Hydrothermal preparation method for NiS2 with controllable shape

A morphological and hydrothermal technology, applied in nickel sulfide, nanotechnology and other directions, can solve the problems of high production cost, flammable, explosive, and volatile, and achieve low production cost, low human toxicity, and narrow particle size distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of NiS with different shapes and particle sizes by hydrothermal method 2 method, the steps are as follows:

[0035] Press Ni 2+ / S 2 o 3 2- =1 (molar ratio), weigh a certain amount of NiCl 2 ?6H 2 O and Na 2 S 2 o 3 ?5H 2 O, moved to a 100ml Teflon-lined autoclave. Then add distilled water to fill up to 80% of the total capacity of the reactor, place it on a magnetic stirrer and stir for 10 minutes to fully dissolve the solid. Then the reaction vessel was sealed and allowed to react at a constant temperature of 140°C for 12h. After the reaction kettle was naturally cooled to room temperature, the obtained product was washed several times with distilled water and ethanol, separated by centrifugation, and dried at 60°C to obtain a black product.

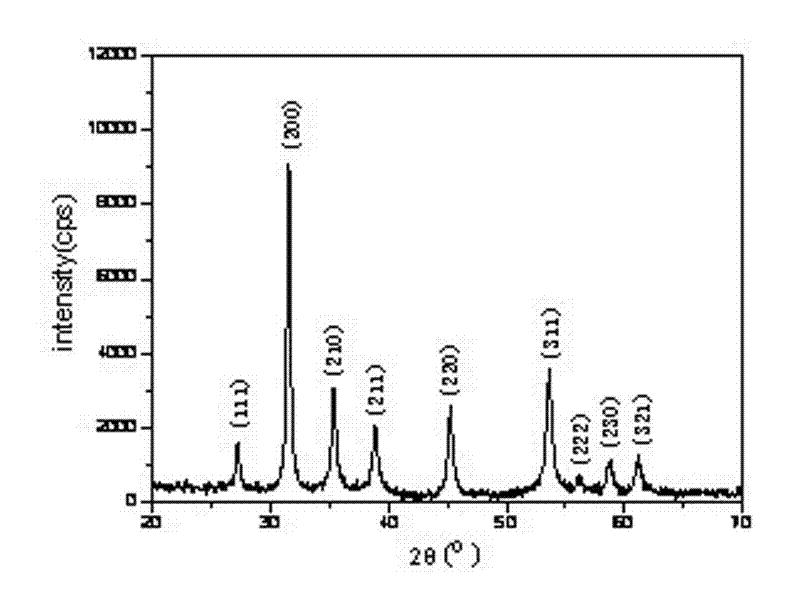

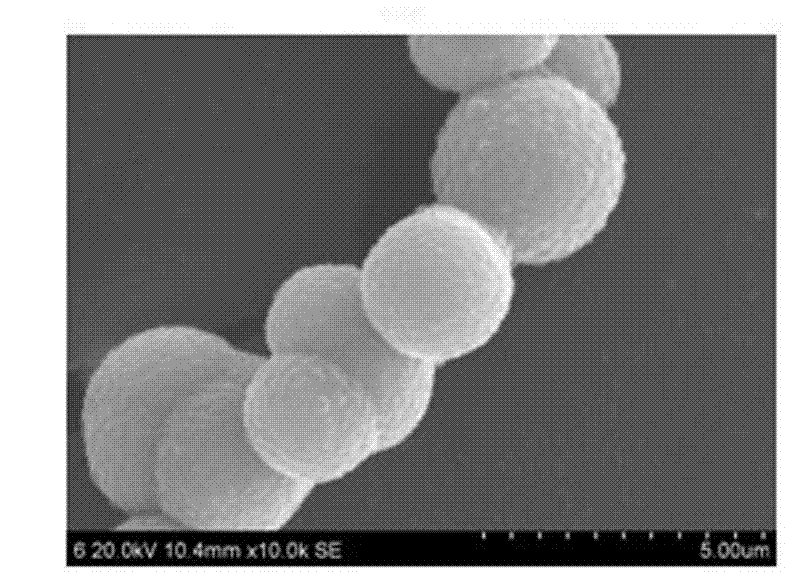

[0036] attached figure 1 and 2 XRD pattern and SEM pattern of the product, respectively. Both illustrate that the above-mentioned preparation product is NiS 2 , and its shape is spherical, which is re...

Embodiment 2

[0038] Preparation of NiS with different shapes and particle sizes by hydrothermal method 2 method, the steps are as follows

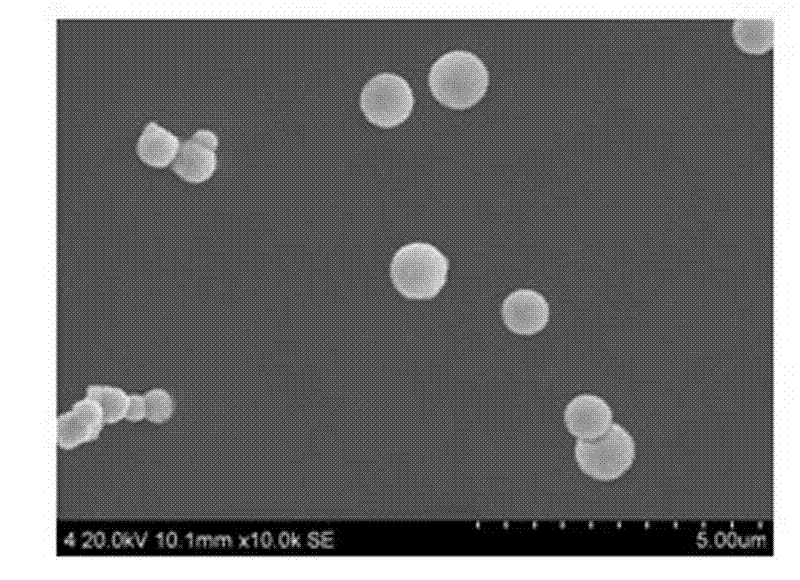

[0039] Prepare NiS by the step of embodiment 1 2 , The different reaction conditions are: the reaction time is 6h and 24h respectively. attached image 3 and 4 The SEM pictures of the two products are respectively, they show that the product NiS 2 The morphologies of both are spherical, indicating smoothness, but the particle diameters of the two are different, about 1μ and 5μ respectively.

[0040] This example illustrates that NiS with a spherical shape can be prepared by adopting the technology of the present invention. 2 . In conjunction with Example 1, this example emphasizes that by changing the synthesis conditions, the product NiS 2 The particle size is adjusted.

Embodiment 3

[0042] Preparation of NiS with different shapes and particle sizes by hydrothermal method 2 method, the steps are as follows

[0043] Prepare NiS by the step of embodiment 1 2 , The different reaction conditions are: the reaction temperature is 180°C. attached Figure 5 and 6 They are the XRD pattern and SEM pattern of the product respectively, both of which indicate that the above-mentioned prepared product is NiS 2 , The particle morphology is nearly quadrilateral flake, the side length is 1~2μ, and the thickness is 300~500nm. The quadrilateral flake particles are stacked in a nearly spherical form.

[0044] This example illustrates that the technology of the present invention can be used to prepare phase-pure and nearly quadrilateral plate-like NiS 2 . Compared with Example 1, this example also illustrates that by changing the synthesis conditions, the product NiS 2 shape control.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com