Nickel-chromium alloy aluminum-water distributor with upper and lower fastening rings

A nickel-chromium alloy and distributor technology, applied in the metallurgical field, can solve the problems of economic loss, waste of manpower, material resources, etc., and achieve the effects of not easy to crack, good mechanical properties and weldability, and good high temperature oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

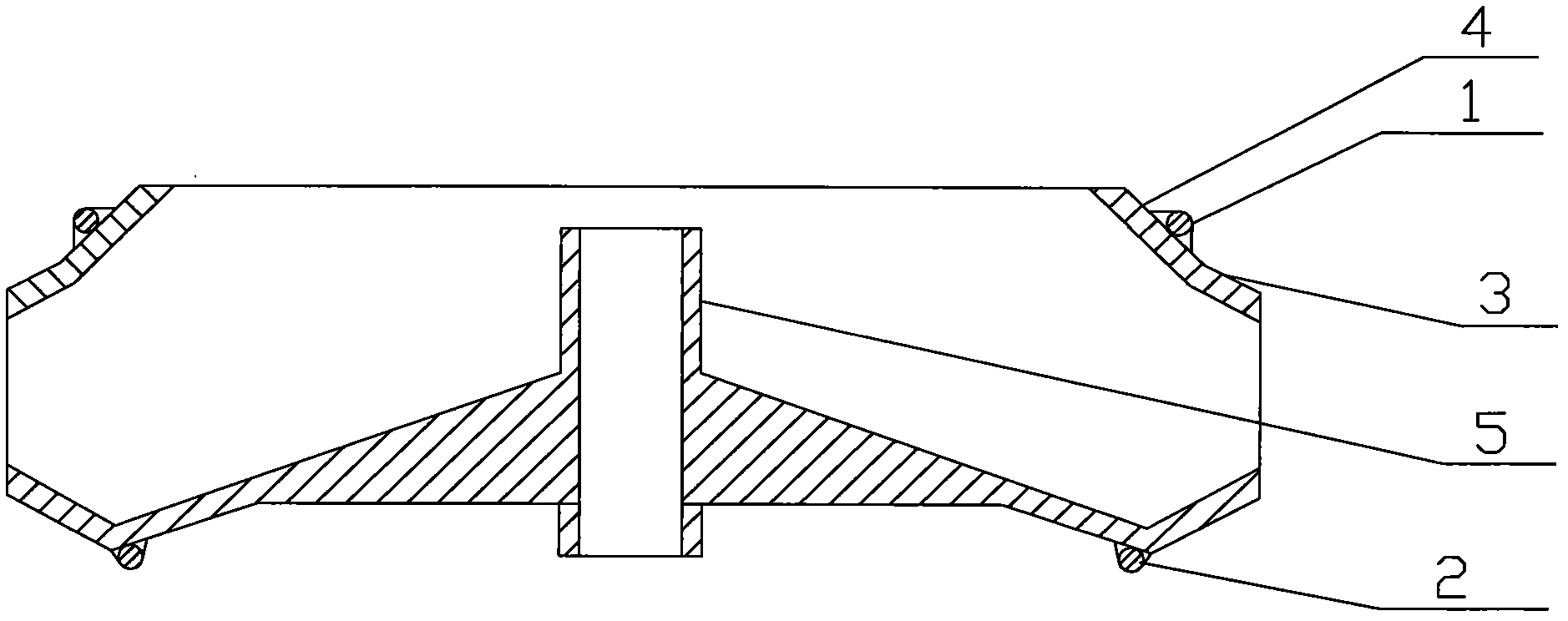

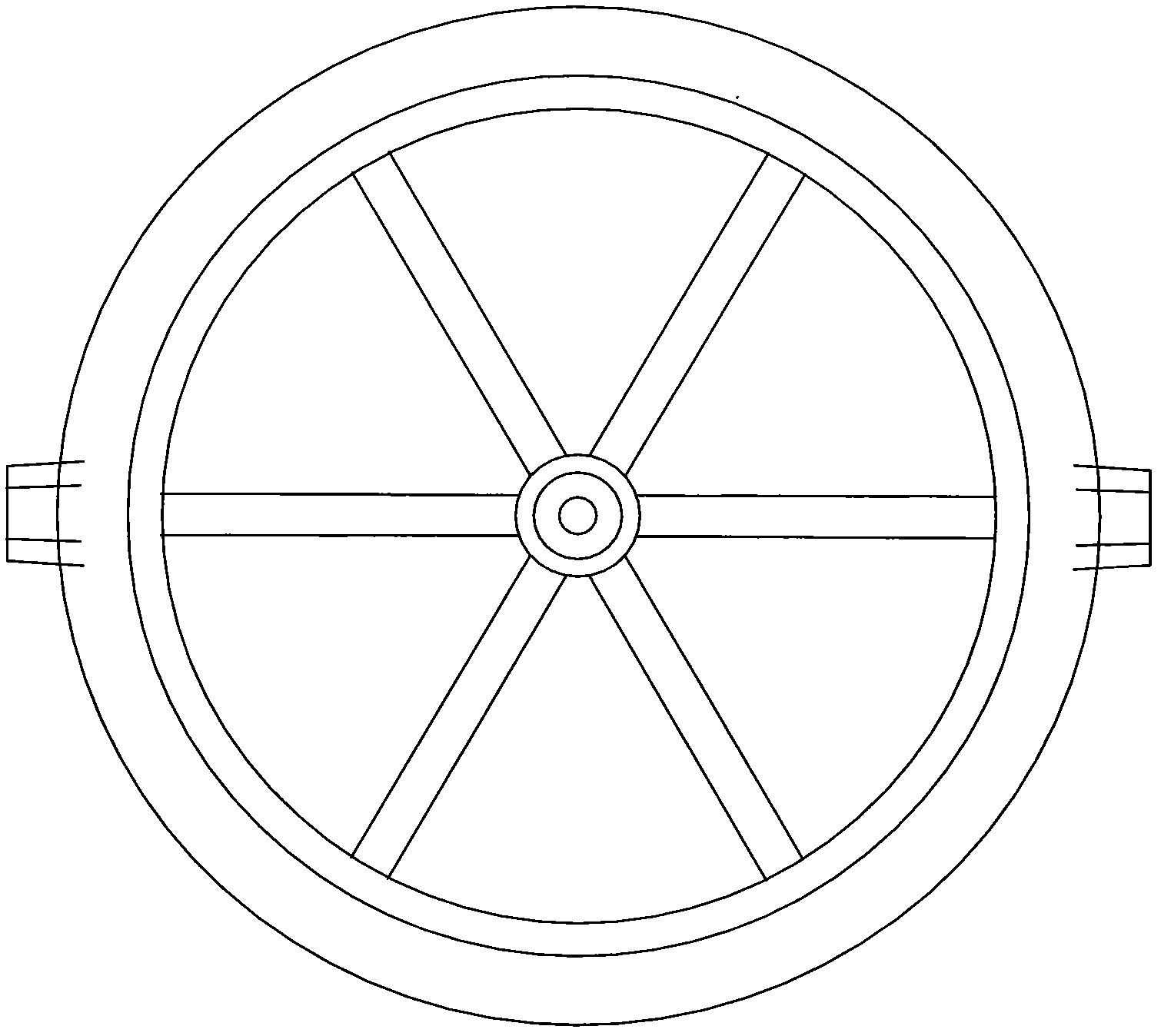

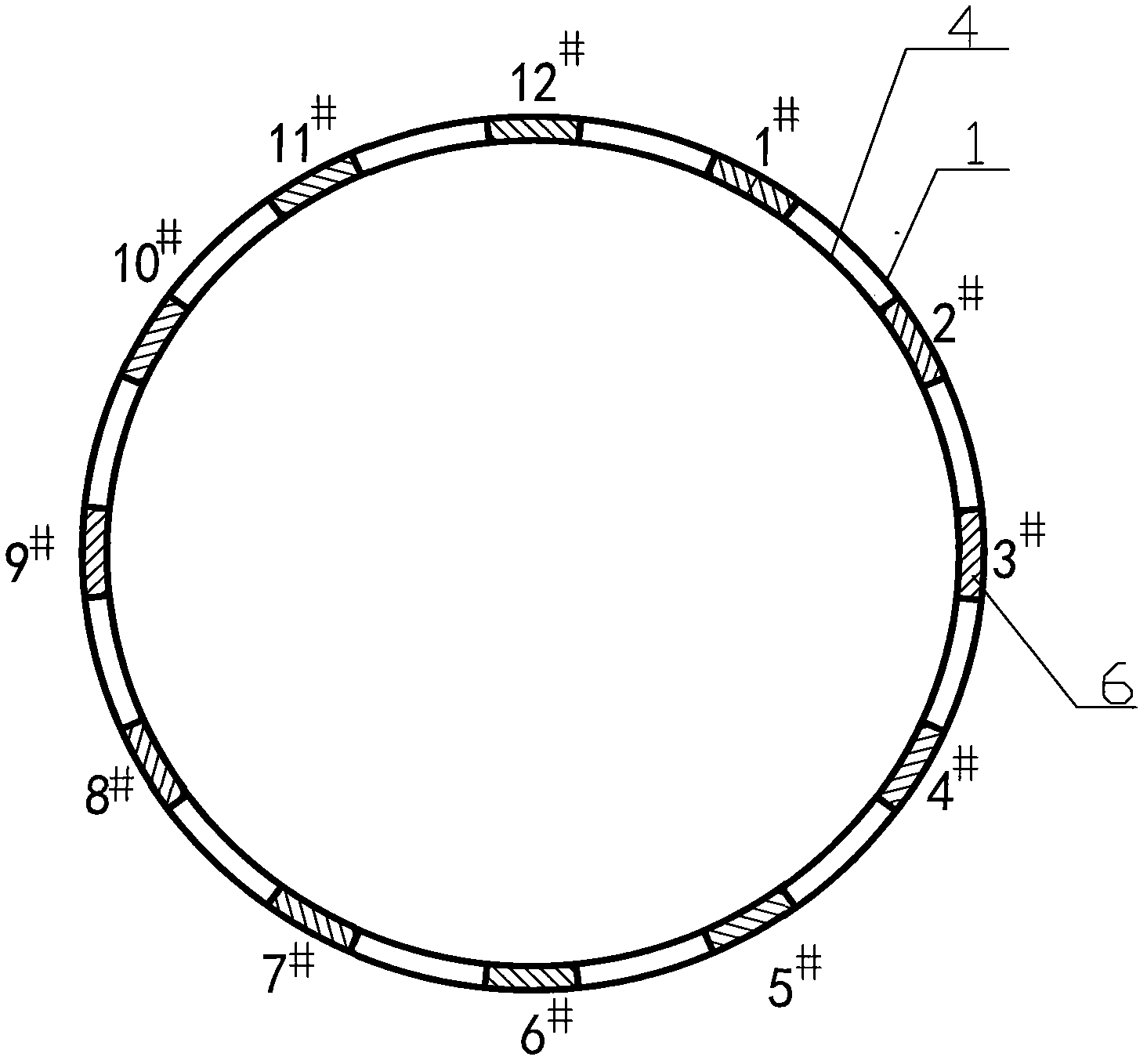

[0027] Refer to attached figure 1 , 2 , the nickel-chromium alloy aluminum water distributor with upper and lower reinforcing rings of the present invention has the same shape and body structure as the existing aluminum