Method for producing edible fungi flavoring powder

A production method and seasoning powder technology, applied in the field of new biological products, can solve problems such as blackening, troublesome preservation and transportation of quick-frozen products, inconvenient use, etc., and achieve the effect of strong fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

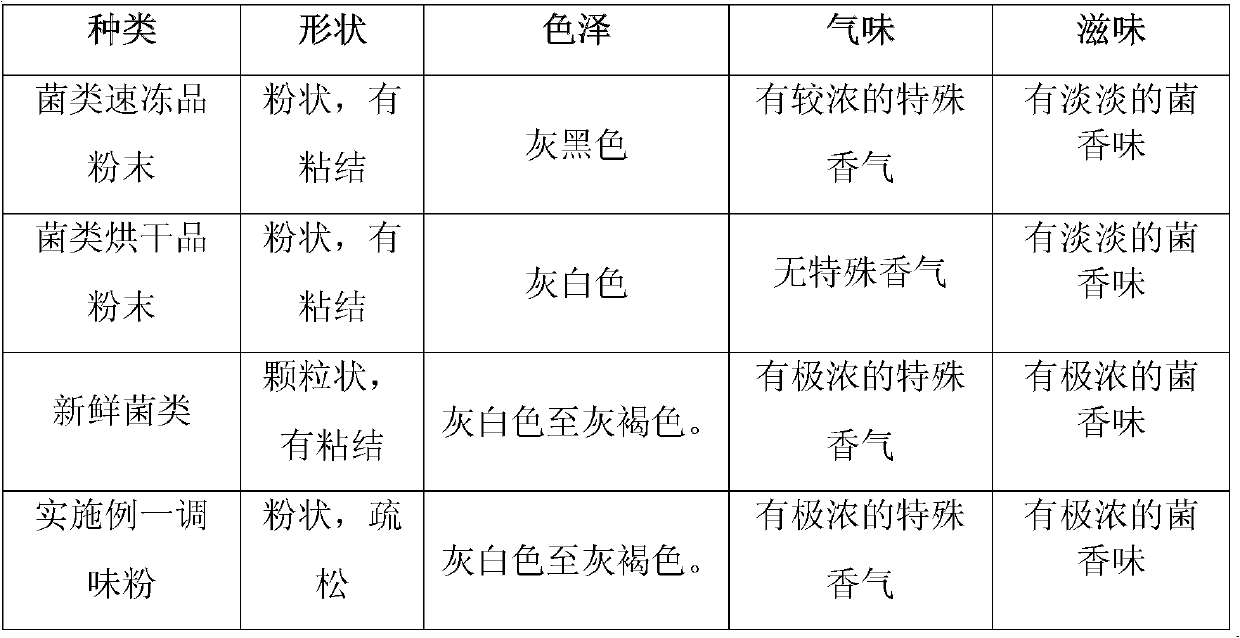

Examples

Embodiment 1

[0050] A. Raw material preparation: collect truffle, matsutake, morel, boletus, and black tiger palm 5 kinds of wild fresh edible fungi, wash, cut into thin slices, and put them in edible ethanol containing 0.2% citric acid and 0.04% TBHQ Soak for 1min, and dry the surface moisture at 5°C.

[0051] B. Freeze-drying: put the raw material processed in step A into a vacuum freeze dryer for freezing, the freezing speed is 1°C / min, the final freezing temperature is -30°C, and keep warm for 1h. Vacuum the dryer to 40Pa, control the drying temperature at -20°C, and dry for 4 hours. Then the drying temperature was raised to 40° C. (heating rate 1° C. / min), the vacuum pressure was gradually reduced to 8 Pa, and the drying time was 10 minutes to obtain freeze-dried sheets of five kinds of fungi.

[0052] C. Crushing and sieving: crush the freeze-dried sheets of various fungi dried in step B, and pass through a 100-mesh sieve to obtain freeze-dried powders of various fungi.

[0053] D....

Embodiment 2

[0061] A. Raw material preparation: collect truffles, Hericium erinaceus, chanterelles, shiitake mushrooms, and Pleurotus eryngii 5 kinds of fresh edible fungi, wash them, cut them into thin slices, and soak them in edible ethanol containing 0.3% citric acid and 0.08% TBHQ 2min, dry the surface moisture at 8°C.

[0062] B. Freeze-drying: put the raw materials processed in step A into a vacuum freeze dryer for freezing, the freezing speed is 2°C / min, the final freezing temperature is -25°C, and the temperature is kept for 2 hours. Vacuum the dryer to 40Pa, control the drying temperature at -25°C, and dry for about 3 hours. Then the drying temperature was raised to 45° C. (heating rate 2° C. / min), the vacuum pressure was gradually reduced to 10 Pa, and the drying time was 10 minutes to obtain freeze-dried sheets of various fungi.

[0063] C. Crushing and sieving: crush the freeze-dried sheets of various fungi dried in B, and pass through a 100-mesh sieve to obtain freeze-dried ...

Embodiment 3

[0072] A. Raw material preparation: collect truffles, pine milk mushrooms, jitake mushrooms, collybia mushrooms, tea tree mushrooms, and russula 6 kinds of fresh edible fungi, wash them, cut them into thin slices, and put them in the 0.2% citric acid and 0.03% TBHQ Soak in edible ethanol for 2 minutes, and dry the surface moisture at 5°C.

[0073] B. Freeze-drying: put the raw material processed in step A into a vacuum freeze dryer for freezing, the freezing speed is 1°C / min, the final freezing temperature is -30°C, and the temperature is kept for 2 hours. Vacuum the dryer to 35Pa, control the drying temperature at -23°C, and dry for about 4 hours. Then the drying temperature was raised to 40° C. (heating rate 2° C. / min), the vacuum pressure was gradually reduced to 8 Pa, and the drying time was 10 minutes to obtain freeze-dried sheets of various fungi.

[0074] C. Crushing and sieving: crush the freeze-dried sheets of various fungi dried in step B, and pass through a 100-mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com