Surface treatment method for improving bioactivity of medical beta-type titanium alloy surface

A technology of biological activity and surface treatment, applied in surface reaction electrolytic coating, medical science, electrolytic coating, etc., can solve problems such as no systematic research, achieve the effect of simple method, improve biological activity, and improve anti-wear ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] After the Ti-24Nb-4Zr-8Sn sample with a diameter of 10 mm and a thickness of 1 mm was polished step by step with 800# and 1200# SiC sandpaper on a pre-grinder, it was ultrasonically cleaned with acetone, absolute ethanol and deionized water for ten minutes each , blow dry in air.

[0045] The process of the described oxidation treatment method is as follows: the anodic oxidation method, the aqueous electrolyte solution is 1 mol / liter NH 4 NO 3 , 0.15 mol / L NH 4 HF 2 , The pH value of the solution is about 6-7.

[0046] At room temperature, the titanium-niobium-zirconium-tin alloy (Ti-24Nb-4Zr-8Sn) was used as the anode, and the stainless steel container was used as the cathode, and the step-by-step boost method was adopted. The boost rate under different test parameters was 0.5V / s, and the oxidation time was from Start timing after boosting to the set voltage. After oxidation, rinse with deionized water.

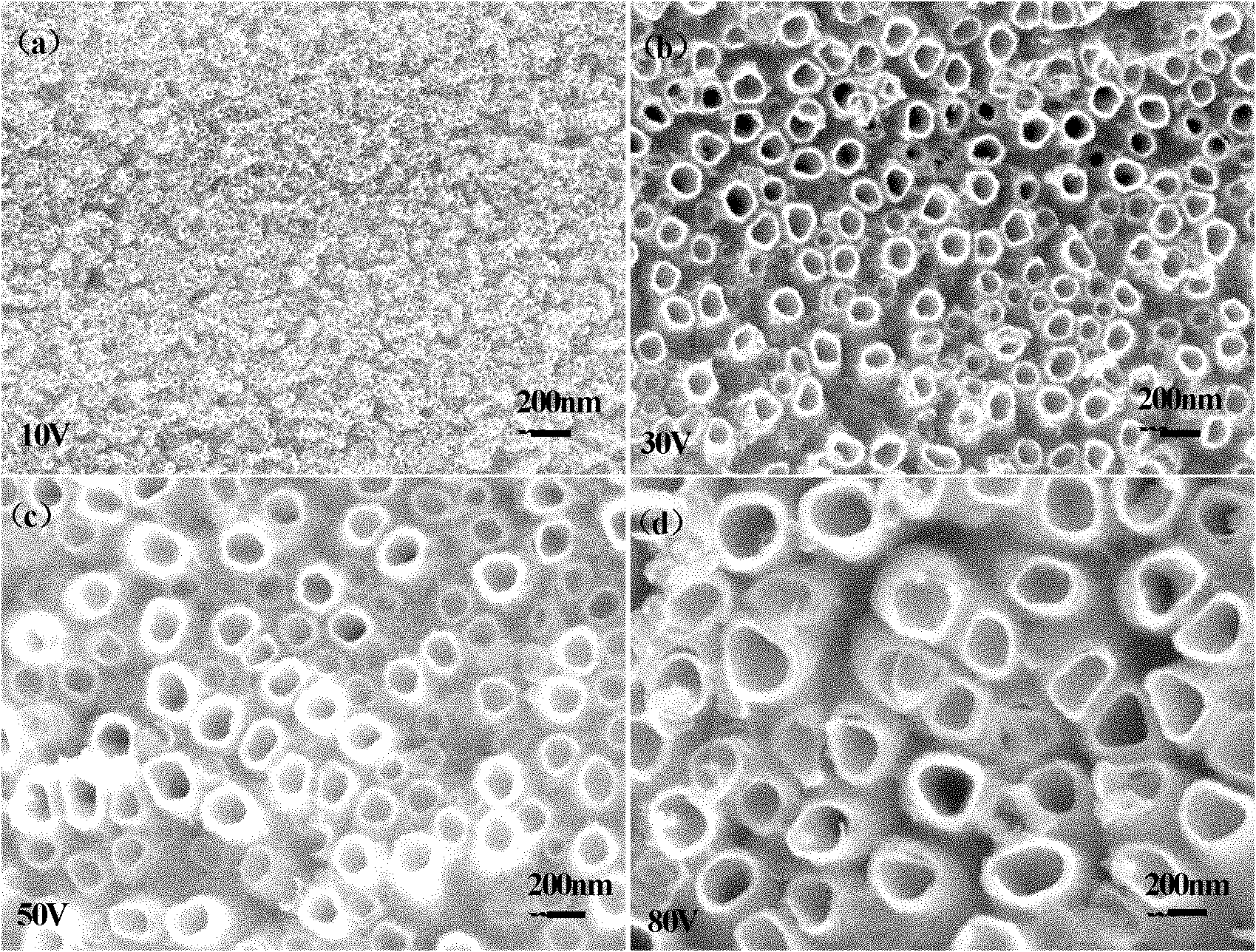

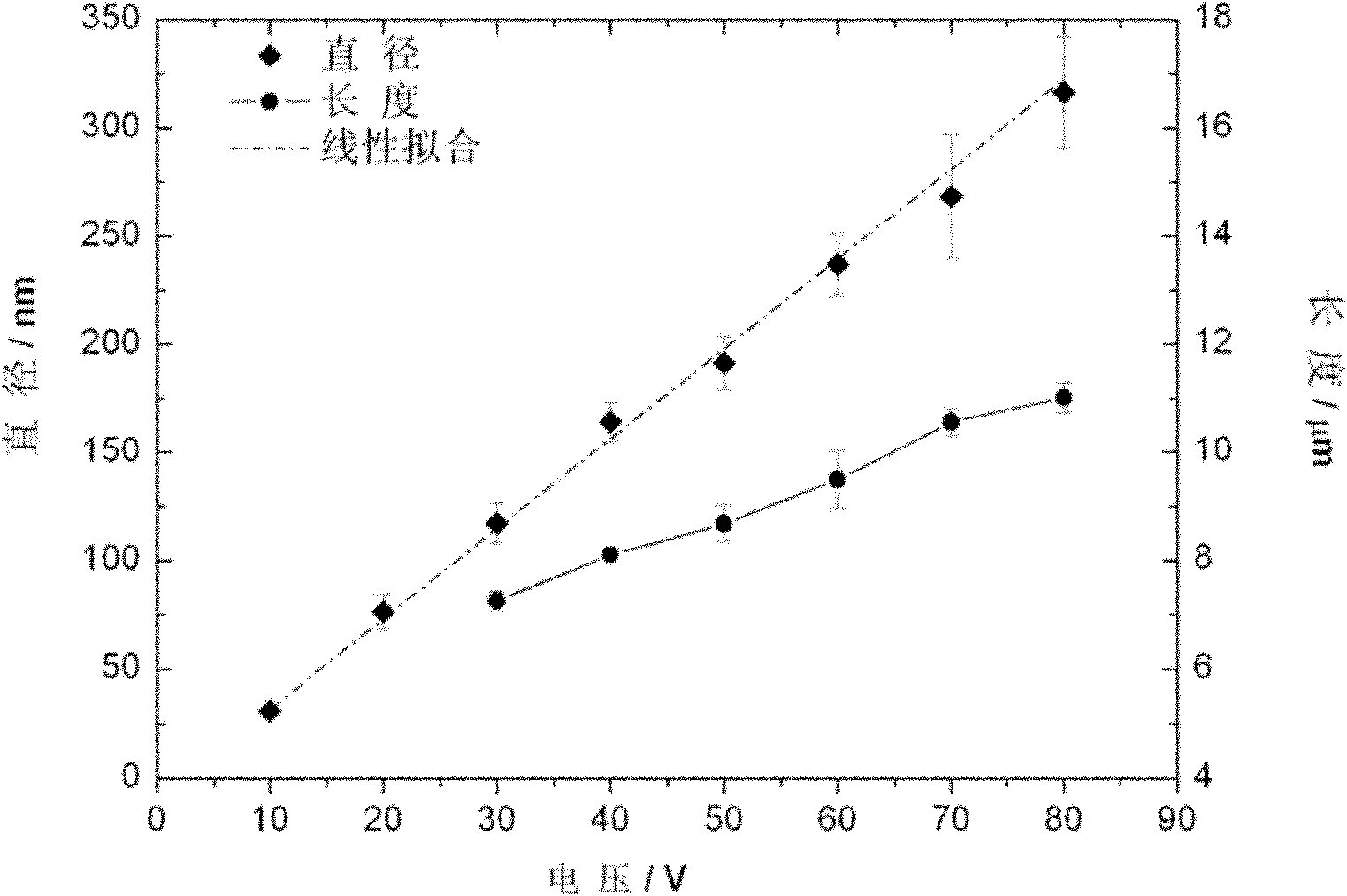

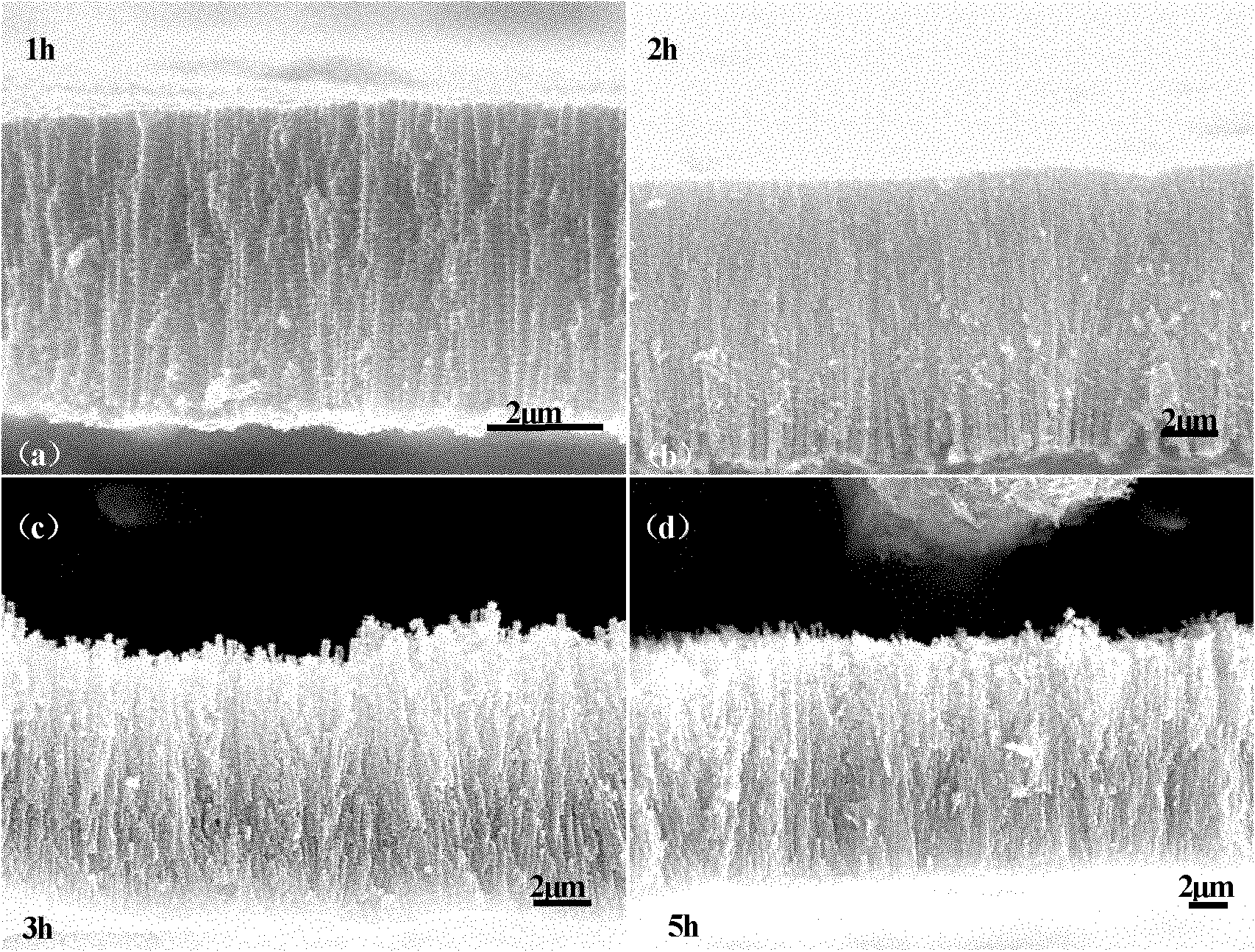

[0047] Set the same oxidation time (1.5h), and the nanotub...

Embodiment 2

[0054] The difference from Example 1 is:

[0055] The Ti-25Nb sample with a diameter of 10 mm and a thickness of 1 mm was ground on a pre-grinder step by step with 800# and 1200# SiC sandpaper, and then ultrasonically cleaned with acetone, absolute ethanol and deionized water for ten minutes each, and blown in the air. Dry.

[0056] The process of the described oxidation treatment method is as follows: the anodic oxidation method, the aqueous electrolyte solution is 1.5 mol / liter NH 4 NO 3 , 0.15 mol / L NH 4 HF 2 , The pH value of the solution is about 6-7.

[0057] At room temperature, titanium-niobium alloy (Ti-25Nb) is used as the anode, and the stainless steel container is used as the cathode. The step-by-step voltage boost method is adopted. The voltage boost speed under different test parameters is 0.5V / s, and the oxidation time is from boost to the set voltage. Then start timing. Rinse with deionized water after oxidation. Setting the same oxidation time (1.5h), t...

Embodiment 3

[0059] The difference from Example 1 is:

[0060] After the Ti-25Zr sample with a diameter of 10mm and a thickness of 1mm was ground step by step on a pre-grinder with 800# and 1200# SiC sandpaper, it was ultrasonically cleaned with acetone, absolute ethanol and deionized water for ten minutes each, and blown in the air. Dry.

[0061] The process of the described oxidation treatment method is as follows: the anodic oxidation method, the aqueous electrolyte solution is 1.5 mol / liter NH 4 NO 3 , 0.15 mol / L NH 4 HF 2 , The pH value of the solution is about 6-7.

[0062] At room temperature, titanium-zirconium alloy (Ti-25Zr) is used as the anode, and the stainless steel container is used as the cathode. The step-by-step boost method is adopted. The boost rate under different test parameters is 0.5V / s, and the oxidation time is from boost to the set voltage. Then start timing. Rinse with deionized water after oxidation. Set the oxidation time (1.5h), and the surface and cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com