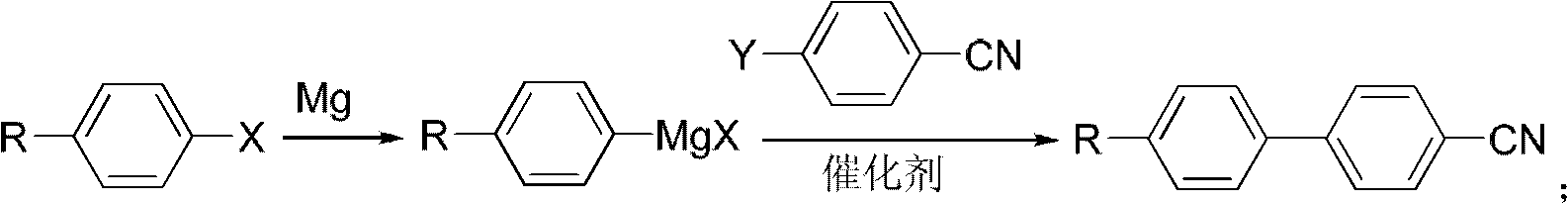

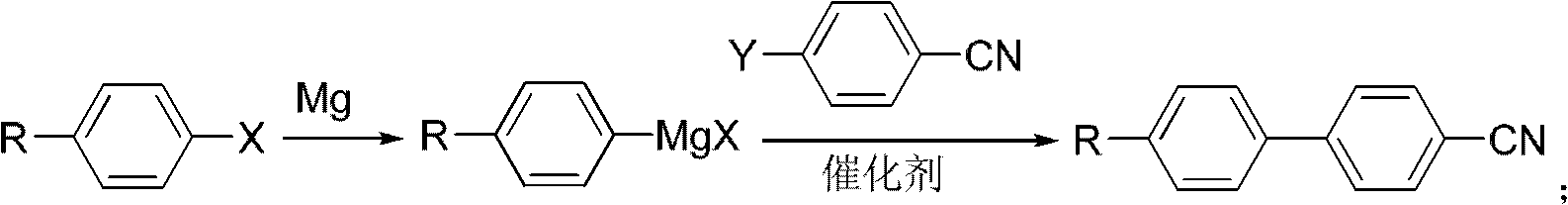

Production process for biphenylnitrile type liquid crystal material

A technology of liquid crystal material and production process, which is applied in the field of production process of biphenyl nitrile liquid crystal material, can solve problems such as limited supply of catalyst market, unsatisfactory resistivity, unqualified product color, etc., and achieve easy industrialized mass production, The effect of less by-products and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Under the protection of nitrogen, put 10 mmoles of iodine, 10 moles of metal magnesium chips and 5 liters of anhydrous tetrahydrofuran into the reaction kettle in turn, heat and keep the reaction temperature of tetrahydrofuran reflux, drop 10 moles of 4-n-butylchlorobenzene Add in the above-mentioned reaction kettle, dropwise time is 12 hours, continue reflux reaction 2 hours after dropwise addition and make the tetrahydrofuran solution of corresponding 4-n-butanyl phenylmagnesium chloride Grignard reagent; Then put the above-mentioned Grignard reagent The tetrahydrofuran solution was dripped into a reaction kettle containing 0.5 moles of manganese dichloride, 10 moles of 4-bromoxynil and 5 liters of anhydrous tetrahydrofuran under the protection of nitrogen. The dropping temperature was 0°C, and the dropping time was 8 hours. After the addition is complete, continue the heat preservation reaction for 2 hours to end the reaction, filter and recover the metal salt, carry ...

Embodiment 2

[0022] Under the protection of nitrogen, put 15 mmoles of iodine, 10 moles of magnesium metal chips and 5 liters of anhydrous tetrahydrofuran into the reaction kettle in turn, heat and keep the reaction temperature of tetrahydrofuran reflux, add 9.8 moles of 4-ethylbromobenzene dropwise In the above-mentioned reaction kettle, the dropwise addition time is 4 hours, and after the dropwise addition, the reflux reaction is continued for 3 hours to obtain a tetrahydrofuran solution of the corresponding 4-ethylphenylmagnesium bromide Grignard reagent; then the above-mentioned Grignard reagent The tetrahydrofuran solution was dripped into a reaction kettle containing 0.5 moles of 1,1'-bis(diphenylphosphino)ferrocene nickel chloride, 10.5 moles of 4-bromoxynil and 5 liters of anhydrous tetrahydrofuran under nitrogen protection. The adding temperature is -10°C, the dropping time is 4 hours, and the reaction is continued for 2 hours after the dropping is completed, the metal salt is reco...

Embodiment 3

[0024] Under the protection of nitrogen, put 10 mmoles of iodine, 10 moles of magnesium metal chips and 5 liters of anhydrous tetrahydrofuran into the reaction kettle in turn, heat and keep the reaction temperature of tetrahydrofuran reflux, and drop 9.9 moles of 4-n-octylbromobenzene Add in the above-mentioned reaction kettle, dropwise time is 5 hours, continue reflux reaction for 3 hours after dropwise addition and make the tetrahydrofuran solution of corresponding 4-n-octylphenylmagnesium bromide Grignard reagent; Then put the above-mentioned Grignard The tetrahydrofuran solution of the reagent was dropped into a reaction kettle containing 0.5 moles of 1,1'-bis(diphenylphosphino)ferrocenepalladium chloride, 10 moles of 4-bromobenzonitrile and 5 liters of anhydrous tetrahydrofuran under nitrogen protection. , the dropping temperature is 5°C, the dropping time is 6 hours, after the dropping is completed, the insulation reaction is continued for 2 hours to end the reaction, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com