Treatment method for converting urine to resources and energy

A treatment method and resource-recycling technology, applied in the fields of energy and wastewater treatment, chemical instruments and methods, biochemical equipment and methods, etc., can solve the problems of cost, difficult crop or plant utilization, etc., to maintain pH value, prevent pH value The effect of excessive reduction and reduction of production load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

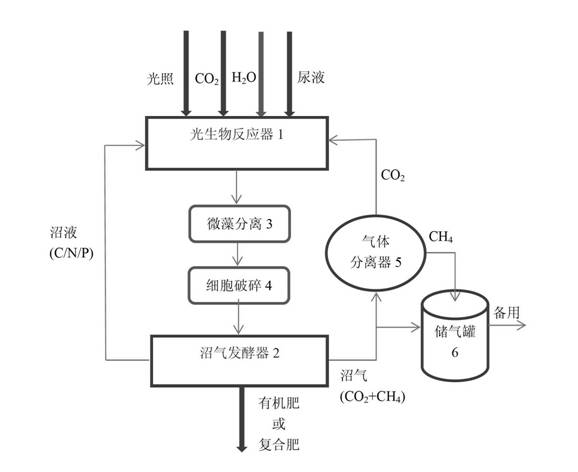

[0037] A kind of method that is used for urine resource and energy, this method comprises the following steps: (1) put 1000m in photobioreactor 3 water, take 1m 3 The green river water is inoculated with microalgae, and poured into the photobioreactor (2) Take 200L of urine and add it into the bioreactor, and acclimatize it under natural sunlight. Add 200L of urine every day, and the acclimatization is completed after 10 days. After that, 2L of urine per day was steadily added to the photobioreactor to enter the stable culture stage, and the biomass at this time was 5g / L. (3) The microalgae are separated by filtration, and put into a biogas fermenter after ultrasonic crushing. (4) The microalgae stays in the biogas fermenter for 10 days, 40% of which are converted into biogas, 30% into biogas slurry, and 30% into biogas residue. The biogas enters the gas storage tank for standby, the biogas slurry flows back to the photobioreactor, and the biogas residue is used as fertilize...

Embodiment 2

[0039] A kind of method that is used for urine resource recovery and energy conversion, this method comprises the following steps: (1) put 1m in photobioreactor 3 Water, take 1L of green river water to inoculate microalgae, and pour it into the photobioreactor. (2) Take 50mL of urine and add it into the bioreactor, and acclimatize it under natural sunlight, adding 50mL of urine every day, and the acclimatization is completed after 10 days. After that, 500mL of urine per day was steadily added to the photobioreactor to enter the stable culture stage, and the biomass at this time was 0.5g / L. (3) The microalgae are separated by filtration, and put into a biogas fermenter after ultrasonic crushing. (4) The microalgae stays in the biogas fermenter for 3 days, 40% of which are converted into biogas, 40% into biogas slurry, and 20% into biogas residue. The biogas enters the gas storage tank for standby, the biogas slurry flows back to the photobioreactor, and the biogas residue is ...

Embodiment 3

[0041] A kind of method that is used for urine resource recovery and energy conversion, this method comprises the following steps: (1) put 5m in photobioreactor 3 Water, buy Chlorella (Chlorella), and inoculate into the photobioreactor after expansion. (2) Take 10L of urine and add it into the bioreactor, and carry out proliferative culture on it under natural sunlight, adding 10L of urine every day, and it will be completed after 10 days. After that, 100L of urine per day was steadily added to the photobioreactor to enter the stable culture stage, and the biomass at this time was 50g / L. (3) Microalgae are separated by filtration and directly put into a biogas fermenter. (4) Microalgae stay in the biogas fermenter for 45 days, 50% of which are transformed into biogas, 30% into biogas slurry, and 20% into biogas residue. The biogas enters the gas storage tank for standby, the biogas slurry flows back to the photobioreactor, and the biogas residue is used as fertilizer for sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com