High polymer with N-dicarboxyl in side chains and application thereof

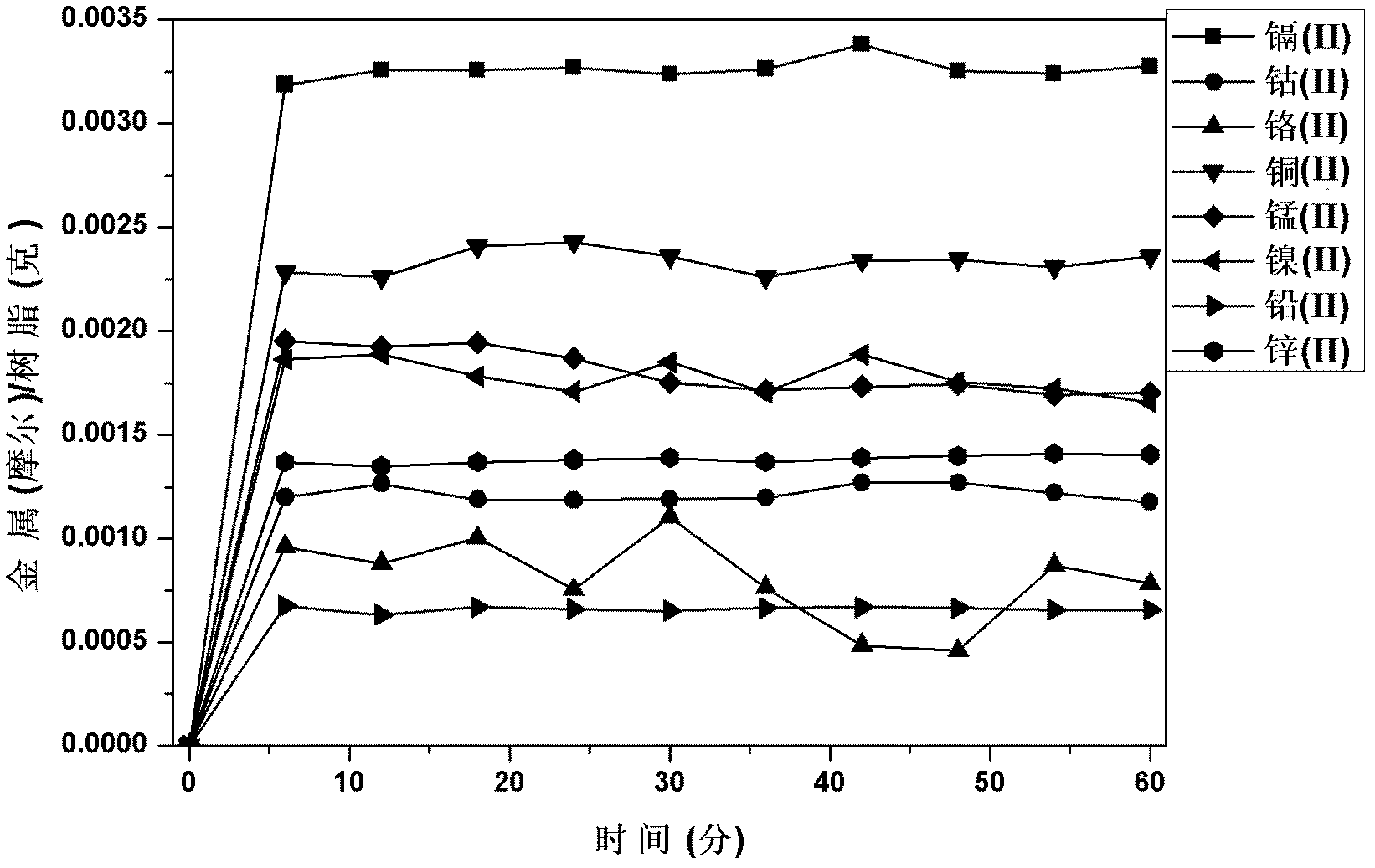

A double carboxyl group and polymer technology, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problems that chemical treatment methods cannot meet the needs, and achieve fast adsorption speed, convenient post-treatment, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: laboratory preparation of polymer resin with N-biscarboxyl groups in the side chain

[0025] 100g of disodium iminodiacetate (IDA) was dissolved in 220g of water, and after complete dissolution, 50g of glycidyl methacrylate (GMA) was slowly added to react for 0.5h at a reaction temperature of 80°C. Add 20g of cross-linking agent N, N'-methylenebisacrylamide (MBA) and continue to stir until completely dissolved, keep the reaction temperature at 80°C, lower the temperature to 55°C appropriately, and use potassium persulfate / sodium bisulfite initiator ( Mass ratio 1:1, concentration 1%), polymerize to obtain the target polymer, and the polymerization yield is 99%.

[0026] The target polymer cannot be dissolved in water and common organic solvents (acetone, ethanol, toluene, benzene, methylene chloride, DMF, etc.).

[0027] The target polymer is analyzed by infrared spectroscopy and thermogravimetric analysis. The results of infrared spectroscopy show that the ...

Embodiment 2

[0035] Example 2: laboratory preparation of polymer resin with N-biscarboxyl groups in the side chain

[0036] 100g of disodium iminodiacetate (IDA) was dissolved in 220g of water, and after complete dissolution, 50g of glycidyl methacrylate (GMA) was slowly added to react for 0.5h at a reaction temperature of 80°C. Add 25g of cross-linking agent N, N'-methylenebisacrylamide (MBA) and continue to stir until it is completely dissolved, keep the reaction temperature at 80°C, lower the temperature to 55°C appropriately, and use potassium persulfate / sodium bisulfite initiator ( Mass ratio 1:1, concentration 1%), polymerize to obtain the target polymer, and the polymerization yield is 99%.

[0037] The target polymer cannot be dissolved in water and common organic solvents (acetone, ethanol, toluene, benzene, methylene chloride, DMF, etc.).

[0038]The target polymer is analyzed by infrared spectrum and thermogravimetric analysis. The infrared spectrum shows that the carboxylate a...

Embodiment 3

[0042] Example 3: laboratory preparation of polymer resins with N-dicarboxylates in side chains

[0043] 100g of disodium iminodiacetate (IDA) was dissolved in 220g of water, and after complete dissolution, 50g of glycidyl methacrylate (GMA) was slowly added to react for 0.5h at a reaction temperature of 80°C. Add 18g of cross-linking agent N, N'-methylenebisacrylamide (MBA) and continue to stir until completely dissolved, keep the reaction temperature at 80°C, lower the temperature to 55°C appropriately, and use potassium persulfate / sodium bisulfite initiator ( Mass ratio 1:1, concentration 1%), polymerize to obtain the target polymer, and the polymerization yield is 99%.

[0044] The target polymer cannot be dissolved in water and common organic solvents (acetone, ethanol, toluene, benzene, methylene chloride, DMF, etc.).

[0045] The target polymer is analyzed by infrared spectrum and thermogravimetric analysis. The infrared spectrum shows that the carboxylate anion vibrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com