Method for producing copper indium gallium diselenide (CIGS) solar battery absorption layer through evaporation method

A solar cell, copper indium gallium selenide technology, applied in the direction of vacuum evaporation plating, coating, circuit, etc., can solve the problems of increasing the complexity of the process, affecting the purity of raw materials, and high equipment requirements, and avoiding large differences in evaporation temperature. The effect of reducing impurity pollution and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing an absorption layer of a copper indium gallium selenide solar cell by an evaporation method, comprising the steps of:

[0034] (1) Cuprous selenide powder, indium selenide powder and gallium selenide powder with a particle size not greater than 75 μm are Cu 2 Se 28.7%, Ga 2 Se 3 20.3%, In 2 Se 3 The ratio of 51.0% is mixed evenly, and placed at the evaporation source in the vacuum coating machine;

[0035] (2) When the vacuum degree is greater than 3×10 -3 Under the condition of Pa, heat the substrate, the substrate is molybdenum-coated soda-lime glass, and make the temperature of the substrate reach 200°C, then, the evaporation source is heated up to 1200°C at a heating rate of 400°C / min, and then, 1200°C is used for mixing The powder was heated for 2 minutes, and the mixed powder was evaporated by heating and deposited on the substrate to prepare a copper indium gallium selenide thin film with a thickness of 2 μm.

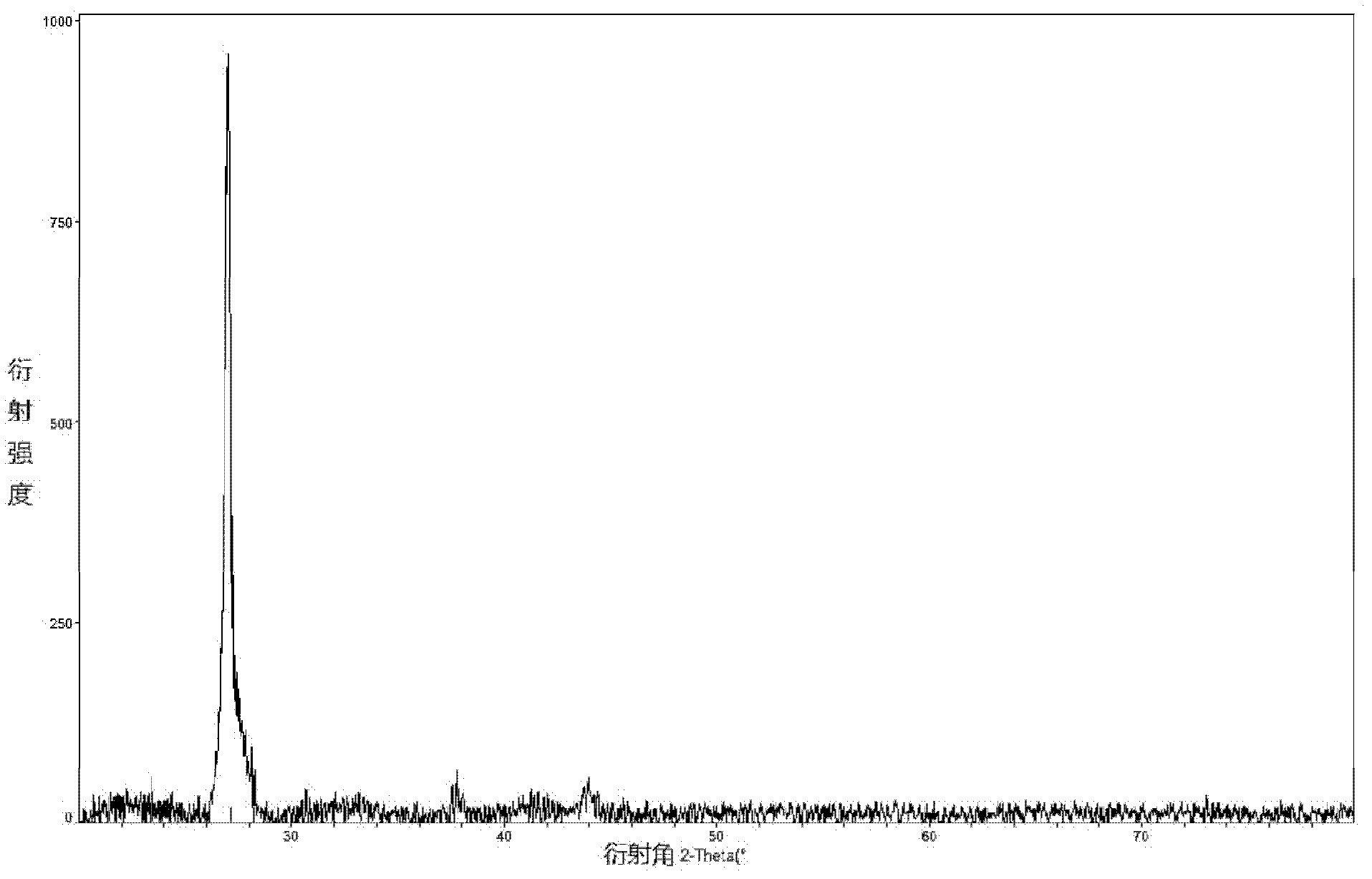

[0036] Through X-ray di...

