Double-component imine modified epoxy solvent-free impregnated resin and preparation and use methods

A technology for impregnating resin and epoxy resin, which is applied in the field of high-temperature-resistant epoxy solvent-free impregnating resin and its preparation, can solve the problems of high price, difficulty in dissolving, decreased heat resistance and storage stability of resin, and achieve effective Facilitate transportation and storage, overcome poor solubility, and prolong the use period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

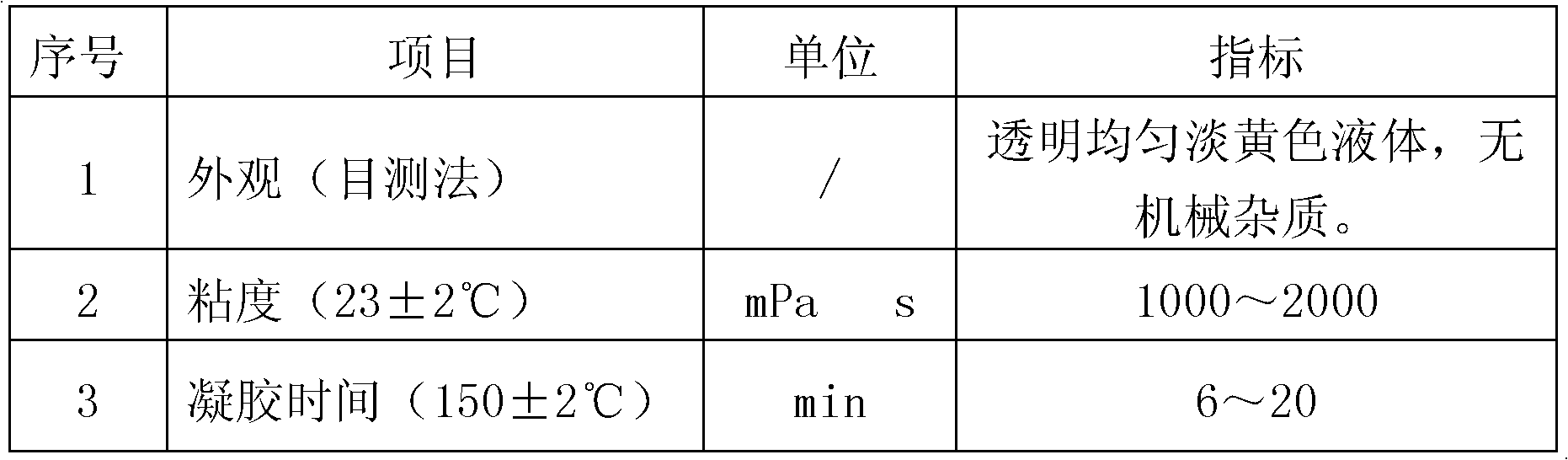

[0047] A two-component Cardo-type imine-modified epoxy anhydride solvent-free high-temperature resistant impregnating resin, which is made by mixing components A and B. Type bismaleimide, their parts by weight are: 100 parts of bisphenol A type epoxy resin, 60 parts of Cardo type bismaleimide; B component is methyltetrahydrophthalic anhydride, diperoxide The parts by weight of cumene and NOVACURE HX-3921HP are: 80 parts of methyltetrahydrophthalic anhydride, 0.3 part of dicumyl peroxide, and 0.5 part of NOVACURE HX-3921HP.

[0048] The specific preparation method is as follows:

[0049] 1. Preparation of component A:

[0050] Preparation of Cardo-type bismaleimides:

