Special assistant SYNOX M4229 for beta-crystal-form random copolymerization polypropylene tube materials and application thereof

A technology of random copolymerization and polypropylene tubes, which is applied in the field of materials, can solve problems such as the complexity of the preparation process of additives, and achieve the effects of facilitating industrial production, saving production management costs, and increasing heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

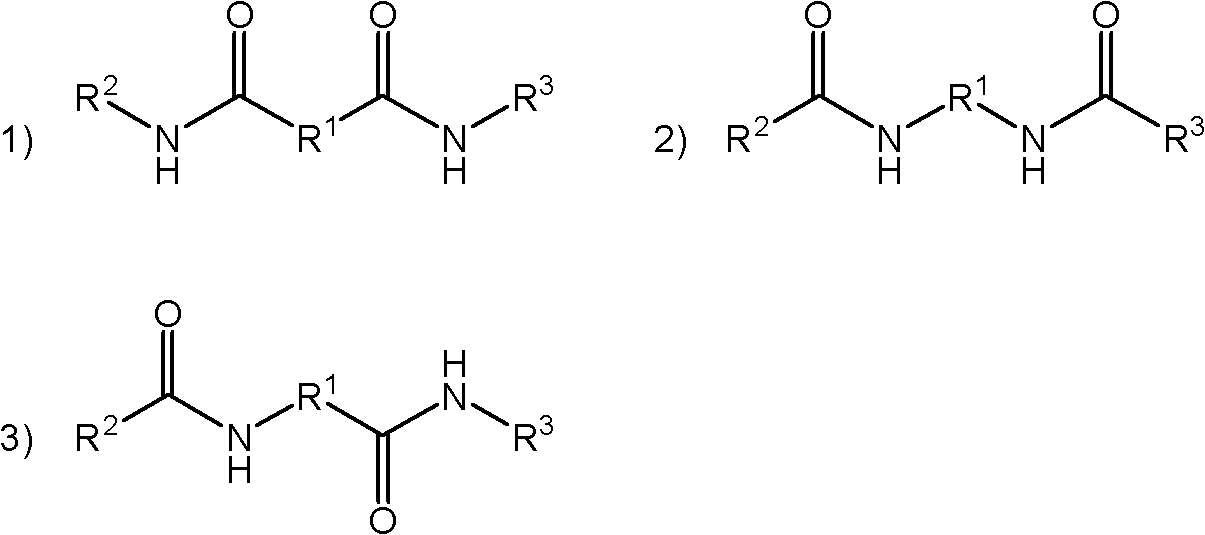

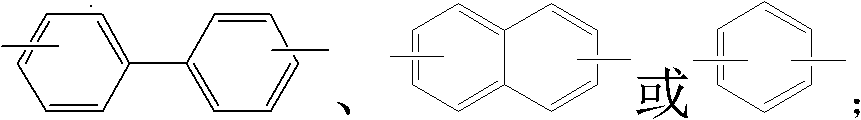

Method used

Image

Examples

Embodiment 1

[0043] 1,3,5-tris(3,5-di-tert-butyl-4-hydroxybenzyl) isocyanuric acid 35kg, bis(2,4-di-tert-butylphenol) pentaerythritol diphosphite 33kg, poly{ [6-[(1,1,3,3-tetramethylbutyl)amino]]-1,3,5-triazine-2,4-[(2,2,6,6,-tetramethyl -Piperidinyl)imino]-1,6-hexamethylene[(2,2,6,6-tetramethyl-4-piperidinyl)imino]} 2kg, calcium stearate 6kg and low molecular weight Add 4 kg of polyethylene wax to the high-speed mixer, mix and stir at room temperature for 30 minutes to obtain a mixture of anti-aging additives and processing aids; put the above mixture and 20 kg of N,N'-dicyclohexyl-2,6-naphthalene dicarboxamide into the heat After mixing and stirring for 30 minutes in the mixer, set the temperature at 120°C under the protection of nitrogen, and mix and stir the components for 30 minutes in a molten state, so that each component passes through the intermolecular hydrogen bond and the complexation of functional groups, and re The molecules of each component are arranged in space, the gate o...

Embodiment 2

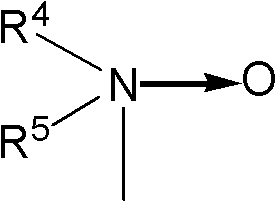

[0046] 1,3,5-trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene 24kg, dioctadecylmethylamine oxide 20kg, bis( 2,4-Di-tert-butylphenol) pentaerythritol diphosphite 30kg, synthetic hydrotalcite 7kg and glyceryl monostearate 4kg are added to the high-speed mixer, mixed and stirred at room temperature for 30 minutes to obtain a mixture of anti-aging additives and processing additives ; Put the above mixture and 15kg N,N'-dicyclohexyl-2,6-naphthalenediformamide into the hot mixer and mix and stir for 30min, and set the temperature at 120℃ under the protection of nitrogen, so that the components are in a molten state Mix and stir for 30 minutes, make each component pass the hydrogen bond between molecules and the complexation of functional groups, re-arrange the molecules of each component, open the gate of the hot mixer, and quickly remove the material system under the protection of nitrogen to cool , Use a pulverizer to crush the materials and screen them with a 200-mes...

Embodiment 3

[0049] 1,3,5-tris(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl)-1,3,5-triazine-2,4,6-(1H,3H, 5H)-Triketone 37kg, 3,9-bis(2,4-dicumylphenoxy)-2,4,8,10-tetraoxa-3,9-diphosphaspiro [5.5] eleven Alkane 15kg, bis(2,6-di-tert-butyl-4-methylphenyl) pentaerythritol diphosphate 15kg, poly{[6-[(1,1,3,3-tetramethylbutyl)amino] ]-1,3,5-Triazine-2,4-[(2,2,6,6,-tetramethyl-piperidinyl)imino]-1,6-hexanediene[(2,2 , 6,6-Tetramethyl-4-piperidinyl)imino]}5kg, zinc stearate 6kg and low molecular polyethylene wax 4kg are added to the high-speed mixer, mixed and stirred at room temperature for 30min to obtain the anti-aging additives and processing A mixture of additives; put the above mixture and 18kg of N,N'-dicyclohexyl-2,6-naphthalene dicarboxamide into a hot mixer, mix and stir for 30 minutes, and set the temperature at 140°C under the protection of nitrogen to make each group In the molten state, mix and stir for 30 minutes, make each component pass through the intermolecular hydrogen bond and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com