Multi-aperture nerve repairing tube and preparation method and application thereof

A nerve repair and multi-aperture technology, applied in the field of medical materials, can solve problems such as slow degradation, inability to maintain a stable structure, and poor plasticity of materials, and achieve good plasticity and mechanical properties, repair spinal nerve injuries, and good tissue compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

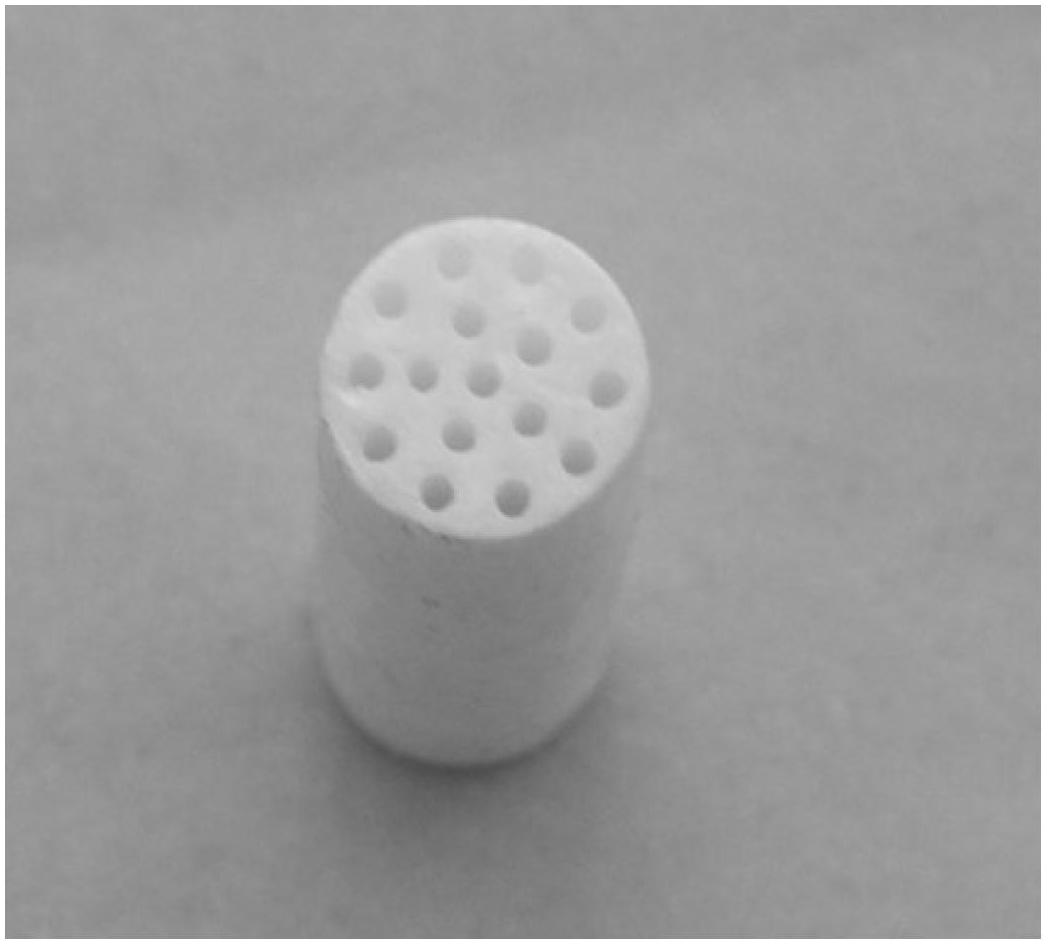

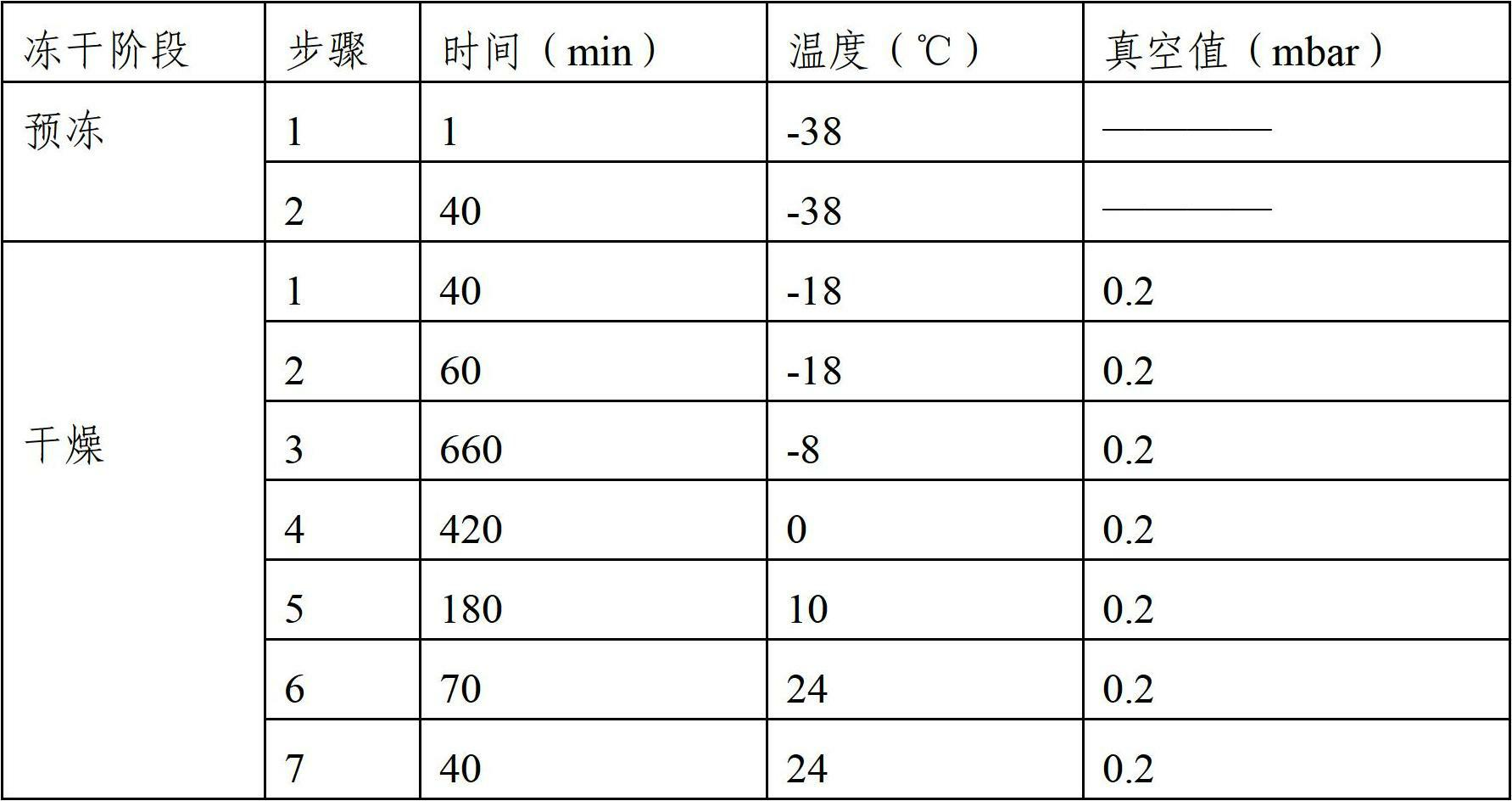

[0034] The preparation method of the multi-aperture nerve repair catheter of the present invention takes a collagen slurry concentration of 5%, a repair tube length of 30mm, a diameter of 8mm, a microtube diameter of 0.6mm, and a model containing 16 parallel microtube channels as an example. The production method includes the following steps:

[0035] 1. Preparation of slurry

[0036] 1.10.05M acetic acid solution preparation

[0037] Take 2-6ml of glacial acetic acid into a 1000ml conical flask, add sterile water to make the volume to 1000ml, and mix well to prepare a 0.05M acetic acid solution.

[0038] 1.2 Preparation of slurry