water distributor, including a distributor body 4, and the distributor body is surrounded by aluminum nozzles 3 at equal intervals on the circumference, A distributor bushing 5 is arranged in the middle of the distributor body, and an upper reinforcement ring 1 and a lower reinforcement ring 2 are respectively assembled and welded around the distributor body at the upper and lower parts of the aluminum nozzle of the distributor body.

[0028] The manufacturing process adopted: model making—paint preparation—hanging sand—packing—melting and pouring—welding reinforcement rings.

[0029] 1. Make a model: use polystyrene (EPS). According to the blueprint of the aluminum water distributor, it is molded with a molding machine, and the shrinkage of the model is 2%. ...

Embodiment 2

[0042]Manufacturing process is the same as embodiment 1, 450Kg charge proportioning is: carbon content is 0.15wt% high-quality low-carbon steel: 172Kg, FeCr58C0.21 ferrochrome add-on is 209Kg, FeCr58C7.5 ferrochrome add-on is 11Kg. 28Kg of nickel is added in the form of pure nickel, 6.5Kg of FeMo70 ferromolybdenum, 5.5Kg of FeNb60 ferro-niobium, 9.5Kg of FeTi30 ferro-titanium, 3Kg of FeSi60 ferrosilicon, and 5.5Kg of FeMn65 ferromanganese.

[0043] Laboratory analysis: chemical composition (weight percent): C: 0.35, Cr: 27, NT: 6, Mo: 1, Nb: 0.7, Ti: 0.6, Si: 0.4, Mn: 0.7, the balance is Fe and unavoidable Impurities.

[0044] The assembly welding of the stainless steel round steel reinforcement ring is the same as in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap