Fly ash unburned ceremsite and preparation method as well as application thereof

A technology of fly ash and ceramsite, applied in ceramic products, other household appliances, chemical instruments and methods, etc., can solve the problems of low removal efficiency of heavy metal ions, consumption of heavy metal sludge of large alkaline chemicals, etc., and achieve excellent heavy metal ions. The effect of adsorption performance, convenient operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Raw material pretreatment: After drying the raw material, pass through a 60-mesh sieve;

[0035] 2) Mixing of raw materials: Mix the raw materials evenly according to the following weight ratio: 80 kg of fly ash, 8 kg of cement, and 2 kg of sodium sulfide;

[0036] 2) Granulation: add 20 kg of an aqueous solution of sodium lauryl sulfate with a weight concentration of 0.2% to 100 kg of uniformly mixed raw materials. Granules;

[0037] 3) Curing: Curing the ceramsite blank under natural conditions for 2 hours;

[0038] 4) Steam curing: Steam the cured ceramsite embryos for 6-12 hours under high-temperature steam conditions of 100-180°C;

[0039] The prepared fly ash unfired ceramsite has a good overall shape, well-developed pores and interconnected internal pores. Density 1.35g / cm 3 , bulk density 875kg / m 3 , the strength reaches 5MPa, and the specific surface area is 12m 2 / g.

Embodiment 2

[0041] 1) Raw material pretreatment: After drying the raw material, pass through a 100-mesh sieve;

[0042] 2) Mixing of raw materials: Mix the raw materials evenly according to the following proportions by weight: 40 kg of fly ash, 10 kg of cement, and a mixture of potassium sulfide and calcium sulfide with a weight ratio of 1:1 totals 1 kg;

[0043] 2), granulation: add 30 kg of cetyltrimethylammonium chloride aqueous solution with a weight concentration of 0.5% to 100 kg of uniformly mixed raw materials, the amount of aqueous solution added is 30% of the raw material, stirring and granulating become 10mm ceramsite blank;

[0044] 3) Curing: Curing the ceramsite blank for 4 hours under natural conditions;

[0045] 4) Steam curing: Steam the cured ceramsite embryos for 10 hours under high-temperature steam conditions of 160°C. Example 3

Embodiment 3

[0046] 1) Raw material pretreatment: After drying the raw material, pass it through a 80-mesh sieve;

[0047] 2) Mixing of raw materials: Mix the raw materials evenly according to the following proportions by weight: 60 kg of fly ash, 15 kg of cement, sodium sulfide, potassium sulfide, calcium sulfide, magnesium sulfide, iron sulfide, ferrous sulfide by weight, (the weight ratio of each sulfide is 1:1:1:1:1) a total of 5 kg;

[0048] 2) Granulation: Add 40 kg of an aqueous solution of 0.8% alkylphenol polyoxyethylene ether to 100 kg of uniformly mixed raw materials. The amount of aqueous solution added is 40% of the raw material. Stir and granulate to form a 10mm pottery Granules;

[0049] 3) Curing: Curing the ceramsite blank for 3 hours under natural conditions;

[0050] 4) Steam curing: Steam the cured ceramsite blank for 8 hours under high-temperature steam conditions of 150°C.

