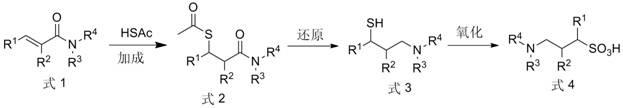

Method for preparing substituted homotaurine from alpha, beta-unsaturated amide

A high taurine, unsaturated technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of raw material limitation, troublesome desalination and purification process, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1-Amino-3-butanesulfonic acid 4a preparation of

[0046] In a 50 mL three-necked flask, 0.851 g (10 mmol) of 2-butenamide was added to 15 mL CH 2 Cl 2 , followed by dropwise addition of 5 drops of anhydrous triethylamine. Heated to reflux under nitrogen protection, added dropwise 0.952 g (12.5 mmol) of thioacetic acid, and refluxed for 20 h. Cool to room temperature, remove the solvent and then separate by silica gel column chromatography [petroleum ether (PE): ethyl acetate (EA) = 1:2, v / v] to obtain 1.251 g of intermediate 3-acetylthiobutyramide, yield 77.6% .

[0047] In a 100 mL single-necked bottle, 1.520 g (40 mmol) LiAlH 4 Add to 30 mL of anhydrous THF. Then 5 mL THF solution containing 0.645 g (4 mmol) 3-acetylthiobutyramide was added dropwise, heated to reflux for 18 h, and quenched with water in an ice-water bath after returning to room temperature, then added 10 mL of water and stirred for 12 h. Filtration, filtrate with CH 2 Cl 2 Three extracti...

Embodiment 2

[0049] 2-Methyl-3-aminopropanesulfonic acid 4b preparation of

[0050] According to the method described in Example 1, 2-methacrylamide was used instead of 2-butenamide as a raw material to obtain a colorless crystal intermediate of 2-methyl-3-acetylthiopropionamide with a yield of 95%. Melting point 84-86 o C; Colorless crystals of 2-methyl-3-aminopropanesulfonic acid were obtained after reduction and oxidation, yield 70%, melting point 234-238 o c. Literature melting point: 260-265 o c. 1 H NMR (400 MHz, D 2 O) δ: 3.15 (dd, J = 6.0, 13.2 Hz, 1H in SCH 2 ), 2.93 (dd, J = 6.8, 14.4 Hz, 1H in NCH 2 ), 2.90 (dd, J = 6.8, 13.2 Hz, 1H in SCH 2 ), 2.87 (dd, J= 6.0, 14.4 Hz, 1H in NCH 2 ), 2.32 (ttq, J = 6.8, 6.0,6.8 Hz, 1H, CH), 1.10 (d, J = 6.8 Hz, 3H, CH 3 ); 13 C NMR (100 MHz, D 2 O) δ: 54.7, 44.2, 28.7, 17.0; IR n (cm -1 ): 3451 (br, s, NH, OH), 1280 (SO), 1176 (SO).

Embodiment 3

[0052] 2-Methyl-1-amino-3-butanesulfonic acid 4c preparation of

[0053] According to the method described in Example 1, with 2-methyl-2-butenamide instead of 2-butenamide as raw material, 2-methyl-3-acetylthiobutyramide was obtained with a yield of 75%. Crystal intermediate, melting point 136-138 o C; After reduction and oxidation, oily 2-methyl-1-amino-3-butanesulfonic acid was obtained in 40% yield. 1 H NMR (400 MHz, D 2 O) δ: 3.27 (dd, J = 5.6, 13.2 Hz, 1H in NCH 2 ), 2.96 (dq, J = 2.8, 7.2 Hz, 1H, SCH), 2.82 (dd, J = 8.4, 13.2 Hz, 1H in NCH 2 ), 2.42 (dddq, J = 2.8, 5.6, 8.4, 7.2 Hz, 1H, CH), 1.21 (d, J = 7.2 Hz, 3H, CH 3 ), 1.05 (d, J = 7.2 Hz, 3H, CH 3 ); 13 C NMR (100 MHz, D 2 O) δ: 58.5, 41.2, 32.3, 15.4, 9.8; IR n (cm -1 ): 2976 (br, s, NH, OH), 1205 (SO), 1030 (SO). HRMS (ESI, m / z ) calcd. for C 5 h 13 NO 3 S [M+H] + m / z : 168.0689; found: 168.0682.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com