Method for preparing unsaturated carboxylic acid grafted polypropylene copolymer

A grafted polypropylene, unsaturated technology, applied in the field of preparation of organic macromolecular polymers, can solve the problems of operator eye and skin damage, easy volatilization or sublimation, difficulty in actual production, etc., and achieves low operating pressure and post-processing. Simple, high grafting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

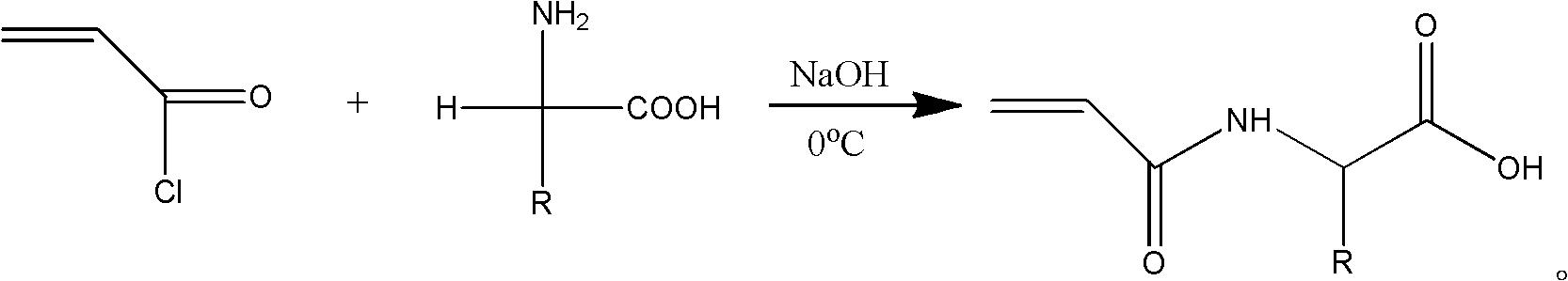

[0030] Dissolve 300 parts by weight of unsaturated carboxylic acid grafting monomer 1-acryloylpyrrolidine-2-carboxylic acid in 280 parts of N, N-dimethylformamide, 100 parts of initiator dibenzoyl peroxide Soluble in 770 parts of interface agent xylene, in N 2 The two solutions were added under atmosphere to a reaction apparatus already charged with 300 parts of copolymerized polypropylene particles and 700 parts of auxiliary grafted monomer styrene. React at 110±2° C. for 30 minutes, cool, filter, wash with methanol and acetone respectively, and dry in vacuum to obtain the final grafted product with a grafting rate of 14.3%.