Embodiment 2

[0038] The method for preparing the absorption layer of a copper indium gallium selenide solar cell by evaporation method as described in Example 1, the difference is that:

[0039] The mass percentage of cuprous selenide powder, indium selenide powder and gallium selenide powder is Cu 2 Se 32.1%, Ga 2 Se 3 19.3%, In 2 Se 3 48.6%.

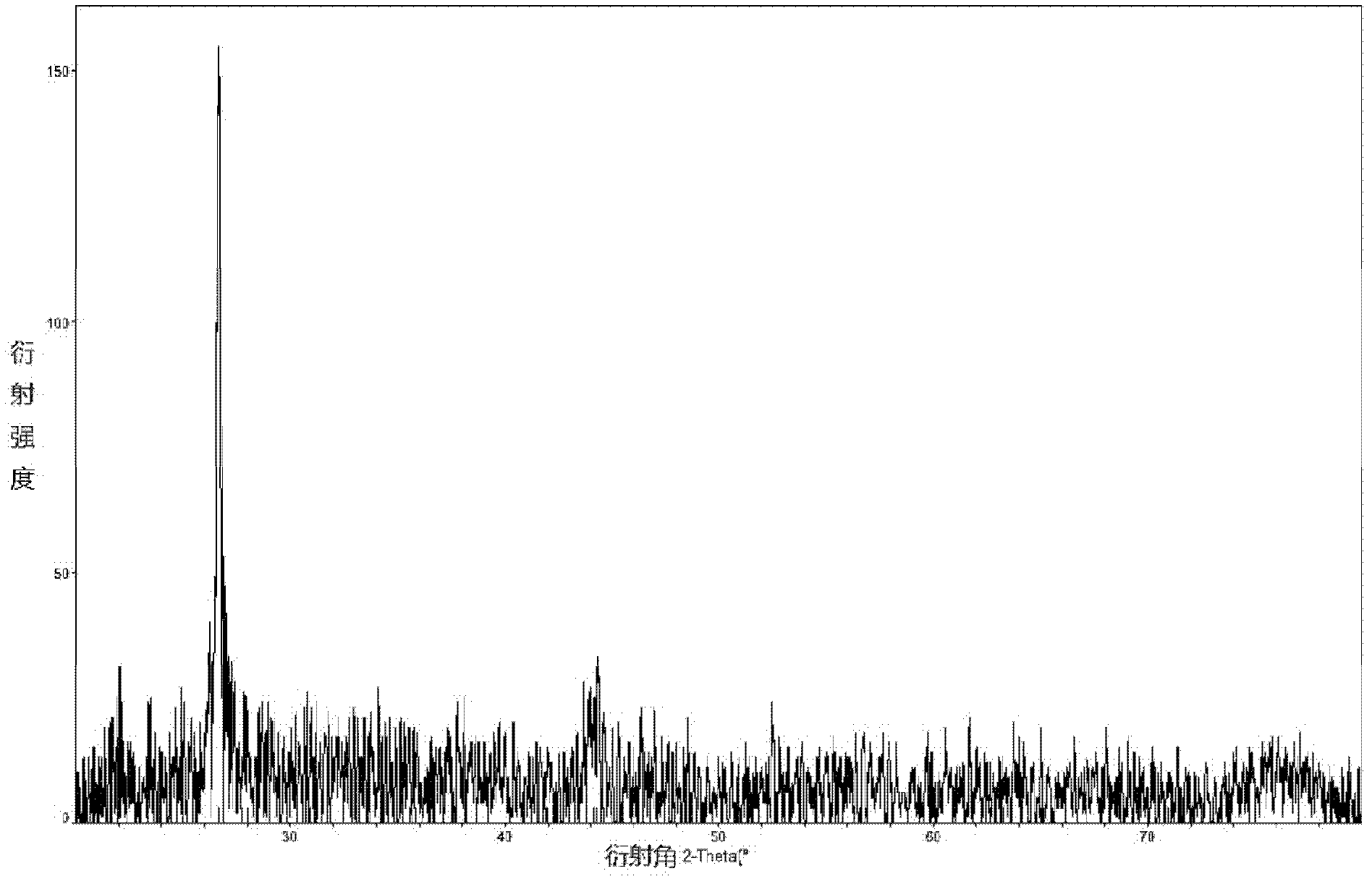

[0040] Through X-ray diffraction (XRD) analysis, the composition of the CuInGaSe thin film that makes is the CuInGaSe of the chalcopyrite structure that grows along (112) direction (such as figure 2 As shown), no impurity phase is generated, and the crystallization condition is good.

