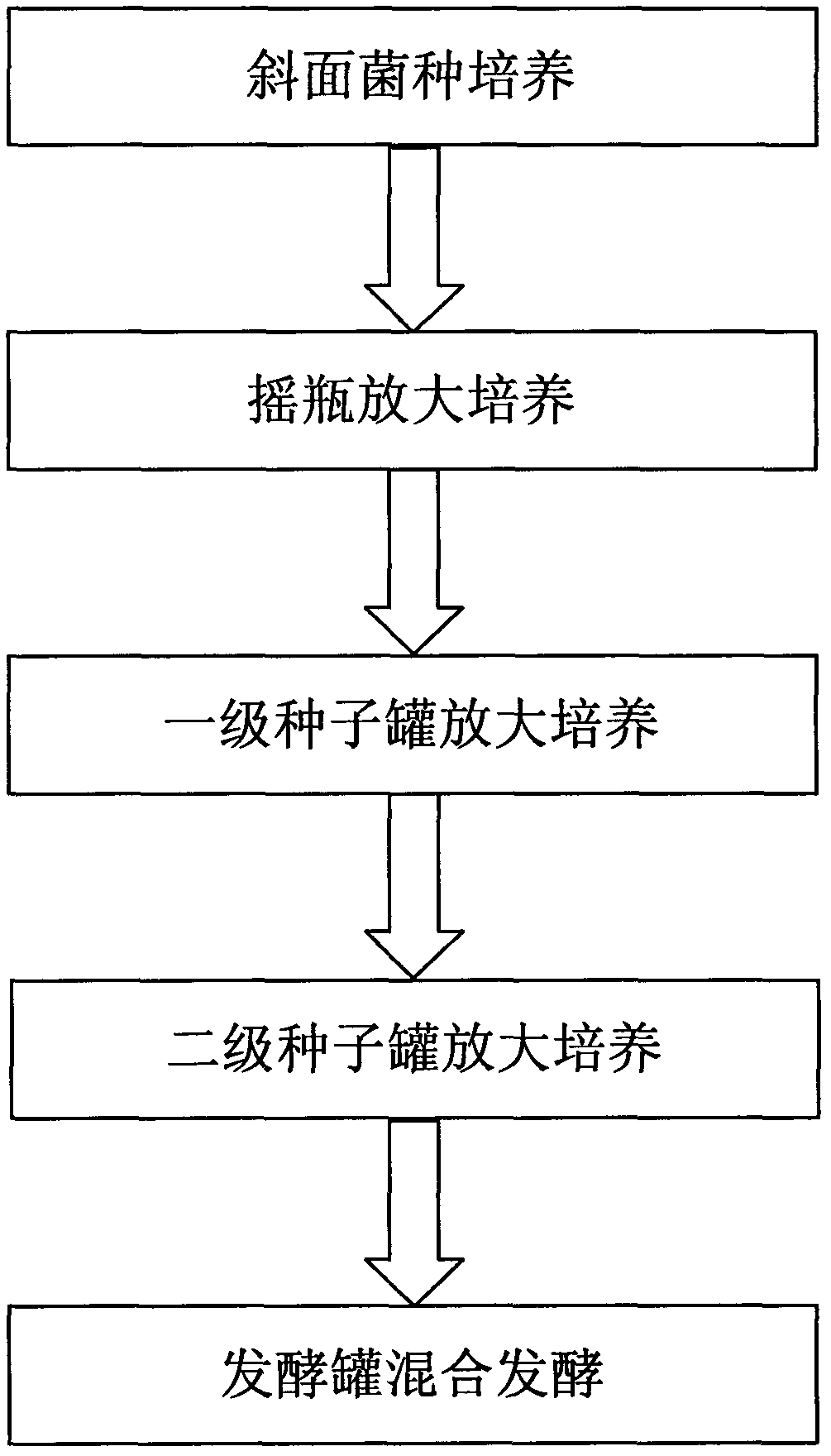

[0026] 1. Bacteria culture on inclined plane

[0027] Pichia pastoris is used as the production strain, and the BMGY slant medium used includes: 1% yeast powder, 2% peptone, 1% glycerol, 1.34% YNB, adjust the pH to 6.0, then add 2.5% agar, and culture at 30°C For 48 hours, store in a 4°C refrigerator.

[0028] 2. Shake flask scale-up culture

[0029] Pick a single colony and inoculate it into a Erlenmeyer flask containing 500ml of BMGY, cultivate overnight at 30°C and 250r / min, and when the OD reaches 2-6, add the culture into the tank.

[0030] 3. Amplified cultivation of primary seed tanks

[0031] According to the ingredients of the first-level seed tank formula, trace elements such as magnesium, iron, and magnesium sulfate are added after feeding. After inoculation to the first-level seed tank for amplified cultivation, the tank pressure is 0.07Mpa, and the air volume is 16m 3 / h, without stirring, with a natural pH value, and cultured at 29°C for 15 hours. 0 hours af...

