Method for recycling vanadium from vanadium-containing steel slag

A steel slag and tailing slag technology, applied in the field of vanadium recovery, can solve the problems of difficult separation, reduce waste water production and discharge, and low leaching rate, and achieve the effects of reducing reaction temperature, raw material cost, and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

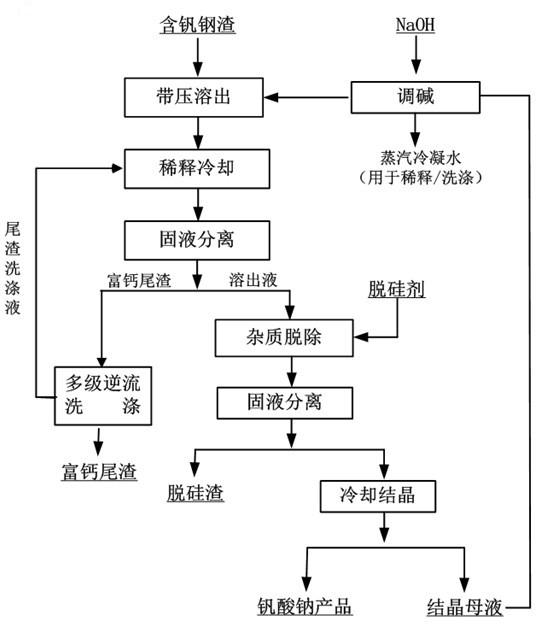

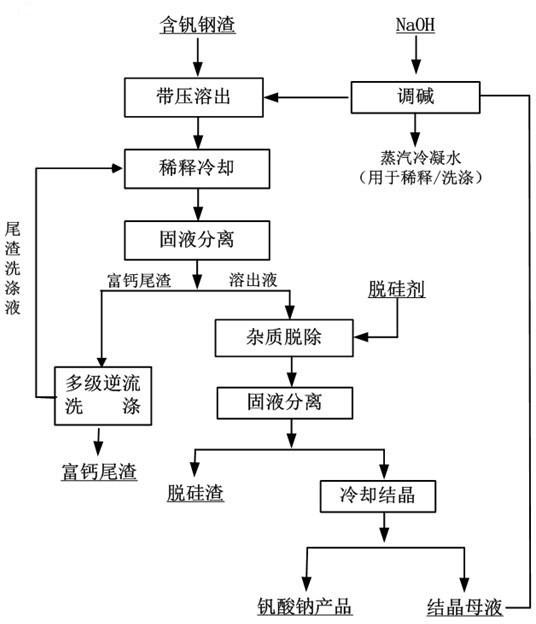

[0026] Example 1: figure 1 As shown, the method for recovering vanadium from vanadium-containing steel slag adopts the following process steps.

[0027] (1) Response (i.e. figure 1 stripping under pressure): in the autoclave, add vanadium-containing steel slag and 30wt% NaOH solution; wherein, sodium hydroxide solution: vanadium-containing steel slag=4:1 (mass), vanadium-containing steel slag contains V 2 o 5 3.6wt%; heated to 250°C, the pressure inside the kettle was 2.4MPa, and reacted for 4h to obtain NaOH, Na 3 VO 4 、Na 2 SiO 4 The reaction slurry mixed with the solution of etc. and calcium-rich tailings;

[0028] (2) Dilution: The reaction slurry is diluted with a diluent until the concentration of sodium hydroxide is 200g / L to obtain a mixed slurry containing iron-rich tailings, sodium hydroxide, and sodium vanadate; the diluent uses the previous process step ( 3) Obtain washing liquid;

[0029] (3) Solid-liquid separation: filter and separate the mixed slurry a...

Embodiment 2

[0033] Embodiment 2: This method for recovering vanadium from vanadium-containing steel slag adopts the following process steps.

[0034](1) Reaction: In the autoclave, add vanadium-containing steel slag and 40wt% NaOH solution; wherein, sodium hydroxide solution: vanadium-containing steel slag=5:1 (mass), vanadium-containing steel slag contains V 2 o 5 4.6wt%; heated to 230°C, the pressure inside the kettle was 1.6MPa, and reacted for 3 hours to obtain a reaction slurry;

[0035] (2) Dilution: The reaction slurry is diluted with a diluent until the concentration of sodium hydroxide is 250g / L to obtain a mixed slurry; the diluent uses the previous process step (3) to obtain a washing liquid;

[0036] (3) Solid-liquid separation: filter and separate the mixed slurry at 100°C to obtain eluate and calcium-rich tailings; the calcium-rich tailings are subjected to multi-stage countercurrent washing with water, and the obtained washing liquid is used in the next process Dilution ...

Embodiment 3

[0040] Embodiment 3: This method for recovering vanadium from vanadium-containing steel slag adopts the following process steps.

[0041] (1) Reaction: In the autoclave, add vanadium-containing steel slag and 50wt% NaOH solution; wherein, sodium hydroxide solution: vanadium-containing steel slag=4:1 (mass), vanadium-containing steel slag contains V 2 o 5 4.5wt%; heated to 200°C, the pressure inside the kettle was 0.4MPa, reacted for 2h, and finally obtained the reaction slurry;

[0042] (2) Dilution: the reaction slurry is diluted with a diluent until the concentration of sodium hydroxide is 350g / L to obtain a mixed slurry; the diluent is obtained from the washing solution in step (3) of the previous process;

[0043] (3) Solid-liquid separation: filter and separate the mixed slurry at 110°C to obtain eluate and calcium-rich tailings; the calcium-rich tailings are washed in multi-stage countercurrent with clean water, and the obtained washing liquid is used in the next step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com