Manufacture method of dye sensitized solar battery based on gallium nitride (GaN) nanometer post structure

A solar cell and dye sensitization technology, applied in the field of microelectronics, can solve the problems of low electron mobility, low area, and low photoelectric conversion efficiency, and achieve the effects of stable chemical properties, high transmittance, and improved photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

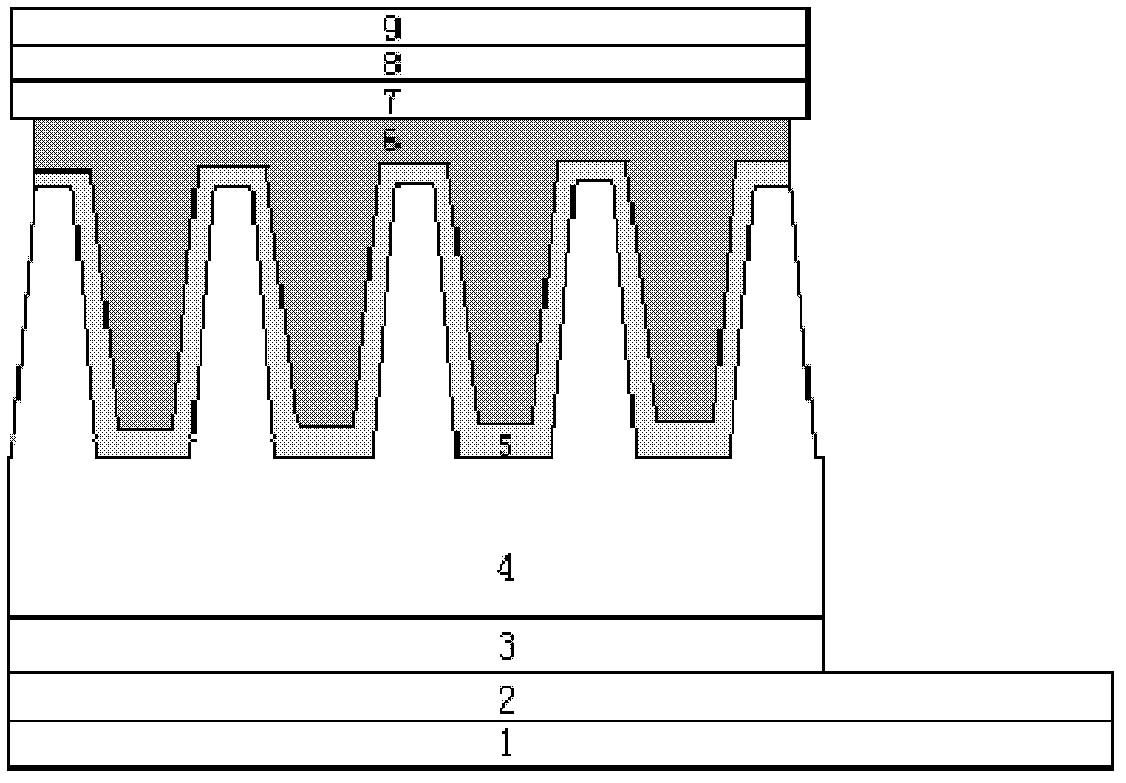

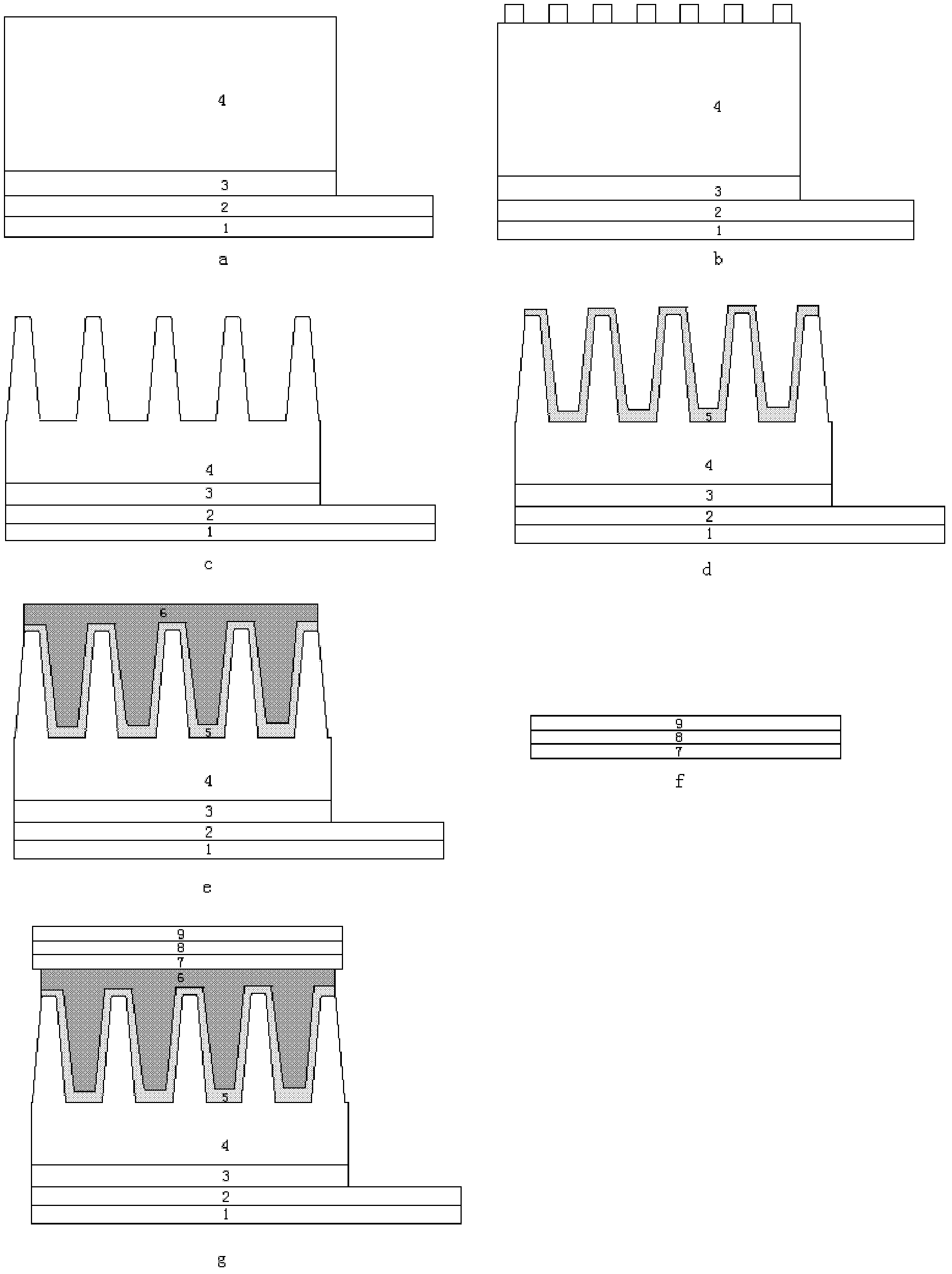

[0030] Example 1: Fabrication of a GaN nanocolumn dye-sensitized solar cell with a nanocolumn height of 600nm and a pitch of 450nm:

[0031] Step 1, using the ECR-PEMOCVD method to grow n-GaN layer on the indium tin oxide ITO conductive substrate, such as figure 2 a:

[0032] 1.1) Using hydrogen as the carrier gas and using high-purity nitrogen as the nitrogen source to grow a GaN buffer layer with a thickness of 60 nm on the indium tin oxide ITO, the growth process conditions are: nitrogen flow rate is 70 sccm, trimethylgallium flow rate is 0.4 sccm, The input microwave power is 550W, and the reaction temperature is 150°C;

[0033] 1.2) Keep the gas flow rate, gas composition and microwave power constant, raise the substrate temperature to 350°C, and grow an n-GaN layer on the GaN buffer layer. The n-GaN layer has a thickness of 1 μm and a carrier concentration of 1 ×10 17 cm -3 .

[0034] Step 2, put the indium tin oxide ITO conductive substrate grown with n-GaN into a...

Embodiment 2

[0049] Example 2: Fabrication of a GaN nanocolumn dye-sensitized solar cell with a nanocolumn height of 650nm and a pitch of 400nm:

[0050] Step 1, using the ECR-PEMOCVD method to grow n-GaN layer on the indium tin oxide ITO conductive substrate, such as figure 2 a.

