Method for separating and purifying erythritol from mother liquid obtained after repeated crystallization of erythritol

A technology of erythritol and multiple crystallization, which is applied in the field of bioengineering, can solve the problems of no mention of erythritol mother liquor treatment method, short chromatographic resin life, and no economic value, so as to reduce membrane pollution load and reduce Concentration, the effect of reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

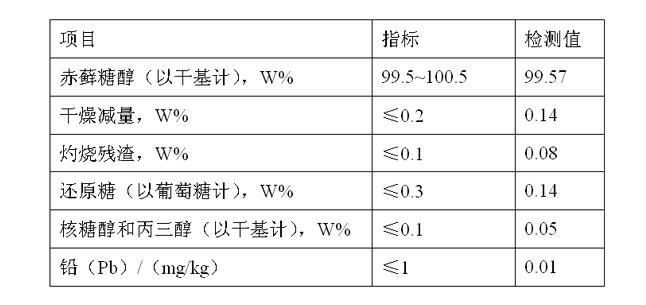

Embodiment 1

[0022] 1. Pretreatment: Take the mother liquor after multiple crystallizations of erythritol and dilute it with pure water to obtain a 20% Brix dilution;

[0023] 2. Ultrafiltration treatment: Ultrafiltration treatment is performed on the diluted solution obtained above. The pressure before the membrane is 0.2mpa, the pressure behind the membrane is 0.18mpa, and the membrane flux is 300-400ml / min?㎡. The obtained permeate Brix was 19%, and the light transmittance was 9.7%.

[0024] 3. Nanofiltration treatment: Add the above-mentioned permeate into the feed barrel of multi-connected nanofiltration membranes with a molecular weight cut-off of 500D-800D. The working pressure is: 1.8mpa in front of the membrane, 1.75mpa behind the membrane, the flow rate of the dialysate is 150 ml / min?㎡, and the flow rate of the concentrate is 4.7L / min?㎡. The resulting dialysate had a Brix of 9.1%, a light transmittance of 84%, and an erythritol content of 76.8% as detected by HPLC.

[0025] 4....

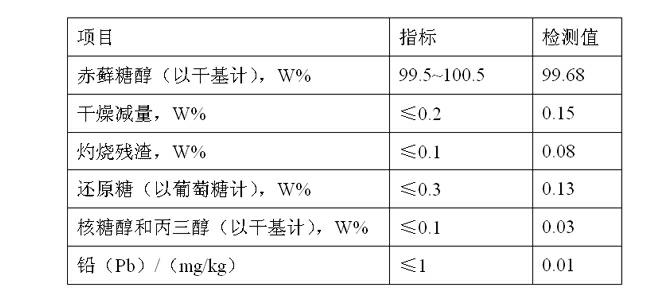

Embodiment 2

[0031] 1. Pretreatment: Take the mother liquor after multiple crystallizations of erythritol and dilute it with pure water to obtain a 31% Brix dilution;

[0032] 2. Ultrafiltration treatment: Ultrafiltration treatment is performed on the diluted solution obtained above. The ultrafiltration membrane with a cut-off of 300,000 D is used, the pressure before the membrane is controlled to be 0.25mpa, the pressure behind the membrane is 0.23mpa, and the membrane flux is 250-300ml / min?㎡. The obtained permeate Brix was 24%, and the light transmittance was 7.7%.

[0033] 3. Nanofiltration treatment: Add the above-mentioned permeate into the feed barrel of multi-connected nanofiltration membranes with a molecular weight cut-off of 500D-800D. The working pressure is: 2.3mpa in front of the membrane, 1.5mpa behind the membrane, the flow rate of the dialysate is 120ml / min?㎡, and the flow rate of the concentrate is 4.6L / min?㎡. The obtained dialysate Brix is 10.2%, the transmittance is...

Embodiment 3

[0040] 1. Pretreatment: Take the mother liquor after multiple crystallizations of erythritol and dilute it with pure water to obtain a 39% dilution of Brix;

[0041] 2. Ultrafiltration treatment: Ultrafiltration treatment is performed on the diluted solution obtained above. The pressure before the membrane is 0.32mpa, the pressure behind the membrane is 0.3mpa, and the membrane flux is 150-220ml / min?㎡. The obtained permeate Brix was 26%, and the transmittance was 5.6%.

[0042] 3. Nanofiltration treatment: Add the above-mentioned permeate into the feed barrel of multi-connected nanofiltration membranes with a molecular weight cut-off of 500D-800D. The working pressure is: 1.8mpa in front of the membrane, 1.75mpa behind the membrane, the flow rate of the dialysate is 79ml / min?㎡, and the flow rate of the concentrate is 4.6L / min?㎡. The resulting dialysate had a Brix of 12.6%, a light transmittance of 72%, and an erythritol content of 88% as detected by HPLC.

[0043] 4. Activat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com