Methanol thermosynthesis method for preparing stable spherical tetragonal phase rare-earth yttrium zirconium oxide

A technology of yttrium-stabilized zirconia and tetragonal phase, applied in zirconia and other directions, can solve the problems of high energy consumption, complex preparation and production process, product morphology, particle size control, etc., to achieve narrow particle size distribution, good dispersion, suitable for The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

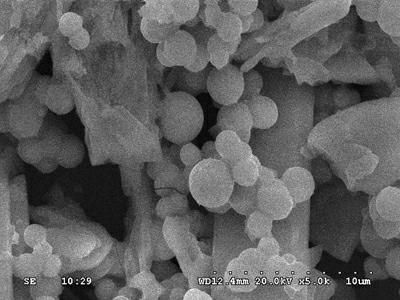

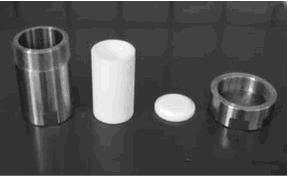

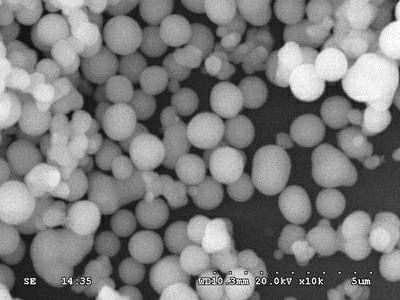

[0033] Example 1: Using ZrOCl 2 ·8H 2 O and YCl 3 ·6H 2 O is the raw material, accurately weigh the corresponding raw materials according to the molar ratio of 97:3, dissolve them in methanol, and transfer to the attached figure 2 Sealed in the PTFE liner shown. Each 10ml volume of the liner is weighed according to 1 gram of the total reactants; the sealed polytetrafluoroethylene liner is placed in a stainless steel jacket, tightened and placed in an oven, heated to 180°C, and kept for 12 hours. Naturally cool to room temperature, take out the inner container, suction filter the reactants, wash with methanol three times, collect the product, and dry it at 60°C for 2 hours. The scanning electron microscopy, XRD, and thermogravimetric images of the obtained product are shown respectively Attached image 3 , 4 , 5, 6. At the same time, part of the product is calcined to 1100°C and kept for 2 hours. The XRD pattern of the obtained product and its comparison with the standard patte...

Embodiment 2

[0034] Example 2: Using ZrOCl 2 ·8H 2 O and YCl 3 ·6H 2 O is the raw material, accurately weigh the corresponding raw materials according to the molar ratio of 97:3, dissolve them in a mixed solvent of methanol and water (the volume ratio of methanol to water is 5:5), dissolve quickly and transfer to the PTFE Seal in the gallbladder. Each 10ml volume of the liner is weighed according to 1 gram of the total reactants; the sealed polytetrafluoroethylene liner is placed in a stainless steel jacket, tightened and placed in an oven, heated to 180°C, and kept for 12 hours. Take out the inner tank, filter the reactants with suction, wash with methanol three times, collect the product, and dry it at 60°C for 2 hours. The scanning electron micrograph and XRD pattern of the obtained product are shown in the attachment. Figure 8 , 10 . It shows that the desired spherical tetragonal phase product cannot be obtained in a reaction system with a large water content. At the same time, part o...

Embodiment 3

[0035] Example 3: Using ZrOCl 2 . 8H 2 O and YCl 3 . 6H 2 O is the raw material, and the corresponding raw materials are accurately weighed according to the molar ratio of 97:3, trying to co-dissolve in ethanol, but it is found that ZrOCl is 2 . 8H 2 O cannot dissolve. Because ZrOCl 2 . 8H 2 O can only dissolve methanol in alcohols. Therefore, other alcohols are not suitable as reaction solvents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com