Hardness reduction treatment method for lead-zinc smelting industrial wastewater subjected to up-to-standard treatment

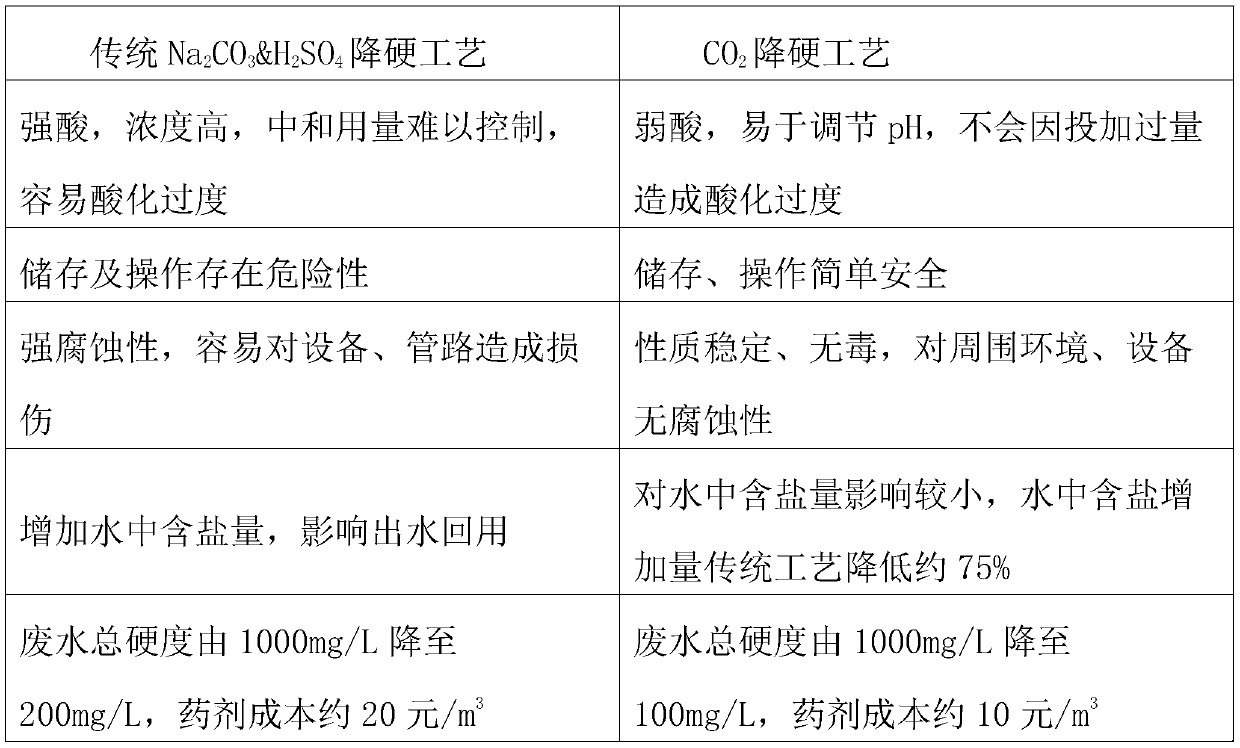

A technology for industrial wastewater and treatment methods, applied in filtration treatment, sedimentation treatment, water softening, etc., can solve the problems of increasing the salt content of wastewater, increasing the investment cost and operating cost of zero discharge of wastewater, etc., to reduce production load, reduce Initial investment and operating costs, the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A treatment method for reducing the hardness of the lead-zinc smelting industrial wastewater after the standard treatment, the specific steps are:

[0023] 1) Store liquid carbon dioxide in a storage tank, convert it into gaseous carbon dioxide through an air-temperature vaporizer, and transport it to a dissolved gas reactor;

[0024] 2) Pump high-hardness reclaimed water with a total hardness of 1691mg / l and a pH of 9.33 to the dissolved air reactor to react with gaseous carbon dioxide, and consume 0.3-0.5m of gaseous carbon dioxide per cubic meter of water 3 ;

[0025] 3) After the liquid in step 2) is added to the sodium hydroxide solution, it enters the 1# reaction pool, 2# reaction pool, 3# reaction pool, and 4# reaction pool for reaction, and the single consumption of sodium hydroxide per cubic meter of water is 0.5-0.8kg , the reaction temperature is normal temperature, the reaction time is 1h, and the control reaction pH is 10.85;

[0026] 4) The liquid after ...

Embodiment 2

[0028] A treatment method for reducing the hardness of the lead-zinc smelting industrial wastewater after the standard treatment, the specific steps are:

[0029] 1) Store liquid carbon dioxide in a storage tank, convert it into gaseous carbon dioxide through an air-temperature vaporizer, and transport it to a dissolved gas reactor;

[0030] 2) Pump high-hardness reclaimed water with a total hardness of 1691mg / l and a pH of 9.33 to the dissolved air reactor to react with gaseous carbon dioxide, and consume 0.3-0.5m of gaseous carbon dioxide per cubic meter of water 3 ;

[0031] 3) After the liquid in step 2) is added to the sodium hydroxide solution, it enters the 1# reaction pool, 2# reaction pool, 3# reaction pool, and 4# reaction pool for reaction, and the single consumption of sodium hydroxide per cubic meter of water is 0.5-0.8kg , the reaction temperature is normal temperature, the reaction time is 2h, and the control reaction pH is 11.14;

[0032] 4) The liquid after ...

Embodiment 3

[0034] A treatment method for reducing the hardness of the lead-zinc smelting industrial wastewater after the standard treatment, the specific steps are:

[0035] 1) Store liquid carbon dioxide in a storage tank, convert it into gaseous carbon dioxide through an air-temperature vaporizer, and transport it to a dissolved gas reactor;

[0036] 2) Pump high-hardness reclaimed water with a total hardness of 1050mg / l and a pH of 9.26 to the dissolved air reactor to react with gaseous carbon dioxide, and consume 0.3-0.5m of gaseous carbon dioxide per cubic meter of water 3 ;

[0037] 3) After the liquid in step 2) is added to the sodium hydroxide solution, it enters the 1# reaction pool, 2# reaction pool, 3# reaction pool, and 4# reaction pool for reaction, and the single consumption of sodium hydroxide per cubic meter of water is 0.5-0.8kg , the reaction temperature is normal temperature, the reaction time is 3h, and the control reaction pH is 11.42;

[0038] 4) The liquid after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com