Compound herbicide

A herbicide and adjuvant technology, applied in the directions of herbicides, algaecides, biocides, biocides, etc., can solve problems such as no literature on the compounding and application of diflufenacil and oxyfluorfen , to achieve the effect of overcoming weed resistance, increasing action sites and improving efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: (50% diflufenamide · oxyfluorfen wettable powder)

[0035] Formula: diflufenican, 20%; oxyfluorfen, 30%; wetting agent, sodium lauryl sulfate, 4%; dispersing agent, sodium lignosulfonate, 6%; filler, white carbon black, 8% , kaolin, balance.

[0036] 2. Water dispersible granules

[0037] Preparation method: According to the ratio of the formula in the example, add the active ingredients diflufenican and oxyfluorfen to the carrier, and add surfactant and other functional additives to it, mix, and add 10 to 25 % of water, then kneaded, granulated, dried, and sieved to obtain water-dispersible granules; or the pulverized powder was sprayed with water in a boiling granulator, granulated, dried, and then sieved to obtain the product . The main equipments are mixer, jet mill, kneader, extrusion granulator, drying room or fluidized bed drying, or boiling granulator, screening machine. Example 2: (80% diflufenican · oxyfluorfen water dispersible granules)

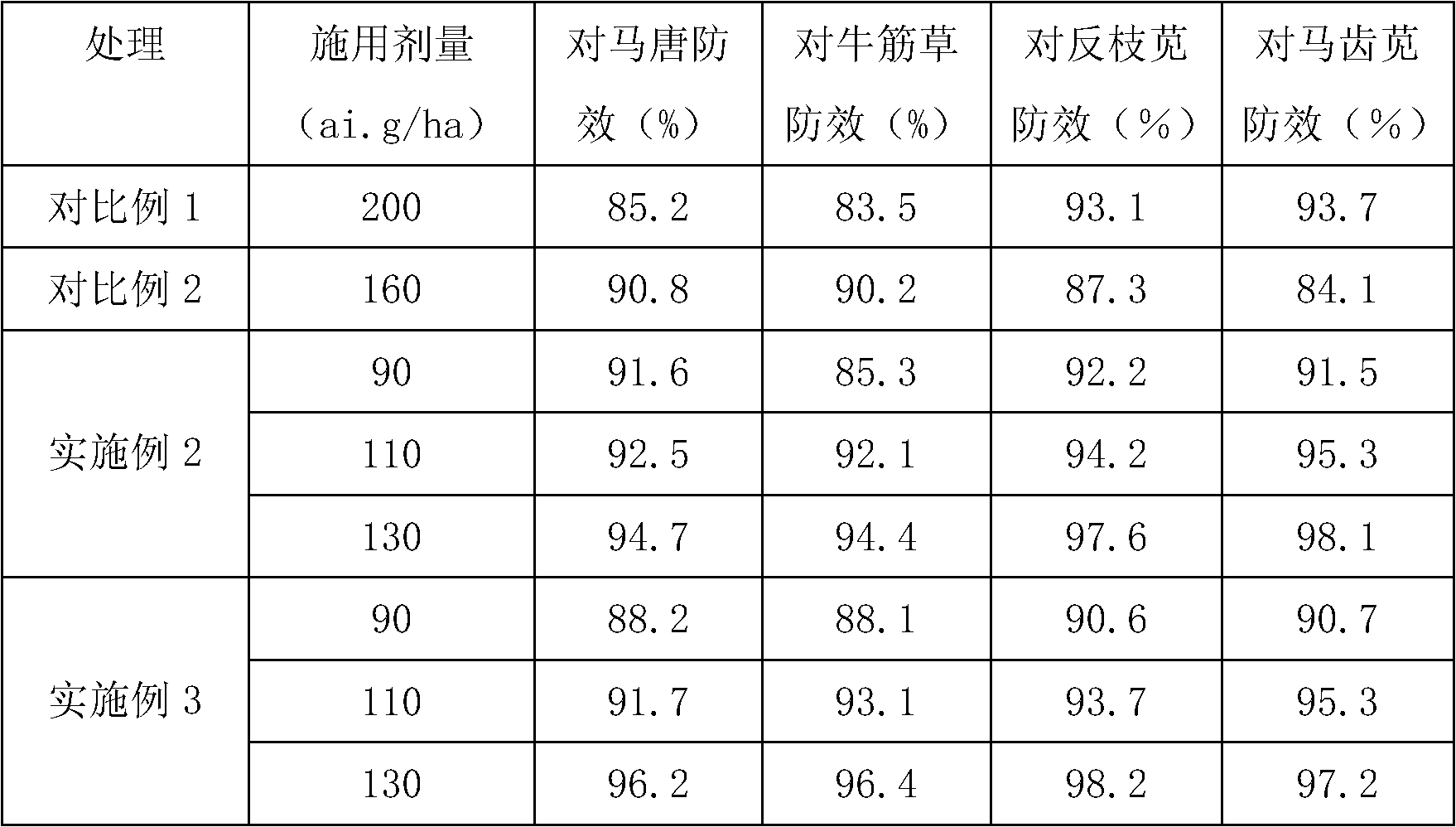

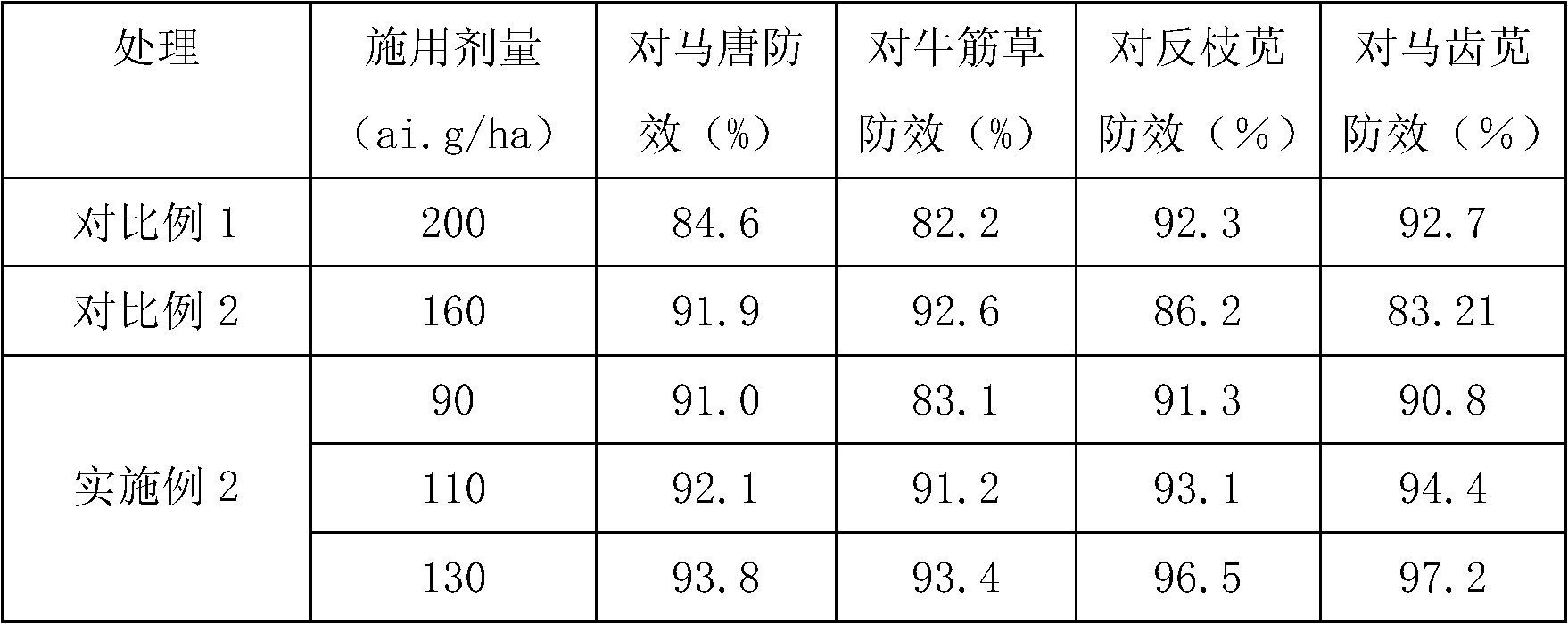

Embodiment 2

