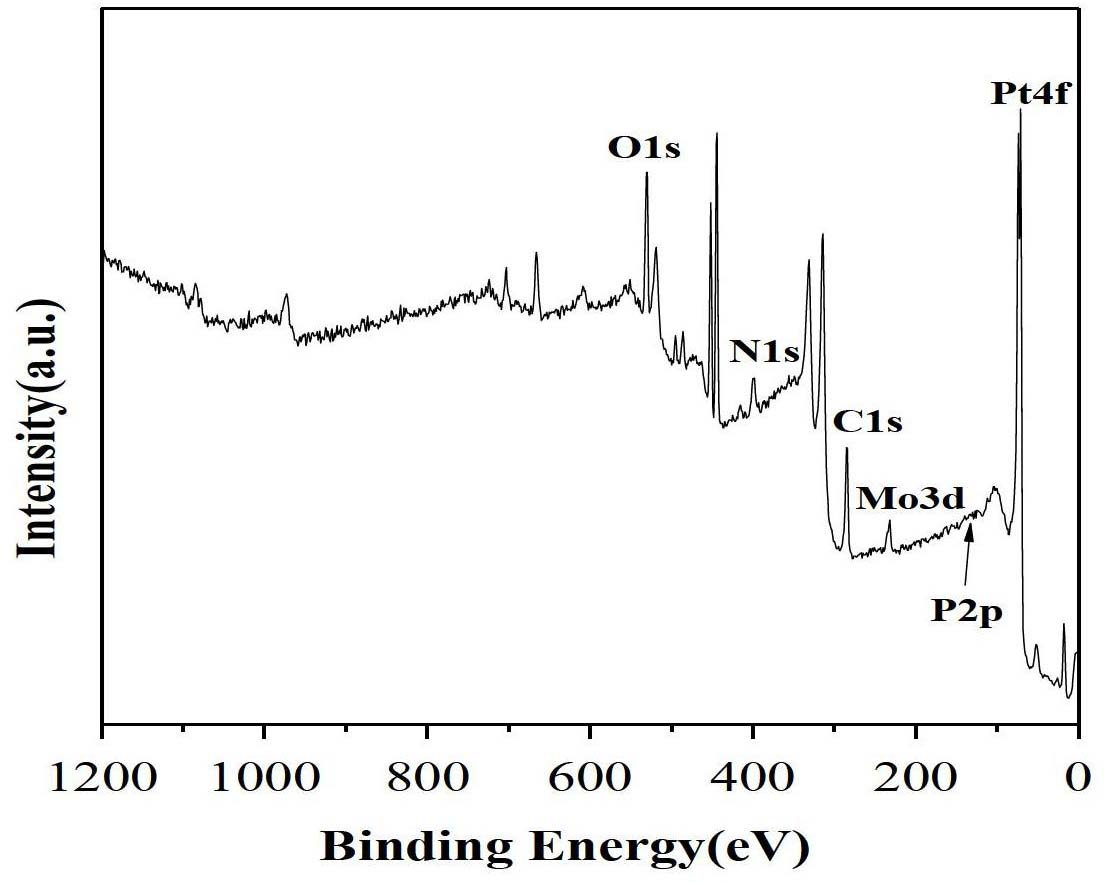

Preparation method of direct methanol fuel cell anode composite membrane catalyst

