Anisotropic wurtzite MnSe nanocrystal synthesized by utilizing solvothermal method

A wurtzite and anisotropic technology, which is applied in the field of preparing anisotropic wurtzite MnSe nanocrystals, can solve the problems of uncontrollable, impure nanocrystalline crystal structure, irregular shape, etc., and achieve repeatability Effects with high height, controllable shape and aspect ratio, and short synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

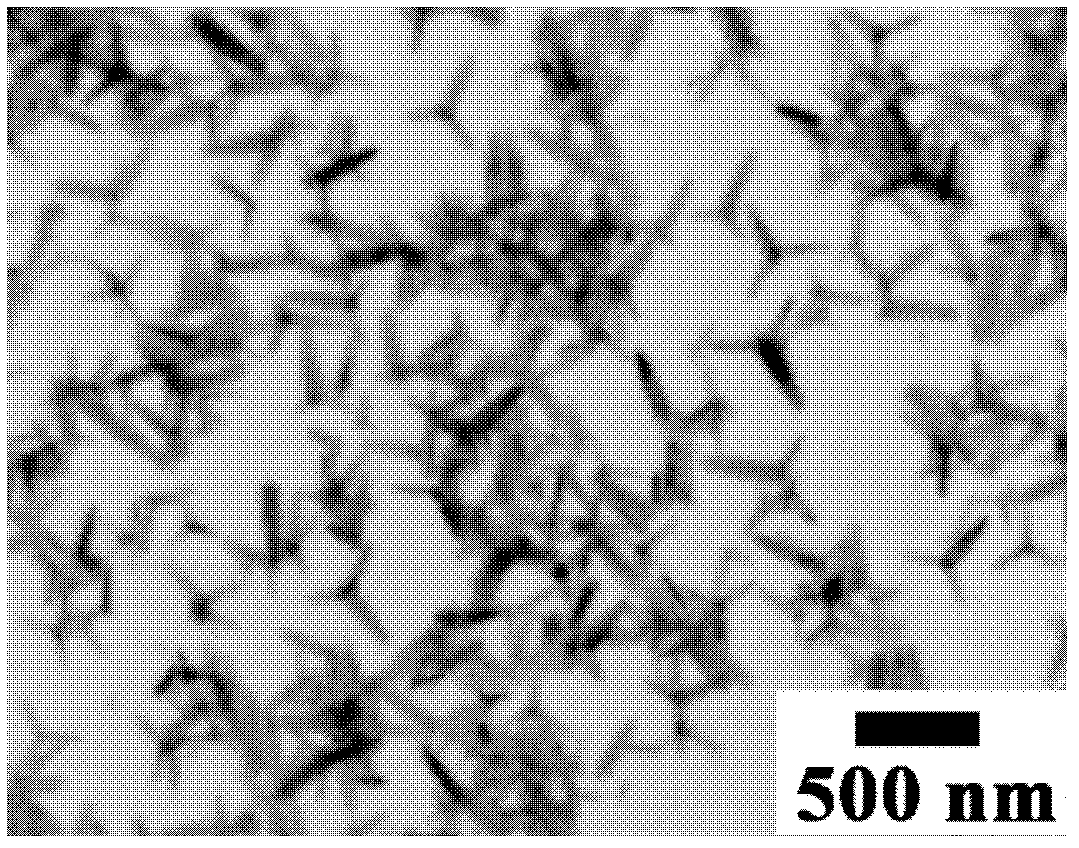

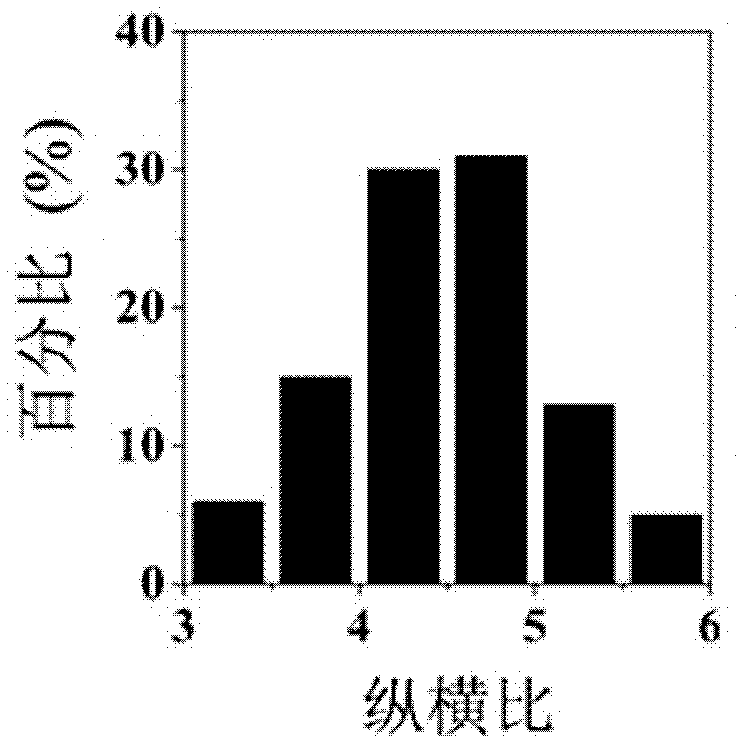

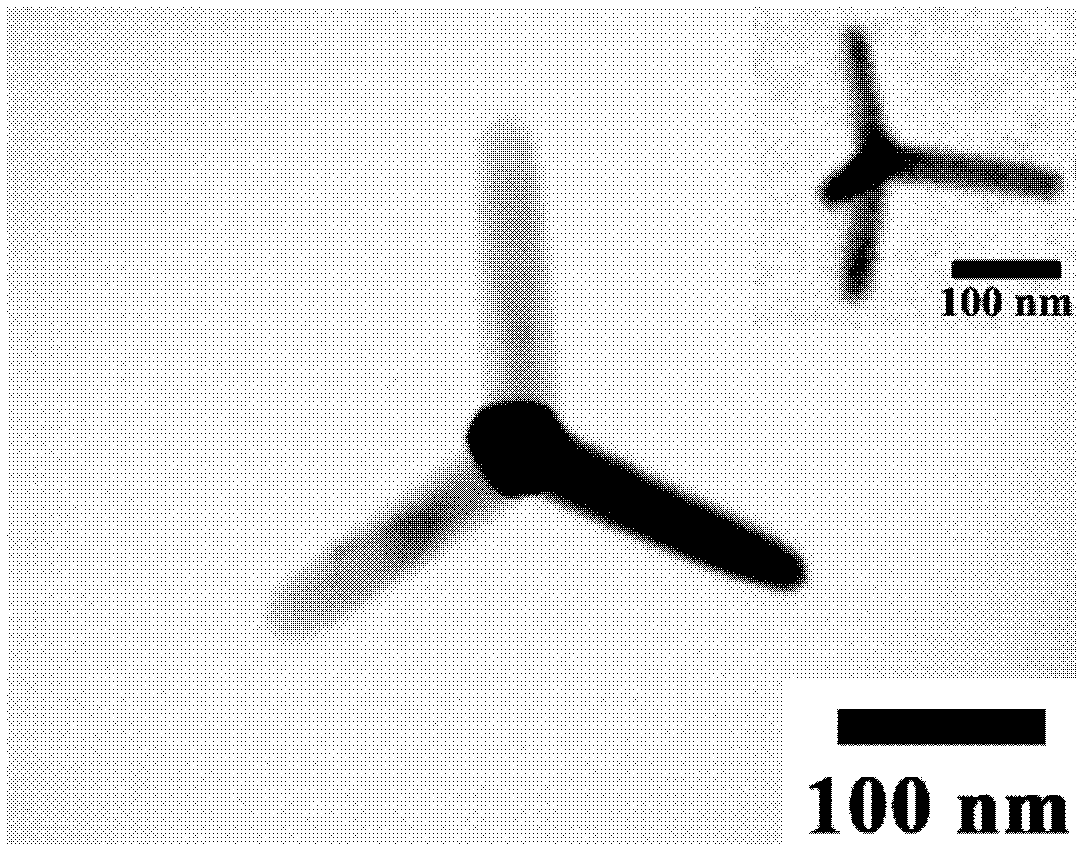

[0031] Example 1 Synthesis of Anisotropic Wurtzite MnSe Nanocrystals

[0032] The synthesis of anisotropic wurtzite MnSe nanocrystals is carried out in a Schlenk system, and the synthesis process requires nitrogen protection. The specific synthesis process is as follows: 0.032g of anhydrous MnCl 2 , 0.02g Se powder, 4mL oleic acid and 4mL oleylamine were put into a three-necked flask, then the two sides of the three-necked flask were plugged with rubber stoppers, the middle port was connected to the Schlenk system, and the thermocouple was connected from the three-necked flask to the Schlenk system. One side was inserted under the liquid surface, stirred and heated to 200 °C, and a pale yellow clear solution was obtained after about 4 hours. The solution was heated to 300°C at a heating rate of 2°C / min, and the transparent pale yellow solution gradually became turbid, that is, anisotropic wurtzite MnSe nanocrystals were formed, and the sample was extracted after 30 minutes.

...

Embodiment 2

[0034] Example 2 Synthesis of Anisotropic Wurtzite MnSe Nanocrystals