[0051] First, using hydrogen as the carrier gas and high-purity nitrogen as the nitrogen source, the flow rate of nitrogen gas is 80 sccm, the flow rate of trimethylgallium is 0.5 sccm, the input microwave power is 600W, and the reaction temperature is 200°C. A GaN buffer layer with a thickness of 65nm is grown on tin ITO;

[0052] Then, keeping the gas flow rate, gas composition and microwave power constant, the substrate temperature was increased to 400°C, and the GaN buffer layer was grown with a thickness of 1.5 μm and a carrier concentration of 4×10 17 cm -3 n-GaN layer.

[0053] Step 2: Place the indium tin oxide ITO conductive substrate grown with n-GaN into acetone and absolute ethanol in sequence f...

Embodiment 3

[0066] Example 3: Fabrication of a GaN nanocolumn dye-sensitized solar cell with a nanocolumn height of 750nm and a pitch of 350nm:

[0067] Step A, using the ECR-PEMOCVD method to grow n-GaN layer on the indium tin oxide ITO conductive substrate, that is, first use hydrogen as the carrier gas, use high-purity nitrogen as the nitrogen source, and use the nitrogen flow rate at 75 sccm, trimethylgallium The flow rate is 0.6sccm, the input microwave power is 650W, and the reaction temperature is 185°C, a GaN buffer layer with a thickness of 70nm is grown on the indium tin oxide ITO; The bottom temperature rises to 380 °C, the thickness of the GaN buffer layer is 2 μm, and the carrier concentration is 1×10 18 cm -3 n-GaN layer, such as figure 2 a.

[0068] In step B, put the indium tin oxide ITO conductive substrate grown with n-GaN into acetone for 3 minutes for ultrasonic cleaning, then put it into absolute ethanol for 3 minutes, and finally rinse with deionized water for 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com