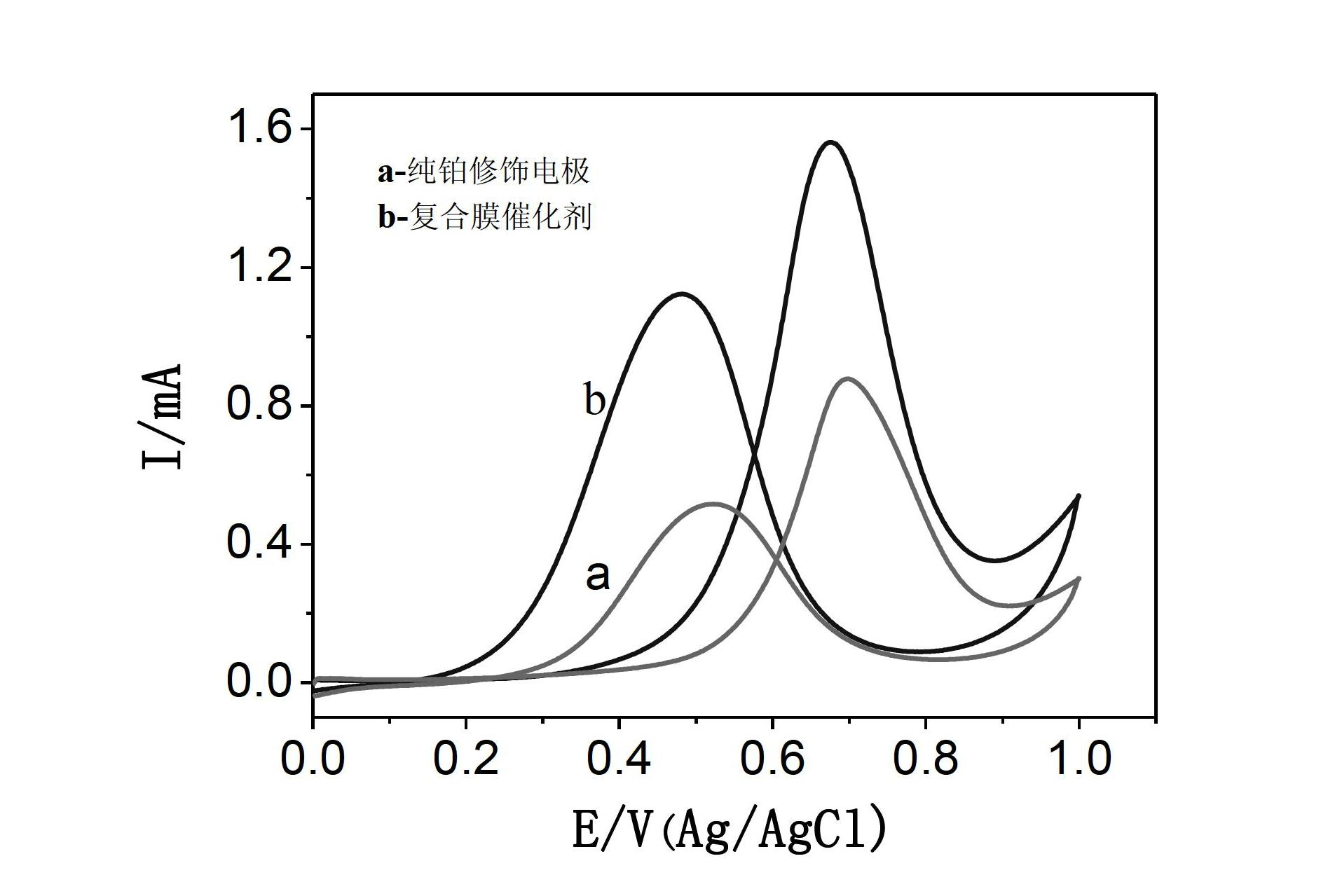

A methanol fuel cell and composite membrane technology, which is applied in catalyst activation/preparation, battery electrodes, chemical instruments and methods, etc., can solve the problems of easy agglomeration, restrict the application of graphene, etc., and achieves simple preparation method, electrocatalytic activity and resistance. The effect of improving CO poisoning ability and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