[0035] The synthesis of anisotropic wurtzite MnSe nanocrystals is carried out in a Schlenk system, and the synthesis process requires nitrogen protection. The specific synthesis process is as follows: 0.032g of anhydrous MnCl 2 , 0.02g Se powder, 4mL oleic acid and 4mL oleylamine were put into a three-necked flask, then the two sides of the three-necked flask were plugged with rubber stoppers, the middle port was connected to the Schlenk system, and the thermocouple was connected from the three-necked flask to the Schlenk system. One side was inserted under the liquid surface, stirred and heated to 200 °C, and a pale yellow clear solution was obtained after about 4 hours. The solution was heated to 300°C at a heating rate of 15°C / min, and the transparent pale yellow solution gradually became turbid, that is, anisotropic wurtzite MnSe nanocrystals were formed, and the sample was extracted after 30 minutes. ...

Embodiment 3

[0037] Example 3 Synthesis of Anisotropic Wurtzite MnSe Nanocrystals

[0038] The synthesis of anisotropic wurtzite MnSe nanocrystals is carried out in a Schlenk system, and the synthesis process requires nitrogen protection. The specific synthesis process is as follows: 0.032g of anhydrous MnCl 2, 0.02g Se powder, 4mL oleic acid and 4mL oleylamine were put into a three-necked flask, then the two sides of the three-necked flask were plugged with rubber stoppers, the middle port was connected to the Schlenk system, and the thermocouple was connected from the three-necked flask to the Schlenk system. One side was inserted under the liquid surface, stirred and heated to 200 °C, and a pale yellow clear solution was obtained after about 4 hours. The solution was heated to 300°C at a heating rate of 25°C / min, and the transparent pale yellow solution gradually became turbid, that is, anisotropic wurtzite MnSe nanocrystals were formed, and the sample was extracted after 30 minutes.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com