Transparent ZnO quantum dot/organic silicon nanocomposite material, and preparation method and application thereof

A nanocomposite material and quantum dot technology, which is applied in the field of transparent ZnO quantum dot/organic silicon nanocomposite material and its preparation, can solve the problems of reduced reliability of composite materials, increased surface defects of QDs, and easy migration of quantum dots. , to avoid fluorescence quenching, prevent thermal catalytic degradation, and improve visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

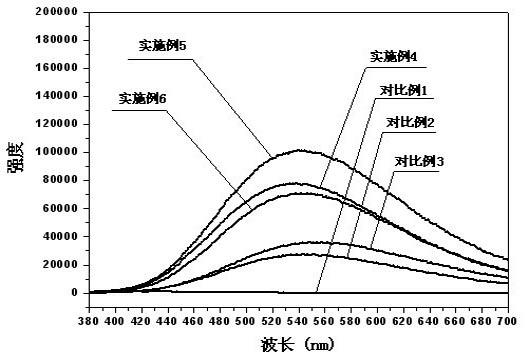

Examples

Embodiment 1

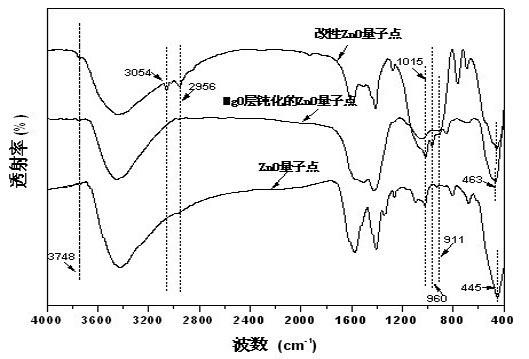

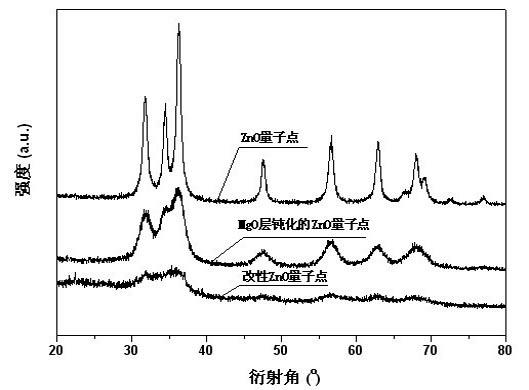

[0029] 1. Preparation of modified ZnO quantum dots

[0030] 1) At 0°C, 50 mL of 0.092 mol / L Zn(CH 3 COO) 2 Mix the ethanol solution of NaOH with 20 mL of 0.5 mol / L NaOH ethanol solution, and stir at 0° C. for 30 min to obtain an ethanol solution containing ZnO quantum dots.

[0031] 2) At 0°C, 10 mL of Mg(CH 3 COO) 2 Slowly add the ethanol solution of the above step 1) into the ethanol solution containing ZnO quantum dots within 30 minutes to obtain the ethanol solution of ZnO quantum dots passivated by the MgO layer.

[0032] 3) At 60°C, mix 0.0057g of vinyltriethoxysilane and 0.0072g of deionized water, add to the ethanol solution of ZnO quantum dots passivated by the MgO layer obtained in the above step 2) and mechanically stir 5h. Then add 80 mL of n-hexane to precipitate the quantum dots, centrifuge, wash with ethanol, and repeat three times to obtain modified ZnO quantum dots.

[0033] 2. Preparation of transparent ZnO quantum dots / organosilicon nanocomposites

...

Embodiment 2

[0036] 1. Preparation of modified ZnO quantum dots

[0037] 1) At 0°C, 17.4mL of 0.12mol / L Zn(CH 3 COO) 2 Mix the ethanol solution of 10 mL of NaOH with a substance concentration of 0.5 mol / L, and stir at 3° C. for 40 min to obtain an ethanol solution containing ZnO quantum dots.

[0038] 2) At 3°C, 12.6mL of 0.033mol / L Mg(CH 3 COO) 2 The ethanol solution of the above step 1) is slowly added dropwise to the ethanol solution containing ZnO quantum dots within 2 hours to obtain the ethanol solution of ZnO quantum dots passivated by the MgO layer.

[0039] 3) At 25°C, mix 0.19g of vinyltrimethoxysilane and 0.021g of deionized water, add to the ethanol solution of ZnO quantum dots passivated by the MgO layer obtained in the above step 2) and mechanically stir for 1h . Then add 20 mL of n-hexane to precipitate the quantum dots, centrifuge and wash with ethanol, repeat three times to obtain modified ZnO quantum dots.

[0040] 2. Preparation of a transparent ZnO quantum dot / org...

Embodiment 3

[0043] 1. Preparation of modified ZnO quantum dots

[0044] 1) At 0°C, mix 130mL of an ethanol solution containing Zn(CH3COO)2 with a concentration of 0.105mol / L and 50mL of an ethanol solution of NaOH with a concentration of 0.5mol / L, and stir at 5°C for 1h , to obtain an ethanol solution containing ZnO quantum dots.

[0045] 2) Under the condition of 5℃, 20mL of 0.033mol / L Mg(CH 3 COO) 2 Slowly add the ethanol solution of the above-mentioned step 1) into the ethanol solution containing ZnO quantum dots within 1 hour, and obtain the ethanol solution of ZnO quantum dots passivated by the MgO layer.

[0046] 3) At 70°C, mix the coupling agent (1.24g 3-methacryloxypropyltrimethoxysilane, 0.95g vinyltrimethoxysilane) and 0.18g deionized water, add to the above step 2) Put the obtained MgO layer passivated ZnO quantum dots in an ethanol solution and mechanically stir for 24 hours. Then add 400mL of n-hexane to precipitate the quantum dots, centrifuge and wash with ethanol thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com