Thermoplastic polyimide resin and preparation method thereof

A polyimide resin and thermoplastic technology, applied in the field of thermoplastic polyimide resin and its preparation, can solve the problems of difficult synthesis, lowering the glass transition temperature of polymers, and impossibility of large-scale application, etc., and achieve good thermal stability , the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

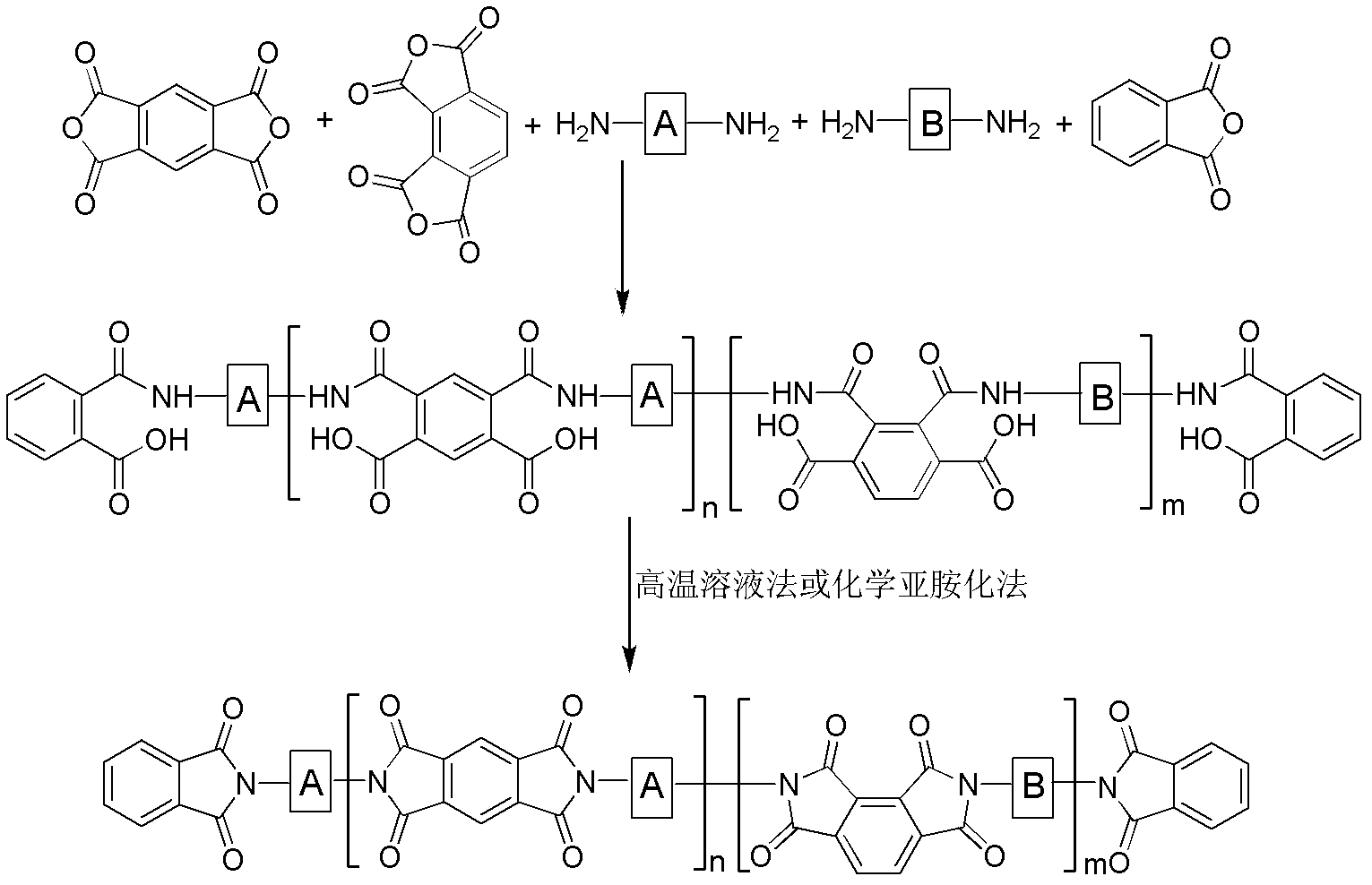

[0051] In the present embodiment, the structural formula of thermoplastic polyimide resin is:

[0052]

[0053] The preparation route of this thermoplastic polyimide resin is as follows figure 1 As shown, where A and B are groups: Concrete preparation method comprises the following steps:

[0054] Step 1: At room temperature, 2.5949 grams (0.006 moles) of 4,4'-bis(3-aminophenoxy)diphenyl sulfone and 16 milliliters of N-methylpyrrolidone were added to an agitator equipped with nitrogen protection in the reactor. After 4,4'-bis(3-aminophenoxy)diphenyl sulfone is completely dissolved, add 0.6216 grams (0.00285 moles) of 1,2,3,4-pyrellitic dianhydride, 0.6216 grams (0.00285 moles ) of pyromellitic dianhydride and 0.0889 grams (0.0006 moles) of phthalic anhydride, stirred and reacted for 2 to 24 hours to obtain a light yellow transparent viscous liquid;

[0055] Step 2: Add 8 ml of xylene to the reaction system obtained in step 1, raise the temperature to 180°C, reflux with...

Embodiment 2

[0059] In the present embodiment, the structural formula of thermoplastic polyimide resin is:

[0060]

[0061] The concrete preparation method of this thermoplastic polyimide resin comprises the steps:

[0062] Step 1: At room temperature, 2.5949 grams (0.006 moles) of 4,4'-bis(3-aminophenoxy)diphenyl sulfone and 10 milliliters of m-cresol were added to a reactor equipped with a stirrer and nitrogen protection middle. After 4,4'-bis(3-aminophenoxy)diphenyl sulfone is completely dissolved, add 0.9767 grams (0.00448 moles) of pyromellitic dianhydride, 0.3255 grams (0.00149 moles) of pyromellitic dianhydride , 0.0089 grams (0.00006 moles) of phthalic anhydride and 6 drops of isoquinoline, then the reaction system was heated to 200 ° C and reacted for 8 hours. During the reaction process, the water generated by the reaction is removed from the reaction system by a water removal device to obtain a polyimide solution.

[0063] Step 2: After the reaction system is cooled, drop...

Embodiment 3

[0066] In the present embodiment, the structural formula of thermoplastic polyimide resin is:

[0067]

[0068] The concrete preparation method of this thermoplastic polyimide resin is to comprise the steps:

[0069] Step 1: At room temperature, 2.4631 g (0.006 mol) of 2-bis[4-(4-aminophenoxy)]propane and 16 ml of N-methylpyrrolidone were added to a reaction with a stirrer and nitrogen protection device. After 2-bis[4-(4-aminophenoxy)]propane is completely dissolved, add 0.6445 grams (0.002955 moles) of 1,2,3,4-pyrellitic dianhydride, 0.6445 grams (0.002955 moles) Pyromellitic dianhydride and 0.0267 grams (0.00018 moles) of phthalic anhydride were stirred and reacted for 2 to 24 hours to obtain light yellow transparent viscous liquid;

[0070] Step 2: Add 8 ml of xylene to the reaction system obtained in step 1, raise the temperature to 180°C, reflux with water for 6 hours, and after the water in the reaction system is exhausted, raise the temperature to 185°C to continue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com