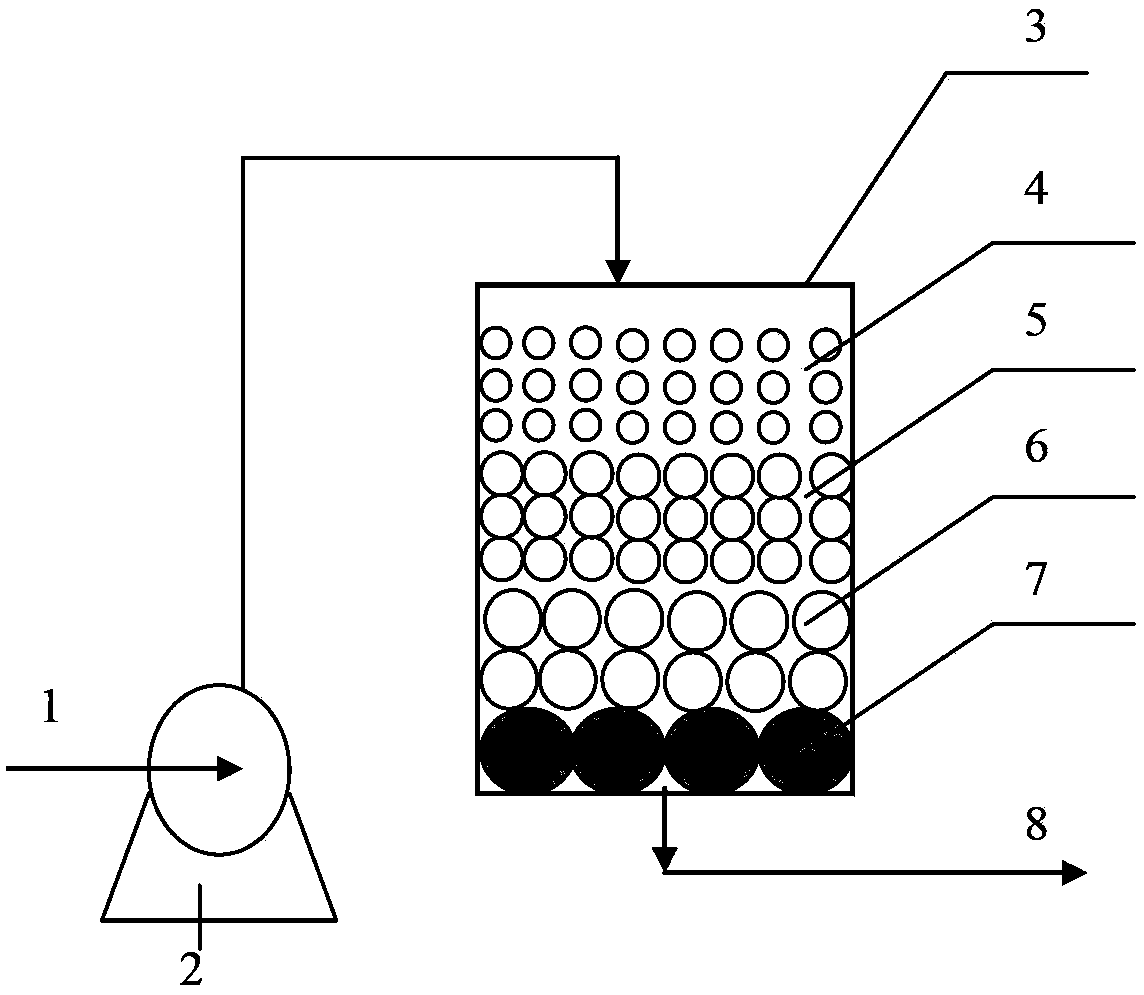

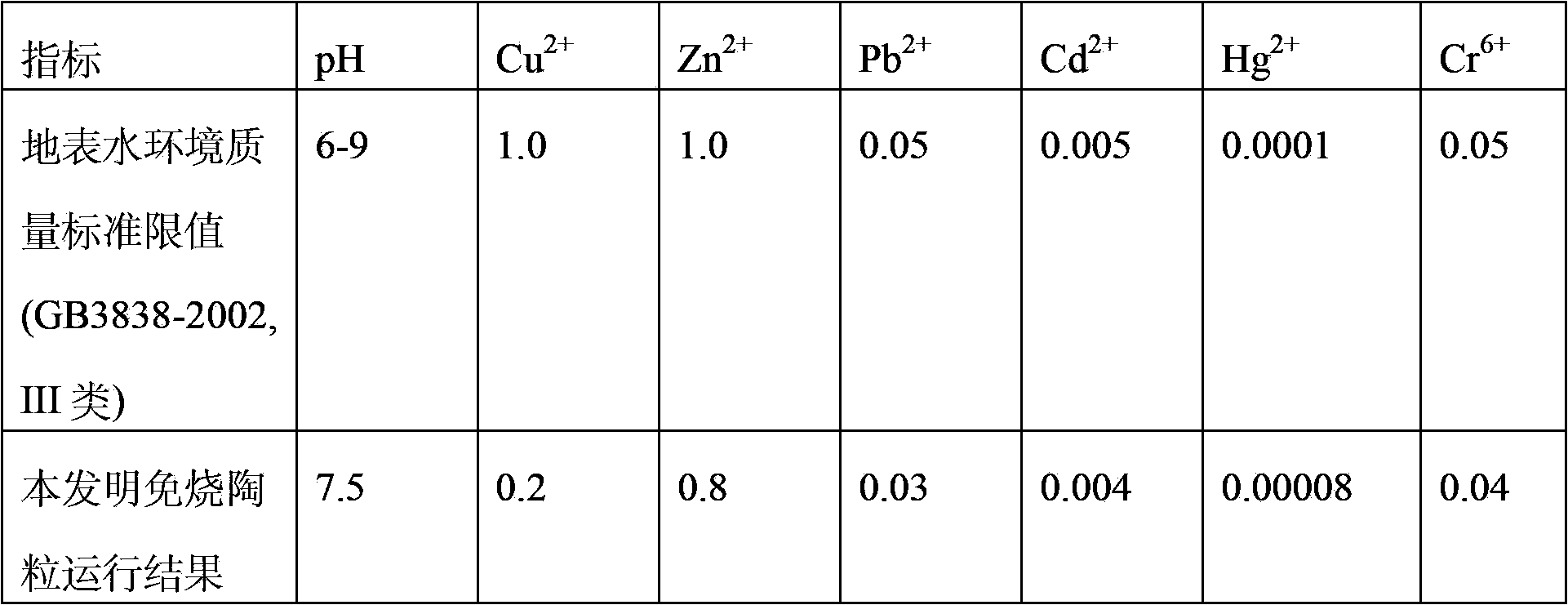

[0051] The use of fly ash unburned ceramsite is mainly used as an adsorption carrier for heav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com