Preparation method of sulfonamide

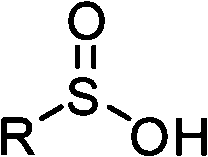

A technology of sulfonamide and sulfinic acid, which is applied in the preparation of sulfonate amide, organic chemistry, etc., can solve the problems of high activity, sensitivity, and difficulty in storage of sulfonated reagents, and achieve easy industrial production, improved reaction system, and stable properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

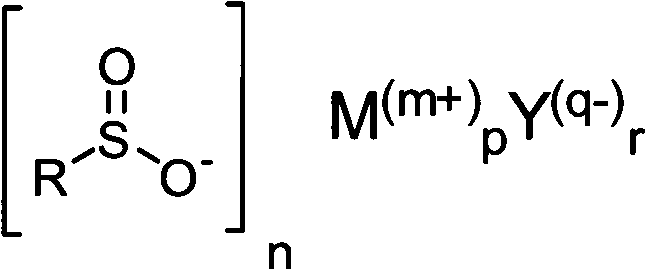

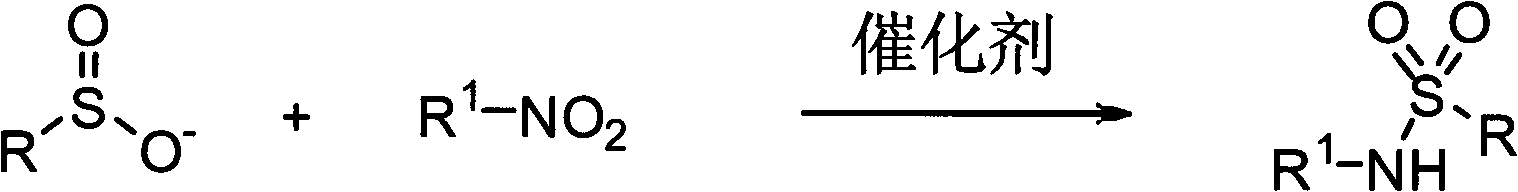

[0020] The present invention uses sulfinic acid or sulfinate and nitro compounds in the presence of catalysts and without any additives under an inert gas atmosphere, using transition metals or transition metal compounds as catalysts, and the reaction temperature is 20°C- Heating at 200°C for 3 to 30 hours produces sulfonamides without substantially producing transitional acylation by-products.

[0021]

[0022] The reaction formula of sulfinic acid salt of the present invention and nitro compound

[0023] The technical scheme of the present invention is realized in the following manner: the preferred catalyst is selected from Pd, Ni, Fe, Au, Rh, Pt, Ru, Ir, Ag, Cu, Mn, Co. The metals can optionally be used in elemental form, as complexes or as salts. Particular preference is given to using palladium compounds, also particular preference to copper compounds, more particularly preferably cuprous chloride or cuprous bromide.

[0024] The reaction may optionally be carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com