Embodiment 2

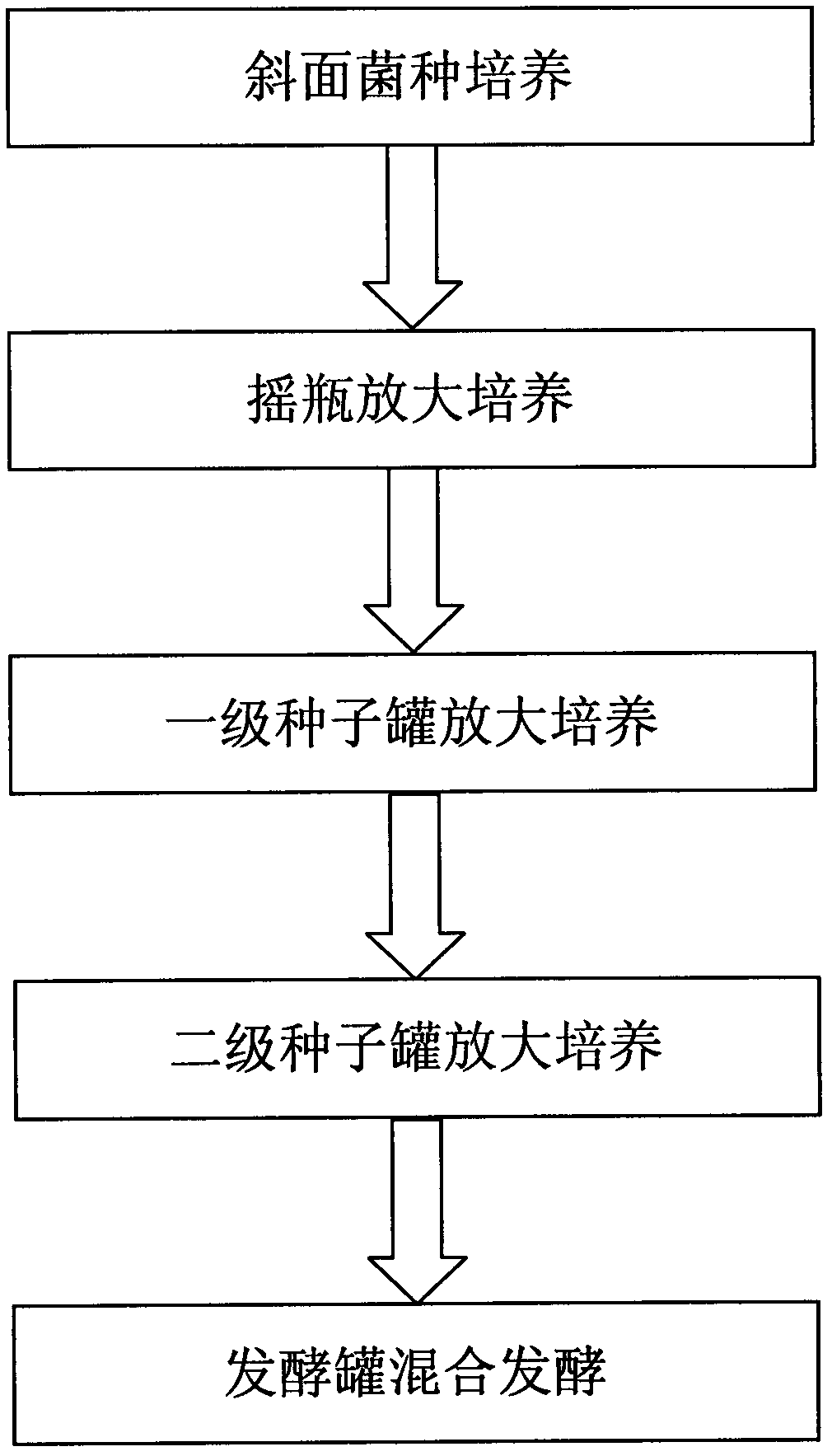

[0040] 1. Bacteria culture on inclined plane

[0041] Pichia pastoris is used as the production strain, and the BMGY slant medium used includes: 1% yeast powder, 2% peptone, 1% glycerol, 1.34% YNB, adjust the pH to 6.0, then add 2.5% agar, and culture at 30°C For 48 hours, store in a 4°C refrigerator.

[0042] 2. Shake flask scale-up culture

[0043] Pick a single colony and inoculate it into a Erlenmeyer flask containing 500ml of BMGY, cultivate overnight at 30°C and 250r / min, and when the OD reaches 2-6, add the culture into the tank.

[0044] 3. Amplified cultivation of primary seed tanks

[0045] According to the ingredients of the first-level seed tank formula, trace elements such as magnesium, iron, and magnesium sulfate are added after feeding, and the raw materials in the tank are fixed to 150L. The actual consumption adopts direct air intake to ensure that the volume after the actual consumption is 180L, and the pH is 5.0. After disinfection, inoculate to the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com