Method for separating and purifying mangiferin from mango pericarp

A technology for separation and purification of mangiferin, which is applied in chemical instruments and methods, organic chemistry, preparation of sugar derivatives, etc., can solve the problems of unreported, unguaranteed purity of mangiferin products, extensive process, etc., and achieve high purity and production The process is safe and easy to operate, and the production cycle is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 The present invention carries out the screening determination of influence factor by following test

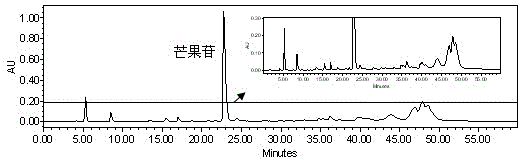

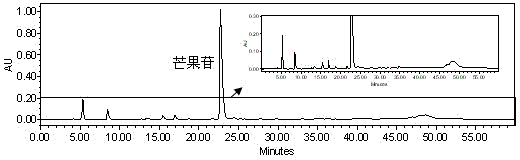

[0023] 1. Selection of purification materials

[0024] Freeze-dried ‘Machesu’ mango fruit materials, including pericarp, pulp, seed coat, and seed kernel, are crushed into fine powder with a mill. Accurately weigh a certain amount of freeze-dried powder, soak in the extract solution (methanol:ethanol:acetone 1:1:1, v / v / v) for 2 hours (solid-liquid ratio 1:20), ultrasonically extract twice, and centrifuge at 10,000 rpm After 10 min, the combined supernatants were used for HPLC analysis of mangiferin. HPLC mobile phase consisted of 2% acetic acid (A) and 0.5% acetic acid:chromatographic acetonitrile (1:1, v / v) (B) with 0-2 min: 95% A, 2-10 min: 95-75% A , 10-40 min: 75-45% A, 40-45 min: 45-10% A, 45-50min: 10-45% A, 50-55 min: 45-95% A, 55-60 min: 95 % A gradient elution, the flow rate was 0.6 ml / min, the stationary phase was Waters C18 column, the column ...

Embodiment 2

[0043] The operation method of separating and purifying mangiferin of the present invention is carried out according to the following steps:

[0044] see figure 1 , (1) Weigh 10 g of 'Lvpimang' pericarp, add 200 ml of extract solution (methanol: ethanol: acetone 1:1:1, v / v / v), soak for 2 h, sonicate for 30 min, filter to get the supernatant , add 200 ml of extract to the filter residue, sonicate for 30 min, filter, combine the two supernatants, evaporate at 45°C to the extract, dissolve the extract in double distilled water to obtain 210 ml of crude extract;

[0045] (2) 210 ml (0.35 mg / ml mangiferin) crude extract, extracted twice with equal volume of ethyl acetate, concentrated the ethyl acetate phase and then extracted once with water, combined the lower phases with rotary evaporation at 45°C to remove the ethyl acetate to obtain 207 ml aqueous extract;

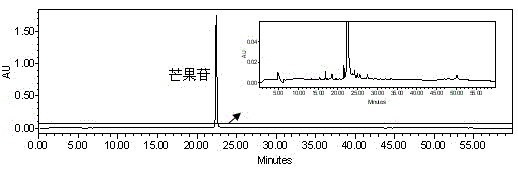

[0046] (3) 207 ml (0.25 mg / ml mangiferin) was injected into HPD100 macroporous resin (20 ml) at a flow rate of 2 ml / m...

Embodiment 3

[0049] The operation method of separating and purifying mangiferin of the present invention is carried out according to the following steps:

[0050] see figure 1 , (1) Weigh 10 g of 'Liuxiangmang' mango skin, add 200 ml of petroleum ether to soak for 2 h, ultrasonicate for 30 min, filter to remove the petroleum ether layer, and add 200 ml of extract (methanol : ethanol: acetone 1:1:1, v / v / v), sonicate for 30 min, filter to get the supernatant, add 200 ml extract solution to the filter residue, sonicate for 30 min, filter, combine the two supernatants, and evaporate at 45°C To the extract, dissolve the extract in double distilled water to obtain 235 ml crude extract;

[0051] (2) 235 ml (0.15 mg / ml mangiferin) crude extract, extracted twice with equal volume of ethyl acetate, concentrated the ethyl acetate phase and then extracted once with water, combined the lower phases with rotary evaporation at 45°C to remove the ethyl acetate to obtain 188 ml aqueous extract;

[0052...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com