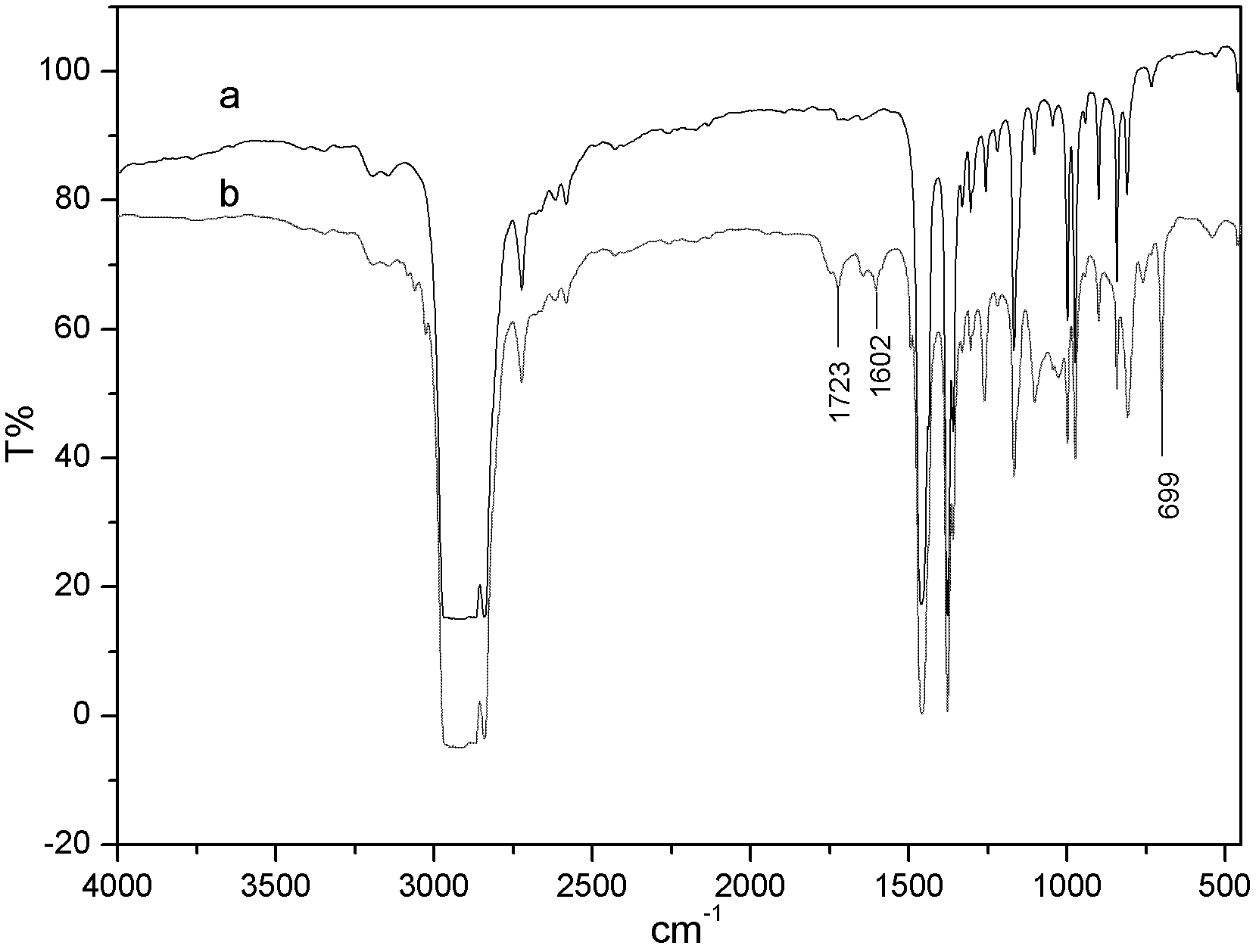

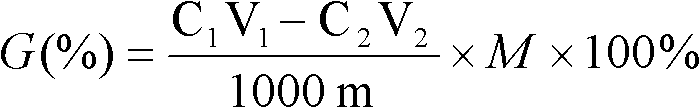

[0031] The method for measuring the grafting rate of unsaturated carboxylic acid in the grafted product of modified polypropylene is a titration method, and the specific method is as follows: firstly, the grafted product is extracted with acetone and methanol for 24 hours to remove possible residual styrene and Unsaturated carboxylic acid homopolymer. ...

Embodiment 2

[0036] Dissolve 150 parts by weight of unsaturated carboxylic acid grafting monomer 1-acryloylpyrrolidine-2-carboxylic acid in 280 parts of N, N-dimethylformamide, 100 parts of initiator dibenzoyl peroxide Soluble in 770 parts of interface agent xylene, in N 2 The two solutions were added under atmosphere to a reaction apparatus already charged with 300 parts of copolymerized polypropylene particles and 350 parts of auxiliary grafted monomer styrene. React at 110±2° C. for 30 minutes, cool, filter, wash with methanol and acetone respectively, and dry in vacuum to obtain the final grafted product with a grafting rate of 6.7%.

Embodiment 3

[0038] Dissolve 45 parts by weight of unsaturated carboxylic acid grafting monomer 1-acryloylpyrrolidine-2-carboxylic acid in 280 parts of N, N-dimethylformamide, 100 parts of initiator dibenzoyl peroxide Soluble in 770 parts of interface agent xylene, in N 2 The two solutions were added under atmosphere to a reaction apparatus already charged with 300 parts of copolymerized polypropylene particles and 105 parts of auxiliary grafted monomer styrene. React at 110±2° C. for 30 minutes, cool, filter, wash with methanol and acetone respectively, and vacuum-dry to obtain the final grafted product with a grafting rate of 5.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com