Ureas nucleating agent-containing polylactic acid composite and preparation method thereof

A polylactic acid and nucleating agent technology, applied in the field of polylactic acid nucleating agents, can solve problems such as insufficient nucleation effect, unenvironmental protection in the application process, instability of polylactic acid, etc., to achieve significant nucleation effect, low cost, and responsive simple and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The steps of the preparation method of the polylactic acid composition containing urea nucleating agent are as follows:

[0047] 1) React amine and isocyanate in solvent A at 10-40°C for 0.5-3 hours, the molar ratio of isocyanate to amine is 0.4-1.5; after the reaction, filter the reaction product, and use solvent B and solvent C in sequence Wash and dry the filter residue under vacuum at 60-80°C for 8-48 hours to obtain a powdered urea nucleating agent; wherein, solvent A is N,N-dimethylacetamide or N,N-dimethylformamide , the solvent consumption is 3.5-6 times of the volume of isocyanate; Solvent B is chloroform, n-hexane, carbon tetrachloride, benzene or toluene, and the solvent consumption is 5-10 times of solvent A; Solvent C is water, methanol, ethanol, propylene glycol Alcohol or isopropanol, the amount of solvent is 5-10 times that of solvent A;

[0048] 2) Add polylactic acid and 0.1-5% urea nucleating agent of the mass of polylactic acid, or polylactic acid, ...

Embodiment 1

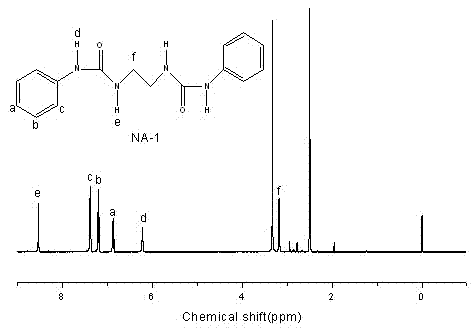

[0062] Embodiment 1: Preparation of nucleating agent NA1

[0063] Preparation process: 3.606g (60.0mmol) of ethylenediamine was dissolved in 15mL of N,N-dimethylacetamide, and 7.147g (60.0mmol, 6.54ml) of phenylisocyanate was dissolved in 15mL of N , N-dimethylacetamide dubbed solution. During the dropping process, the temperature was kept below 40°C, and after the dropping was completed, the reaction was continued for 30 minutes. After the reaction, the reactant was filtered with a Buchner funnel, and washed with 150ml (five times the volume of N,N-dimethylacetamide) chloroform and 150ml of ethanol successively, and the filter residue was vacuum-dried at 60-80°C for 8 -48 hours to constant weight, to obtain a white powder, that is, the nucleating agent NA1, with a yield of 93.1%.

[0064] The structural formula of the nucleating agent NA1 is

[0065]

[0066] The H NMR spectrum of the nucleating agent NA1 is shown in Figure 1(a).

Embodiment 2

[0067] Embodiment 2: prepare nucleating agent NA2

[0068] Preparation process: Dissolve 4.408g (50.0mmol) of butanediamine in 15mL of N,N-dimethylacetamide, and add dropwise 8.934g (75.0mmol, 8.17ml) of phenylisocyanate dissolved in 15mL of N , N-dimethylacetamide dubbed solution. During the dropwise addition, keep the temperature below 30° C., and continue the reaction for 2 hours after the dropwise addition. After the reaction, the reactant was filtered with a Buchner funnel, washed with 150ml of chloroform and 150ml of ethanol in turn, and the filter residue was vacuum-baked at 60-80°C for 8-48 hours to constant weight to obtain a white powder, that is, the nucleating agent NA2 , yield 95.4%.

[0069] The structural formula of the nucleating agent NA2 is

[0070]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com