Foamed ceramic insulation board and preparation method thereof

A technology of foam ceramics and thermal insulation boards, which is applied in the field of building materials, can solve the problems of complex manufacturing process, difficult control of foaming pores, and difficult construction, and achieve the effect of simple construction process and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

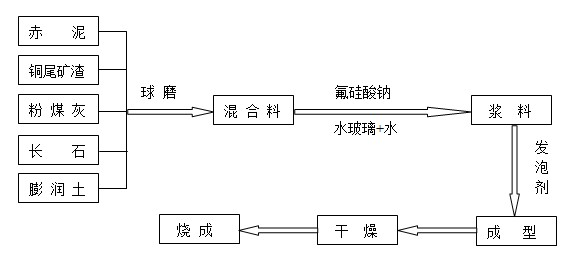

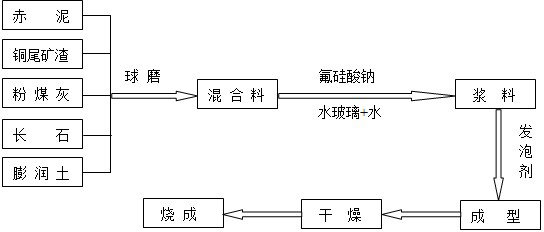

[0032] according to figure 1 As shown, take 40g of red mud, 160g of copper tailing slag, 160g of fly ash, 40g of feldspar, and 20g of bentonite, mix them by ball milling, add 32g of sodium fluorosilicate and stir evenly, then add 400g of water glass, and add 20g of water and stir evenly Finally, add 20g of hydrogen peroxide and stir for 30s, then pour it into the mold immediately; dry it at a temperature lower than 50-60°C for 24 hours and put it in the furnace for sintering; the sintering temperature is 900-1000°C, and the sintering system has strict requirements. Requirements: Room temperature-(130-150°C) heating rate is 0.8-1°C / min; (130-150°C) heat preservation 1h-3h; (130-150°C)-(600-700°C) heating rate is 1.5 -2°C / min; (600-700°C)-X (900-1000°C) heating rate is 0.5-1.2°C / min; keep warm at X (900-1000°C) for 1-2.5h, press 0.5 Cooling at a rate of -1°C / min.

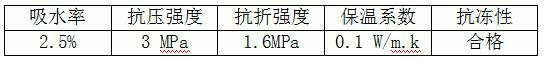

[0033] The characteristics of the sample are as follows: All performance indicators have reached the national A-l...

Embodiment 2

[0036]Take 120g of copper tailings slag, 120g of fly ash, 30g of feldspar, and 15g of bentonite, mix them by ball milling, add 25g of sodium fluorosilicate and stir evenly, then add 220g of water glass, add 25g of water and stir evenly, then add 30g of aluminum powder Immediately after stirring for 30 s, it was poured into a mold for molding; the drying and sintering steps were the same as in Example 1.

[0037] The characteristics of the sample are as follows: All performance indicators have reached the national A-level standard for existing exterior wall tiles.

[0038]

Embodiment 3

[0040] Take 40g of red mud, 160g of copper tailings slag, 160g of fly ash, 40g of feldspar, and 20g of bentonite. After mixing by ball milling, add 32g of sodium fluorosilicate and stir evenly, then add 400g of water glass, and at the same time add 20g of water. Stir 50g of air bubbles and 3g of polyvinyl alcohol made of rosin soap and water at a weight ratio of 1:20 and pour it into a mold immediately; the drying and sintering steps are the same as in Example 1.

[0041] The characteristics of the sample are as follows: All performance indicators have reached the national A-level standard for existing exterior wall tiles.

[0042]

[0043] Get copper tailings slag 130g, fly ash 120g, feldspar 35g, bentonite 45g, add 48g sodium fluorosilicate and stir after ball milling and mix, add 160g of water glass after adding 64g water at the same time and stir, add by weight ratio Mix 60g of air bubbles and 1.5g of bone glue made of rosin soap and water at a ratio of 1:40 and pour it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com