Preparation method and purposes of photosensitivity polymer base carbon nanotube disperse auxiliary

A technology of photosensitive polymers and carbon nanotubes, applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve the problems of strict preparation conditions and cumbersome processes, achieve good solubility and dispersion performance, and easy preparation and operation , excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Get branched polystyrene maleic anhydride (BPSMA) 0.81g (maleic anhydride group 4mmol), 7-amino-4 methylcoumarin (AMC) 0.175g (1mmol) into a 100mL three-necked flask , add 18.72g of dimethyl sulfoxide, stir at about 25°C to dissolve the solid, pass nitrogen gas for 30min, seal the container and heat up to 30°C, and react at constant temperature for 72h under stirring conditions. The mixed solvent is a precipitating agent, and the reacted solution is slowly dropped into the precipitating agent, and a light yellow solid is obtained by suction filtration. The resulting solid was dissolved, precipitated, filtered, and vacuum-dried at 25°C to obtain the photosensitive polymer BPSMA-AMC.

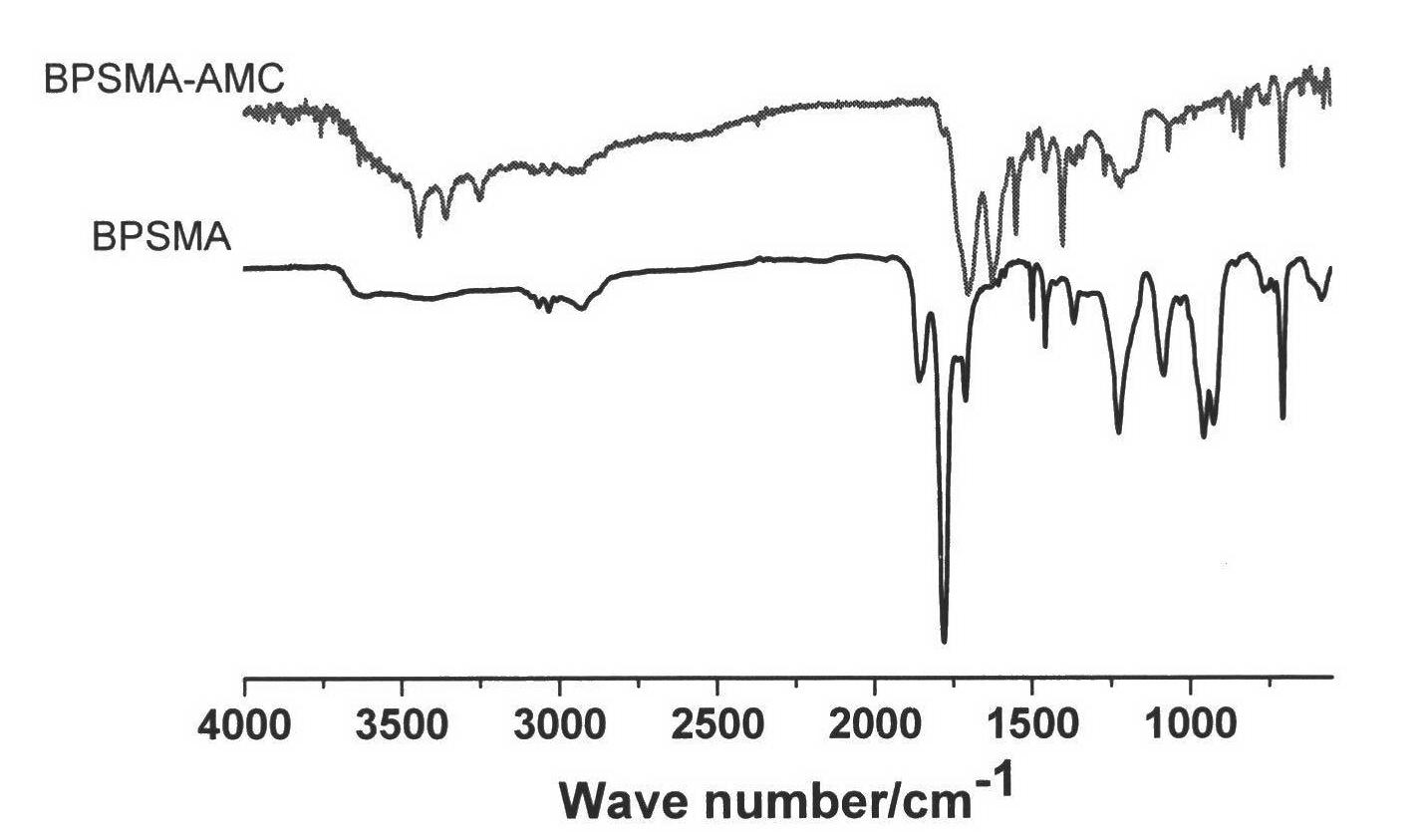

[0035]The FTIR figure of the photosensitive polymer-based carbon nanotube dispersion aid BPSMA-AMC prepared in this embodiment is shown in figure 1 .

Embodiment 2

[0037] Take polystyrene maleic anhydride (APSMA) 0.81g (maleic anhydride group 4mmol) and 7-amino-4 methylcoumarin (AMC) 0.35g (2mmol) of alternating structure into a 100mL three-necked flask, Add 16.24g of dimethyl sulfoxide, stir at room temperature to dissolve the solid, and pass nitrogen gas for 45min. After sealing the container, heat up to 35°C. Precipitating agent, slowly drop the reacted solution into the precipitating agent, and filter with suction to obtain a light yellow solid. The resulting solid was dissolved, precipitated, filtered, and vacuum-dried at 25°C to obtain the photosensitive polymer APSMA-AMC.

Embodiment 3

[0039] Take polystyrene maleic anhydride (PSMA) 0.81g (maleic anhydride group 4mmol) and 7-amino-4 methylcoumarin (AMC) 0.525g (4mmol)g of random structure into a 100mL three-necked flask Add 12g of dimethyl sulfoxide, stir at room temperature to dissolve the solid, and pass nitrogen gas for 60min. After sealing the container, heat up to 40°C. As a precipitating agent, the reacted solution was slowly dropped into the precipitating agent, and a light yellow solid was obtained by suction filtration. The resulting solid was dissolved, precipitated, filtered, and vacuum-dried at 25°C to obtain the photosensitive polymer PSMA-AMC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com