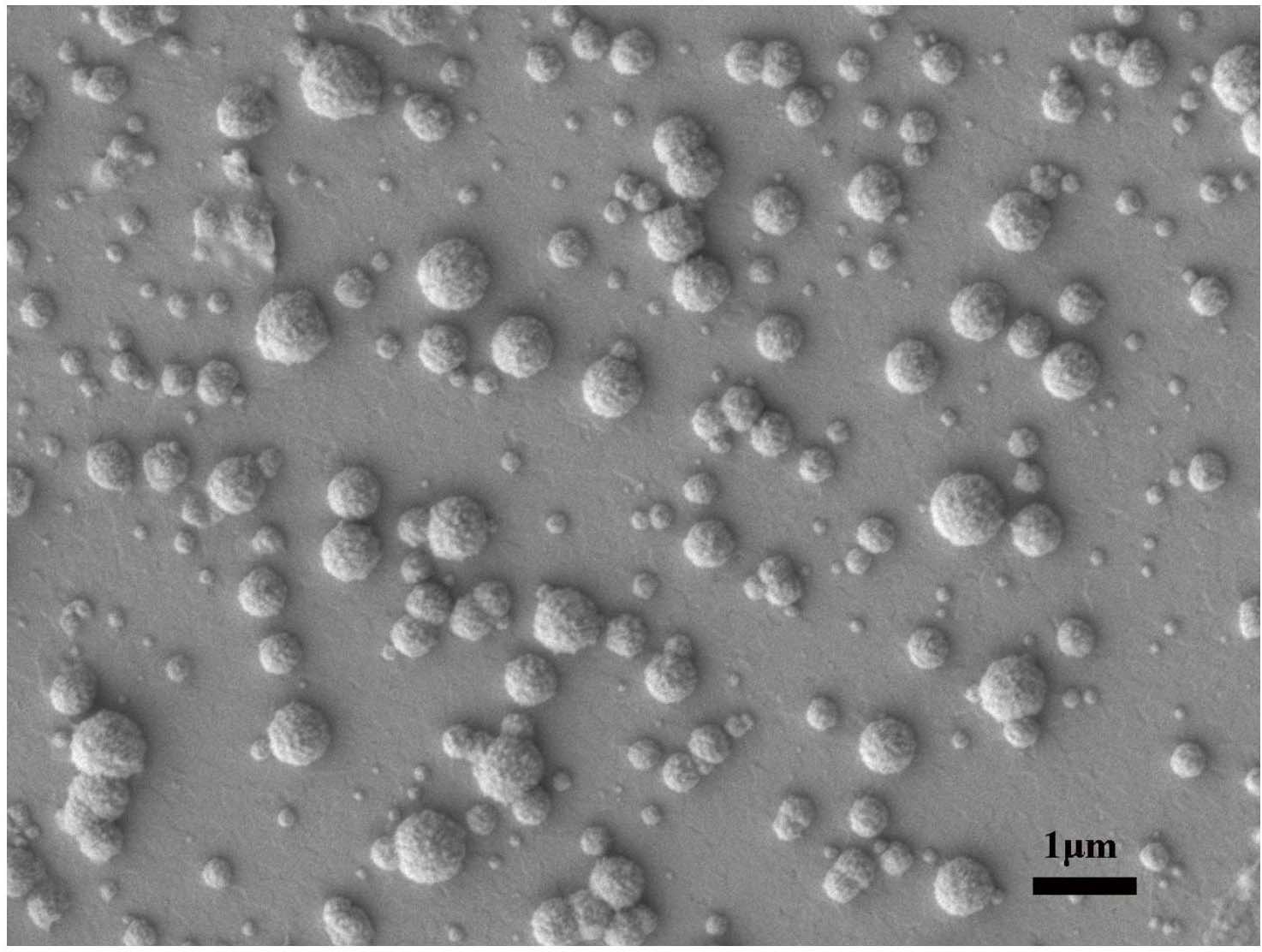

Embodiment 1

[0028] 1. Glassy carbon electrode substrate pretreatment:

[0029] The glassy carbon electrode substrate was first coated with 1.0, 0.3 and 0.05 μm α-Al 2 o 3 powder polishing, followed by ultrasonic cleaning in ethanol solution and distilled water for 10 min, at 0.5 mol L -1 h 2 SO 4 Control the potential range in the solution from -0.25V to 1.25V to carry out cyclic potential scanning until a stable standard cyclic voltammogram is obtained.

[0030] 2. Preparation of PEI functionalized modified graphene

[0031] Dissolve 0.05g of graphite oxide in 100mL of deionized water, form a uniform dispersion after ultrasonication for 30min, add 0.8g of PEI, reflux at 60°C for 12h under stirring conditions, cool to room temperature, add 2 drops of hydrazine hydrate and vigorously stir for 5min, and stir at 96°C under stirring conditions Reflux for 12 hours, centrifuge to separate the precipitate, wash with deionized water until neutral to obtain PEI functionalized graphene, the pr...

Embodiment 2

[0041] 1. Glassy carbon electrode substrate pretreatment:

[0042] The pretreatment method of the glassy carbon electrode substrate is the same as in Example 1.

[0043] 2. Preparation of PDDA functionalized graphene

[0044] Dissolve 0.10g of graphite oxide in 200mL of deionized water, form a uniform dispersion after ultrasonication for 40min, add 3.0g of PDDA, reflux at 80°C for 12h under stirring conditions, cool to room temperature, add 2 drops of hydrazine hydrate, stir vigorously for 5min, and reflux at 110°C under stirring conditions After 24 hours, a water-soluble functionalized modified graphene solution was obtained, and part of the precipitate was separated by centrifugation after ultrasonication for 30 minutes. After the solution was ultrasonicated again, the precipitated part was centrifuged to obtain PDDA functionalized modified graphene dispersed uniformly and long-term stable in the aqueous solution. The product was marked as PDDA- GN, a solution with a concen...

Embodiment 3

[0051] 1. Glassy carbon electrode substrate pretreatment:

[0052] The pretreatment method of the glassy carbon electrode substrate is the same as in Example 1.

[0053] 2. Preparation of PEI functionalized modified graphene

[0054] The preparation method of PEI functionalized modified graphene is the same as that of Example 1.

[0055] 3. Composite film self-assembly:

[0056] Place the pretreated electrode in 0.5mol / L H 2 SO 4 Cycle scanning within the potential range of -0.8 ~ 1.0V until a stable response curve is obtained. Then rinse it with deionized water, dry it slowly with nitrogen, immerse it in 1mg / mL PEI-GN solution for 20min, take it out, rinse it with deionized water, and dry it slowly with nitrogen gas to obtain a glass modified with a layer of PEI-GN. Carbon electrode substrate. Immerse the dried modified glassy carbon electrode substrate in 10mmol / L polyoxometalate H 3 wxya 11 o 40 (0.5mol / LH 2 SO 4 is the solvent) solution, soak for 20min, that is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com