[0039] Weigh 0.5g of collagen, first add 2ml of 0.05M acetic acid solution, put it in a grinder to fully grind and crush; then add 8ml of 0.05M acetic acid solution to prepare a 5% collagen slurry. Add the prepared collagen slurry to a 20ml syringe, then connect another empty syringe and pull repeatedly until the collagen is completely dissolved.

[0040] 2...

Embodiment 2

[0057] Taking a model with a collagen slurry concentration of 5%, a repair tube having a diameter of 14mm, a length of 55mm, and a channel diameter of 1.2mm, containing 16 parallel microtubule channels as an example, the manufacturing method includes the following steps:

[0058] 1. Preparation of slurry

[0059] 1.10.05M acetic acid solution preparation

[0060] Take 2-6ml of glacial acetic acid into a 1000ml conical flask, add sterile water to make the volume to 1000ml, and mix well to prepare a 0.05M acetic acid solution.

[0061] 1.2 Preparation of slurry

[0062] Weigh 0.5g of collagen, first add 2ml of 0.05M acetic acid solution, put it in a grinder to fully grind and crush; then add 8ml of 0.05M acetic acid solution to prepare a 5% collagen slurry. Add the prepared collagen slurry to a 20ml syringe, then connect another empty syringe and pull repeatedly until the collagen is completely dissolved.

[0063] 2. Centrifugal

[0064] Centrifuge the prepared slurry at 4000rpm for 60min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com