Embodiment 3

[0042] A method for preparing an absorption layer of a copper indium gallium selenide solar cell by an evaporation method, comprising the steps of:

[0043] (i) Respectively, the powder particle size is not more than 75μm 2 Se powder, In 2 Se 3 Powder and Ga 2 Se 3 Put the powder into the three evaporation sources of the three-source co-evaporation device;

[0044] (ii) In a vacuum greater than 3×10 -3 Under the condition of Pa, the substrate is heated, and the substrate is molybdenum-coated soda-lime glass, so that the temperature of the substrate reaches 150°C;

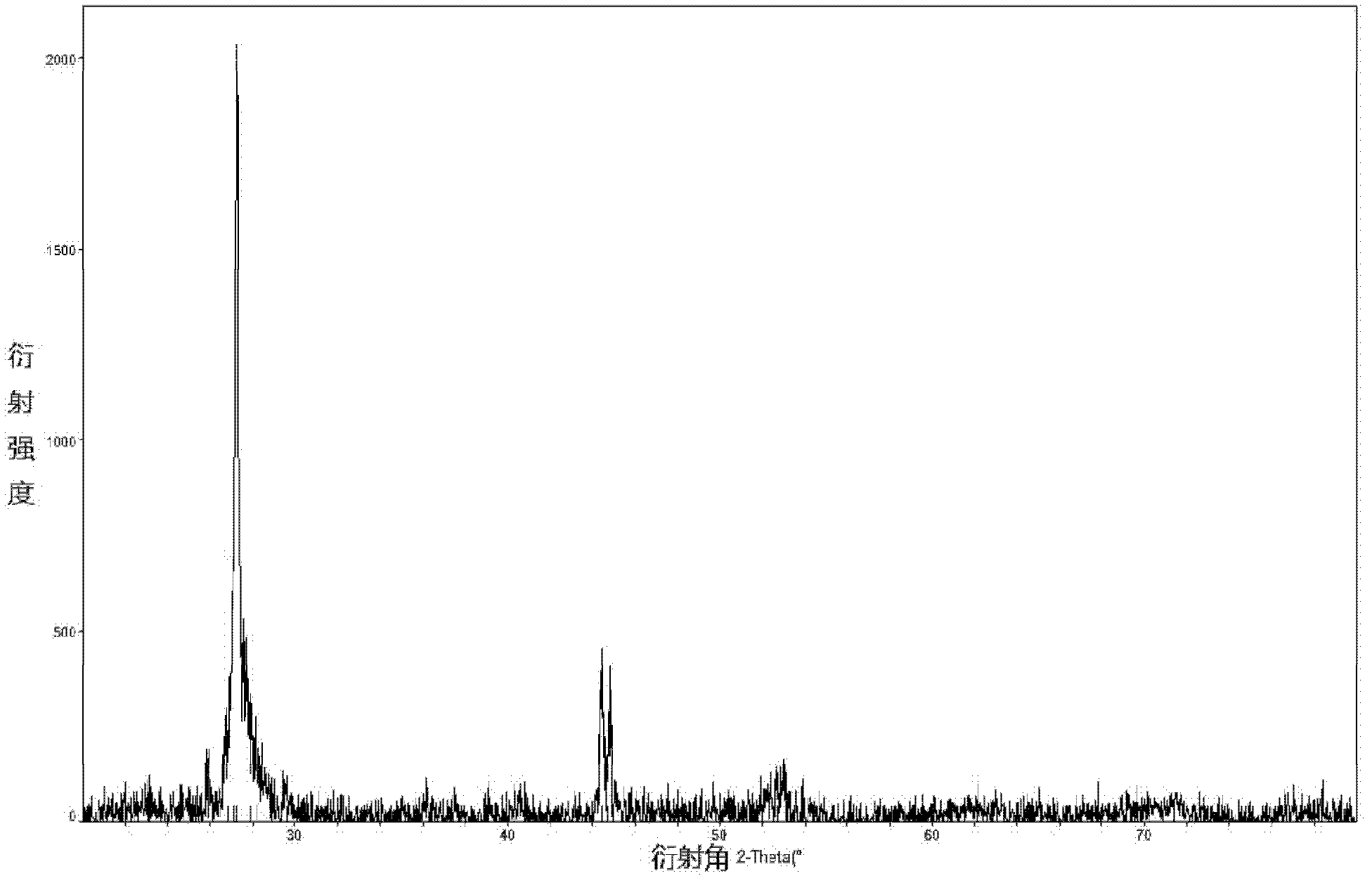

[0045] (iii) Simultaneous heating with In 2 Se 3 The evaporation source of the powder and the addition of Ga 2 Se 3 The evaporation source of the powder, at a heating rate of 400 ° C / min, so that the addition of In 2 Se 3 The temperature of the evaporation source of the powder is raised to 600°C, adding Ga 2 Se 3 The temperature of the evaporation source of the powder rises to 900 °C, In 2 Se 3 Powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com