Method for preparing gold/titanium dioxide core-shell nanoparticle

A technology of nanoparticles and core-shell structure, which is applied in the field of preparation of gold/titanium dioxide core-shell structure nanoparticles, can solve the problems of complex synthesis process, harsh reaction conditions, long production cycle, etc., and achieve simple process flow, mild reaction conditions, The effect of the integrity of the shell structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Preparation of carbon nanospheres containing gold nuclei

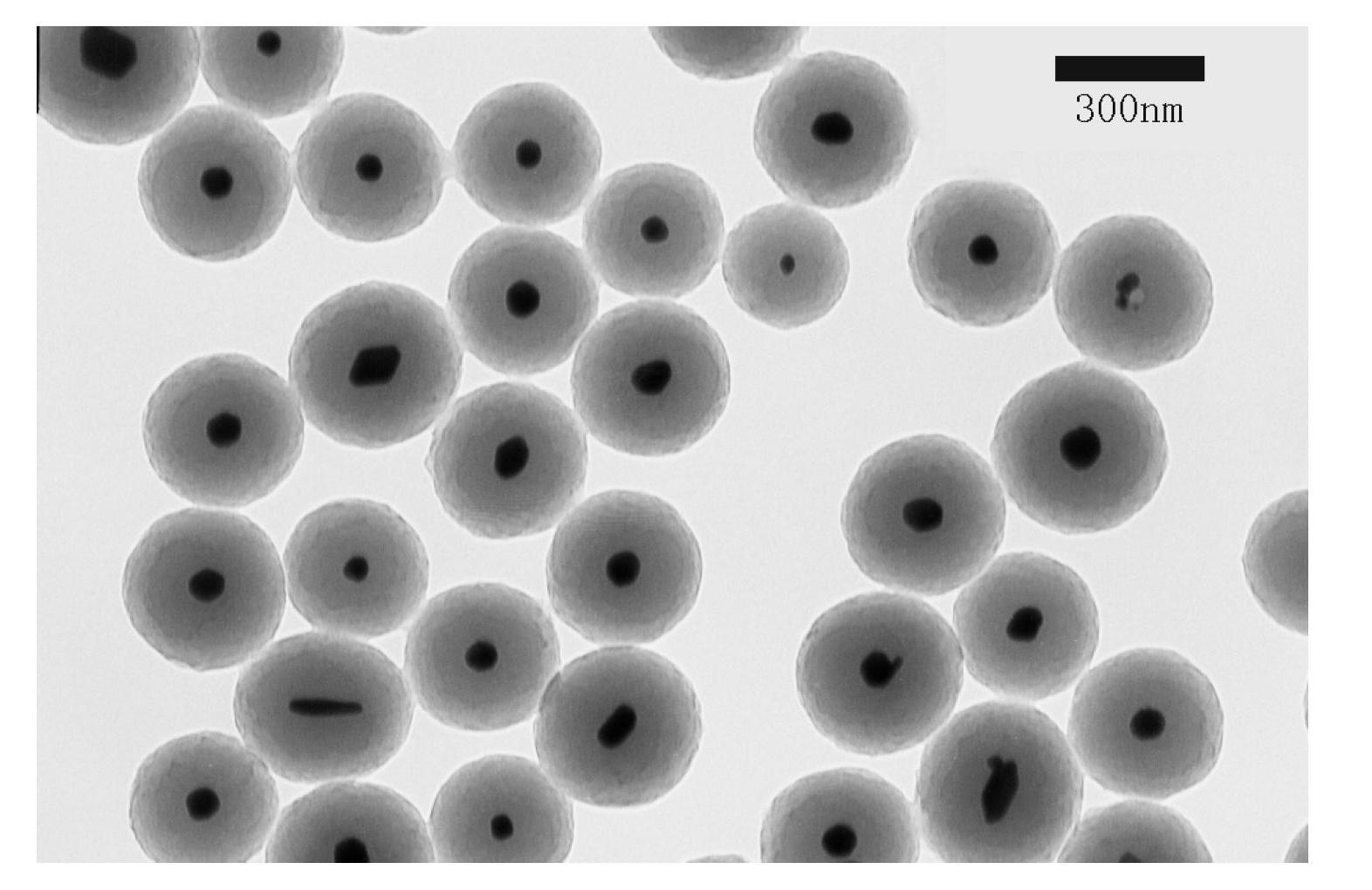

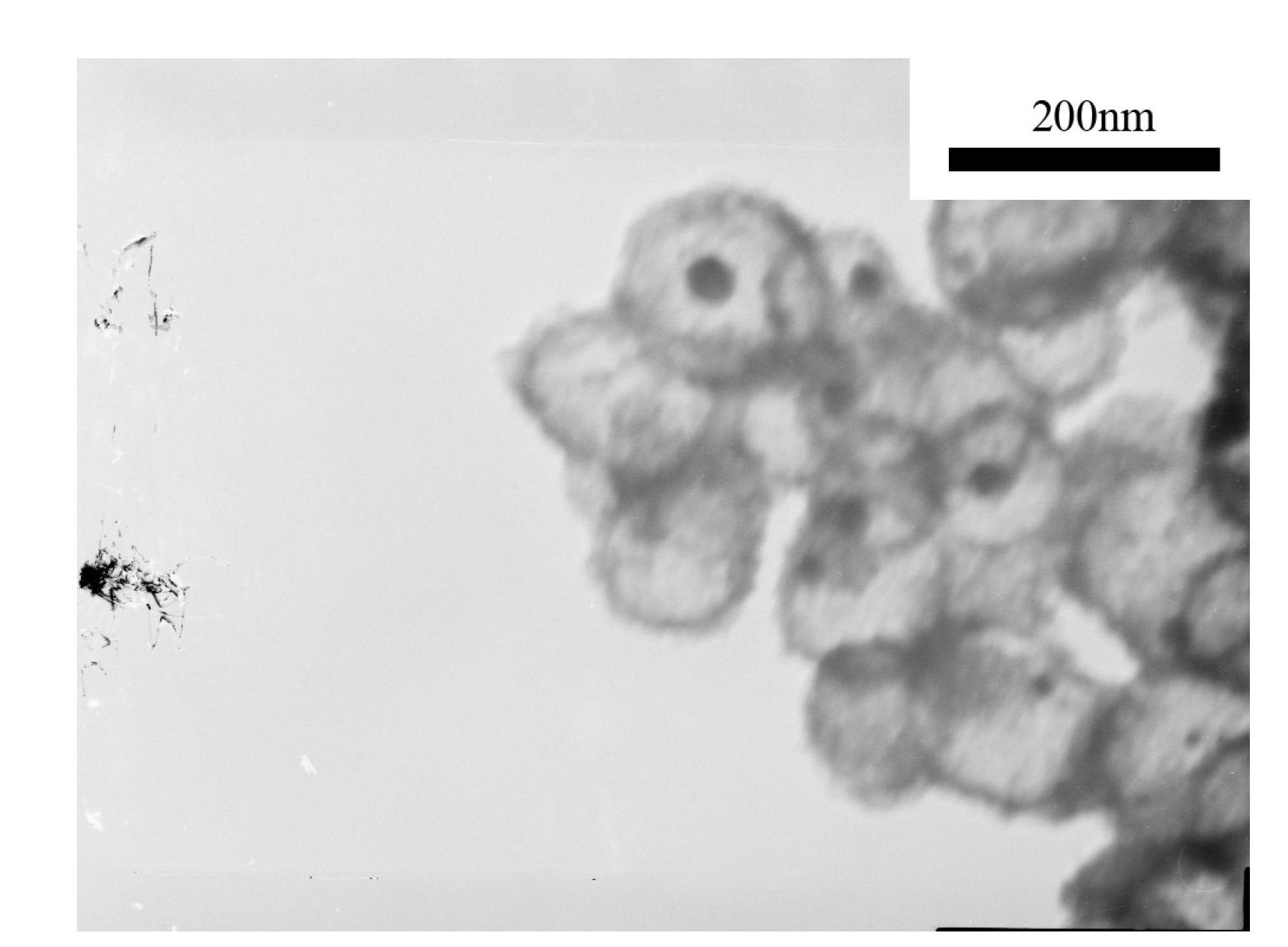

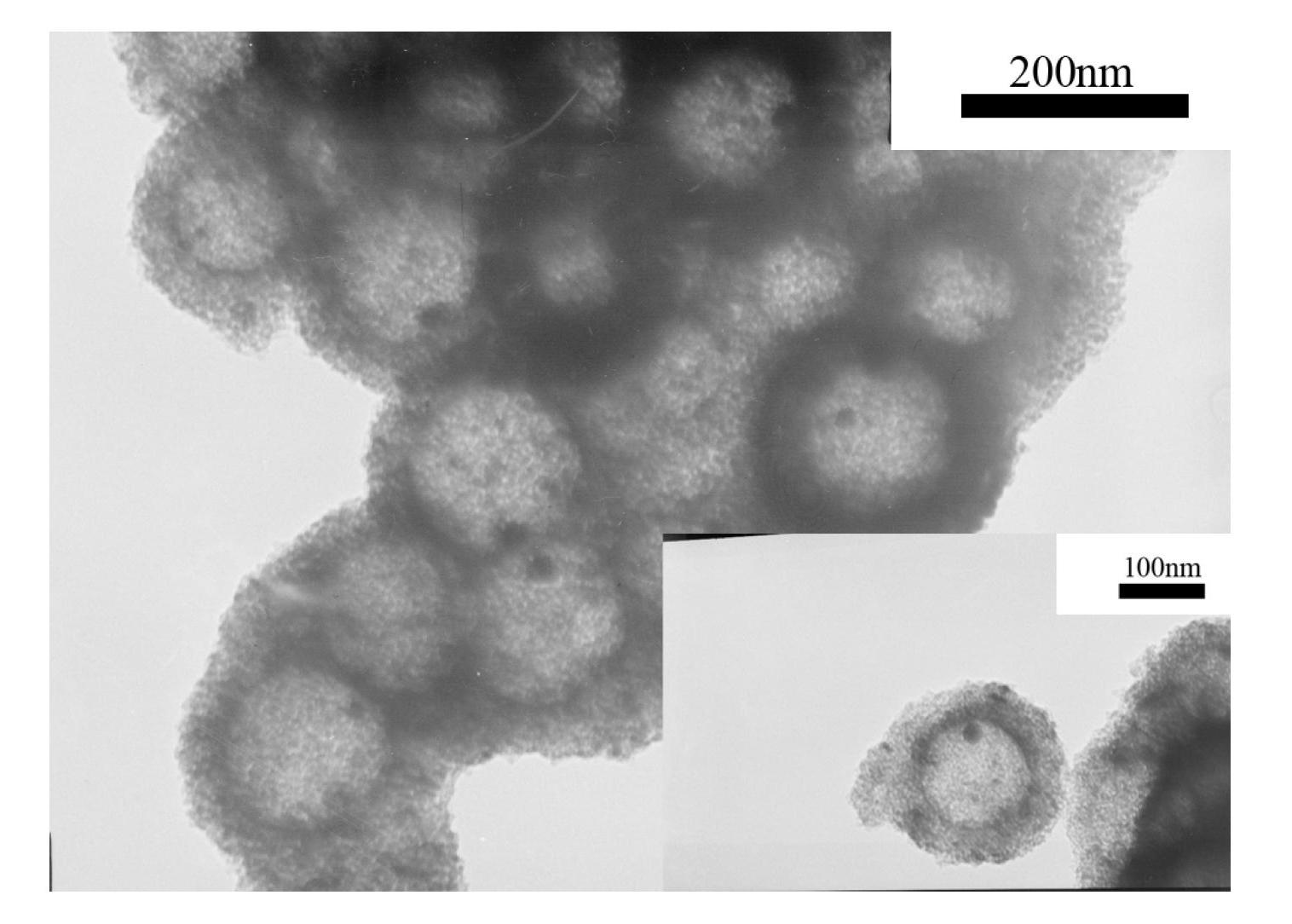

[0023] Dissolve 2g of sugar compounds in 35ml of deionized water to make a 0.289mol / L solution, then add 170μL of 0.0243mol / L chloroauric acid aqueous solution, mix well, and put it into a 50ml polytetrafluoroethylene reaction kettle , reacted under hydrothermal conditions at 180°C for 4 hours, filtered and washed to obtain the product, washed three times with water, then washed three times with alcohol, and then dried at 40°C for 12 hours to obtain carbon nanospheres containing gold nuclei. The diameter of carbon spheres is 160-200nm, and the diameter of gold particles is 20-40nm.