[0037] Preparation method: According to the ratio of the formula in the example, add the active ingredients diflufenican and oxyfluorfen to the carrier, and add surfactant and other functional additives to it, mix, and add 10 to 25 % of water, then kneaded, granulated, dried, and sieved to obtain water-dispersible granules; or the pulverized powder was sprayed with water in a boiling granulator, granulated, dried, and then sieved to obtain the product . The main equipments are mixer, jet mill, kneader, extrusion granulator, drying room or fluidized bed drying, or boiling granulator, screening machine. Example 2: (80% diflufenican · oxyfluorfen water dispersible granules)

[0038] Formulation: Diflufenamide, 25%; Oxyflufen, 55%; Wetting agent Sodium Lauryl Sulfate, 4%; Dispersant Alkylnaphthalene Sulfonate Formaldehyde Condensate, 6%; Filler Diatom Soil, surplus.

[0039] 3. Water suspending agent

[0040] Preparation method: according to the proportion of the formula, put ...

Embodiment 3

[0041] Example 3: (40% diflufenican · oxyfluorfen aqueous suspension concentrate)

[0042]Formula: diflufenican, 10%; oxyfluorfen, 30%; emulsifier Nongru OP-10, 2%; dispersant polycarboxylate, 5%; thickeners choose xanthan gum and silicic acid Magnesium aluminum, the dosage is 0.1% and 1% respectively; antifreeze agent ethylene glycol, 3%; antifoaming agent silicone compound, 0.5%; water, balance.

[0043] 4. Cream

[0044] Preparation method: Add the active ingredients diflufenican and oxyfluorfen into the carrier according to the ratio of the formula in the example, and add surfactant and other functional auxiliaries therein, and stir and mix evenly in a stirring mixing tank. The stirring and mixing kettle can be enamel reaction kettle, stainless steel stirring kettle, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com