Method for hydrolyzing straw by continuous reaction of ultra-low acid

A chemical reaction, ultra-low acid technology, applied in the field of using ultra-low acid continuous reaction to hydrolyze straw, can solve the problems of catalyst consumption inhibition, short reducing sugar residence time, low production efficiency, etc., and achieve short residence time and conversion rate. High and productive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

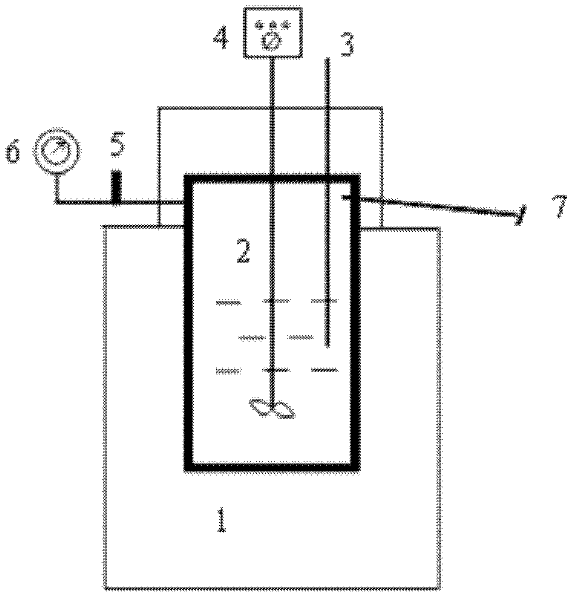

[0023] like figure 1 As shown, the high-pressure reactor includes a kettle body 1 , a stirring paddle 2 , a thermocouple 3 , a magnetically coupled stirrer 4 , a pressure explosion-proof valve 5 , a pressure gauge 6 and an air release valve 7 .

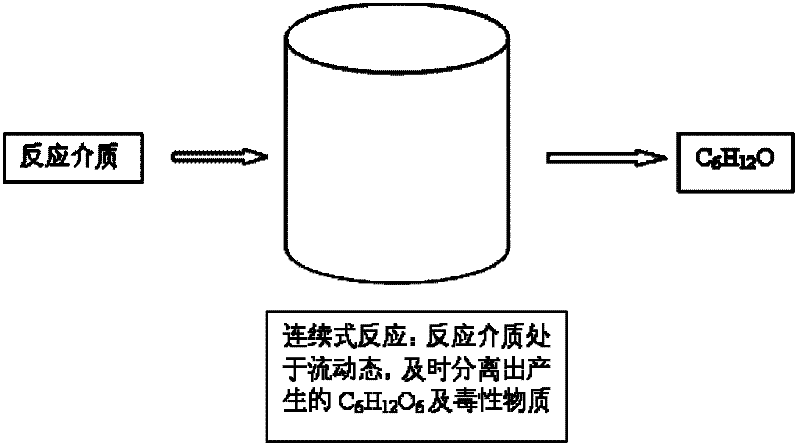

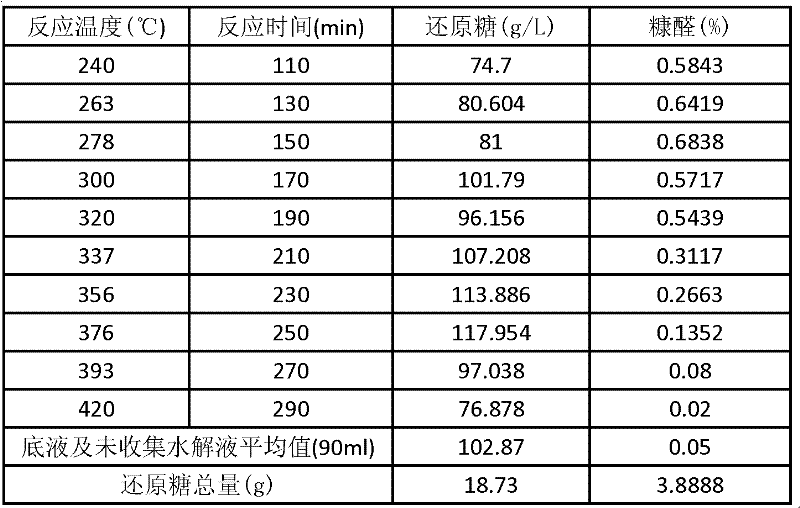

[0024] 2-200 mesh bagasse raw material 30g, the solid-liquid weight ratio in the reaction kettle is 1:9, distilled water is the reaction medium. The reaction starts at 240°C and the water sample is fed, and at the same time, the water outlet is opened to collect the hydrolyzate, 10ml each time. The process of continuous reaction is as follows figure 2 shown. Table 1 shows the effects of different reaction temperatures in the autoclave on the production of reducing sugar and furfural from bagasse.

[0025] Table 1

[0026]

[0027] The yield of reducing sugar in the autoclave was significantly increased, and the yield of furfural was also reduced.

Embodiment 2

[0029] 100-200 mesh bagasse raw material 30g, the solid-liquid weight ratio in the reactor is 1:6, the H of pH=5 2 SO 4 as the reaction medium. The reaction starts at 240°C and the water sample is fed, and at the same time, the water outlet is opened to collect the hydrolyzate, 10ml each time. Table 2 shows the effects of different reaction temperatures in the autoclave on the production of reducing sugar and furfural from bagasse.

[0030] H at pH=5 2 SO 4 The yield of reducing sugar in the high-pressure reactor used as the reaction medium is significantly improved, and the production of reducing sugar and the elimination of furfural are helpful under weak acid conditions, because the weak acid increases the ionization degree of the solution in the super / subcritical reaction, making the straw The cellulose, hemicellulose and lignin are completely separated, and the decomposition of each component of the straw is catalyzed.

[0031] Table 2

[0032]

Embodiment 3

[0034] 2-200 mesh rice straw raw material 30g, the solid-liquid weight ratio in the reactor is 1:12, pH=3 H 2 SO 4 as the reaction medium. The reaction starts at 233°C and the water sample is fed, and at the same time, the water outlet is opened to collect the hydrolyzate, 10ml each time. The effects of different reaction temperatures in the autoclave on the production of reducing sugar and furfural from rice straw are shown in Table 3.

[0035] table 3

[0036]

[0037] The impact of different reaction modes on the yield of reducing sugar is shown in Table 4. In summary, the present invention has the advantages of short residence time of reducing sugar in the reactor, high production efficiency, small product inhibition, and high conversion rate, and can overcome the high pollution, high catalyst consumption, and strong inhibition of biotechnology products in traditional technologies. The problem of low production efficiency.

[0038] Table 4

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com