[0024] 2) Titanium dioxide shells are coated on the nanocarbon spheres containing gold nuclei

[0025] Take 0.02g of the prepared gold-nucleated carbon nanospheres, disperse them in 20ml of absolute ethanol, make a 0.1g / L solution, and ultrasonically vibrate for 15 minutes at room temperature, then add 0.2ml of ammonia water, an...

Embodiment 2

[0029] 1) Preparation of carbon nanospheres containing gold nuclei

[0030] Dissolve 4g of sugar compounds in 35ml of deionized water to make a 0.577mol / L solution, then add 170μL of 0.0243mol / L chloroauric acid aqueous solution, mix well, and put it into a 50ml polytetrafluoroethylene reaction kettle , reacted under hydrothermal conditions at 190°C for 3 hours, filtered and washed to obtain the product, washed three times with water, then washed three times with alcohol, and then dried at 40°C for 12 hours to obtain carbon nanospheres containing gold nuclei. Carbon spheres have a diameter of 140-190nm, and gold particles have a diameter of 20-40nm.

[0031] 2) Titanium dioxide shells are coated on the nanocarbon spheres containing gold nuclei

[0032] Take 0.02g of the prepared gold-nucleated carbon nanospheres, disperse them in 20ml of absolute ethanol, make a 0.1g / L solution, and ultrasonically vibrate for 15 minutes at room temperature, then add 0.2ml of ammonia water, an...

Embodiment 3

[0036] 1) Preparation of carbon nanospheres containing gold nuclei

[0037] Dissolve 1g of sugar compound in 35ml of deionized water to make a solution of 0.144mol / L, then add 340μL of 0.0243mol / L chloroauric acid aqueous solution, mix well, and put it into a 50ml polytetrafluoroethylene reaction kettle , reacted under hydrothermal conditions at 200°C for 1 hour, filtered and washed to obtain the product, washed with water three times, then washed with alcohol three times, and then dried at 40°C for 12 hours to obtain carbon nanospheres containing gold nuclei. Carbon spheres have a diameter of 150-300nm, and gold particles have a diameter of 40-60nm.

[0038] 2) Titanium dioxide shells are coated on the nanocarbon spheres containing gold nuclei

[0039] Take 0.02g of the prepared gold-nucleated carbon nanospheres, disperse them in 10ml of absolute ethanol, make a 0.2g / L solution, and ultrasonically vibrate for 15 minutes at room temperature, then add 0.1ml of ammonia water, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com