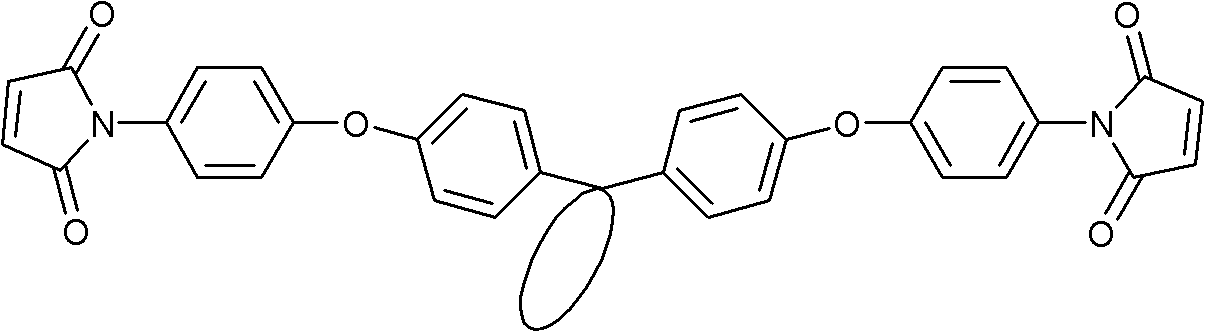

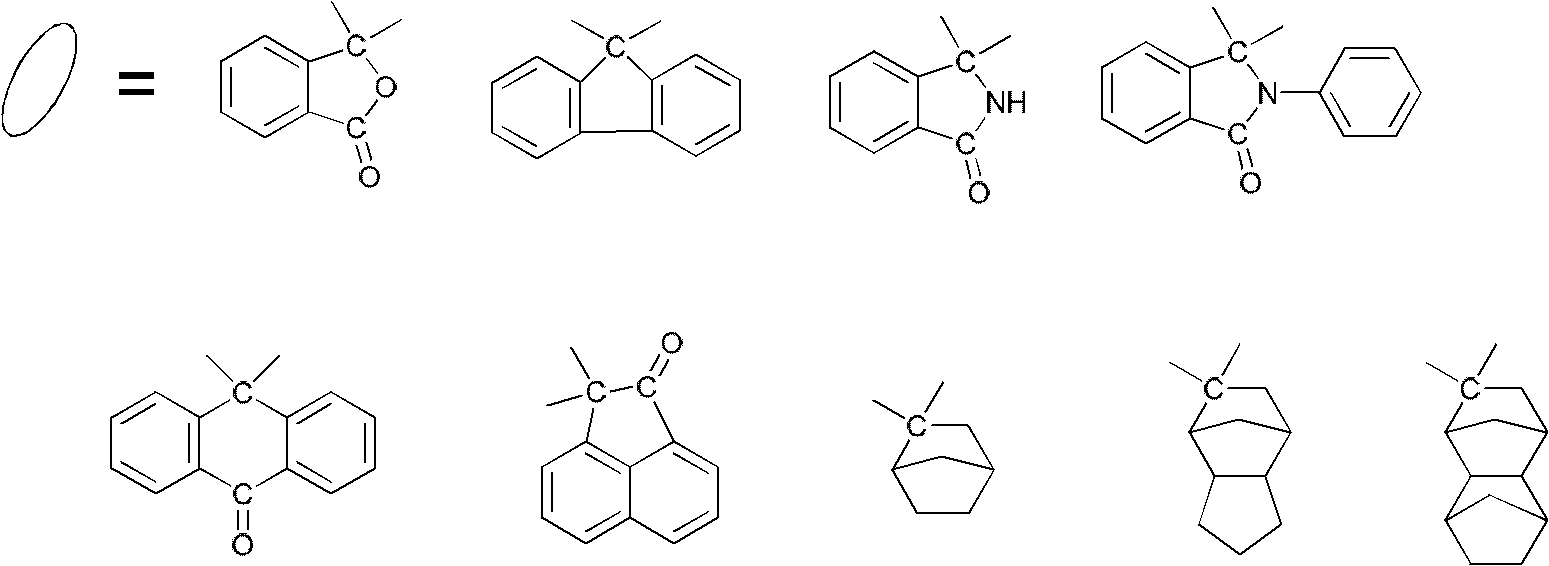

[0051] Add 60 parts of Cardo type bismaleimide in 100 parts of bisphenol A type epoxy resins, synthesize the Cardo type bismaleimide with following structure:

[0052] Mix and stir at 60°C until completely dissolved at a stirring speed of 300-400 rpm, use this as component A, and store in an airtight contain...

Embodiment 2

[0058] A two-component Cardo-type imine-modified epoxy anhydride solvent-free high-temperature resistant impregnating resin, which is made by mixing components A and B, wherein component A is: bisphenol A epoxy resin, bisphenol A Phenol F type epoxy resin, Cardo type bismaleimide, vinyl dioxide cyclohexene epoxy resin, their parts by weight are respectively: 60 parts of bisphenol A type epoxy resin, bisphenol F type ring 40 parts of epoxy resin, 30 parts of Cardo-type bismaleimide, 15 parts of vinyl dioxide cyclohexene epoxy resin; component B is methyl tetrahydrophthalic anhydride, methyl nadic acid anhydride, tertiary benzoic acid peroxide Butyl ester and NOVACURE HX-3721, their parts by weight are: 50 parts of methyl tetrahydrophthalic anhydride, 40 parts of methyl nadic anhydride, 1.5 parts of tert-butyl peroxybenzoate, and 1.5 parts of NOVACURE HX-3721.

[0059] The specific preparation method is as follows:

[0060] 1. Preparation of component A:

[0061] Preparation o...

Embodiment 3

[0070] A two-component Cardo-type imine-modified epoxy anhydride solvent-free high-temperature-resistant impregnation resin, which is composed of A component and B component, of which A component is: novolac epoxy resin, Cardo type double horse Laimide, vinyl dioxide cyclohexene epoxy resin, their parts by weight are respectively: 100 parts of novolak epoxy resins, 28 parts of Cardo type bismaleimides, vinyl dioxide cyclohexene ring 17 parts of epoxy resin; B component is methyl tetrahydrophthalic anhydride, methyl hexahydrophthalic anhydride, tert-butyl peroxybenzoate, NOVACURE HX-3088, and their parts by weight are respectively: 30 parts of methyl tetrahydrophthalic anhydride, 60 parts of methyl hexahydrophthalic anhydride, 1.2 parts of tert-butyl peroxybenzoate, 1.2 parts of NOVACURE HX-3088.

[0071] The specific preparation method is as follows:

[0072] 1. Preparation of component A:

[0073] Preparation of Cardo-type bismaleimides:

[0074] According to the method de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com