Method for preparing isoflavone aglycone through isoflavone glucoside hydrolysis by malic acid catalysis

A malic acid-catalyzed glycoside type, soybean isoflavone technology, applied in food preparation, organic chemistry, food science, etc., to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

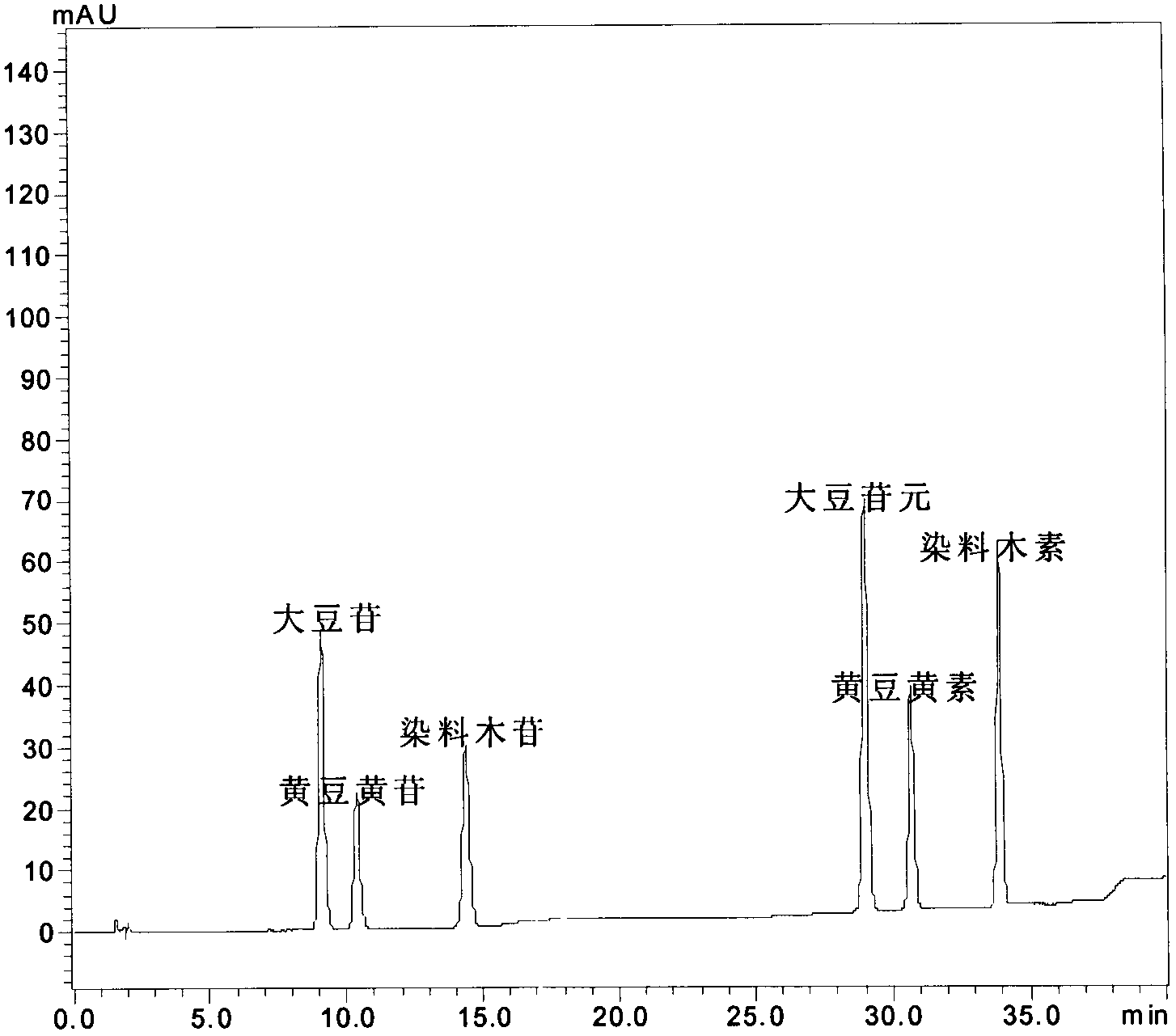

[0022] Take 50mg of 92.0% soybean isoflavone glucoside and place it in a 50mL round bottom flask, add 3.0mol·L -1 Malic acid aqueous solution 10mL, ultrasonic water bath for 1 hour, ultrasonic frequency 45KHz, water bath temperature 75°C. The reaction liquid was transferred to an autoclave, the reaction temperature was 140° C., and the reaction time was 2 hours. After the reaction, the reaction liquid was cooled to room temperature.

[0023] Take a certain amount of the reaction solution and neutralize it to pH=7 with saturated aqueous sodium carbonate solution, extract it with ethyl acetate, take the ester layer, apply it on a silica gel plate, put it into a developing solvent (ethyl acetate:chloroform:methanol=5:5 : 2), observe the degree of hydrolysis under ultraviolet light; another certain amount of reaction solution is diluted to 100ppm with methanol, and the glycoside and aglycon content of the reaction solution are qualitatively and quantitatively detected by HPLC, the...

Embodiment 2

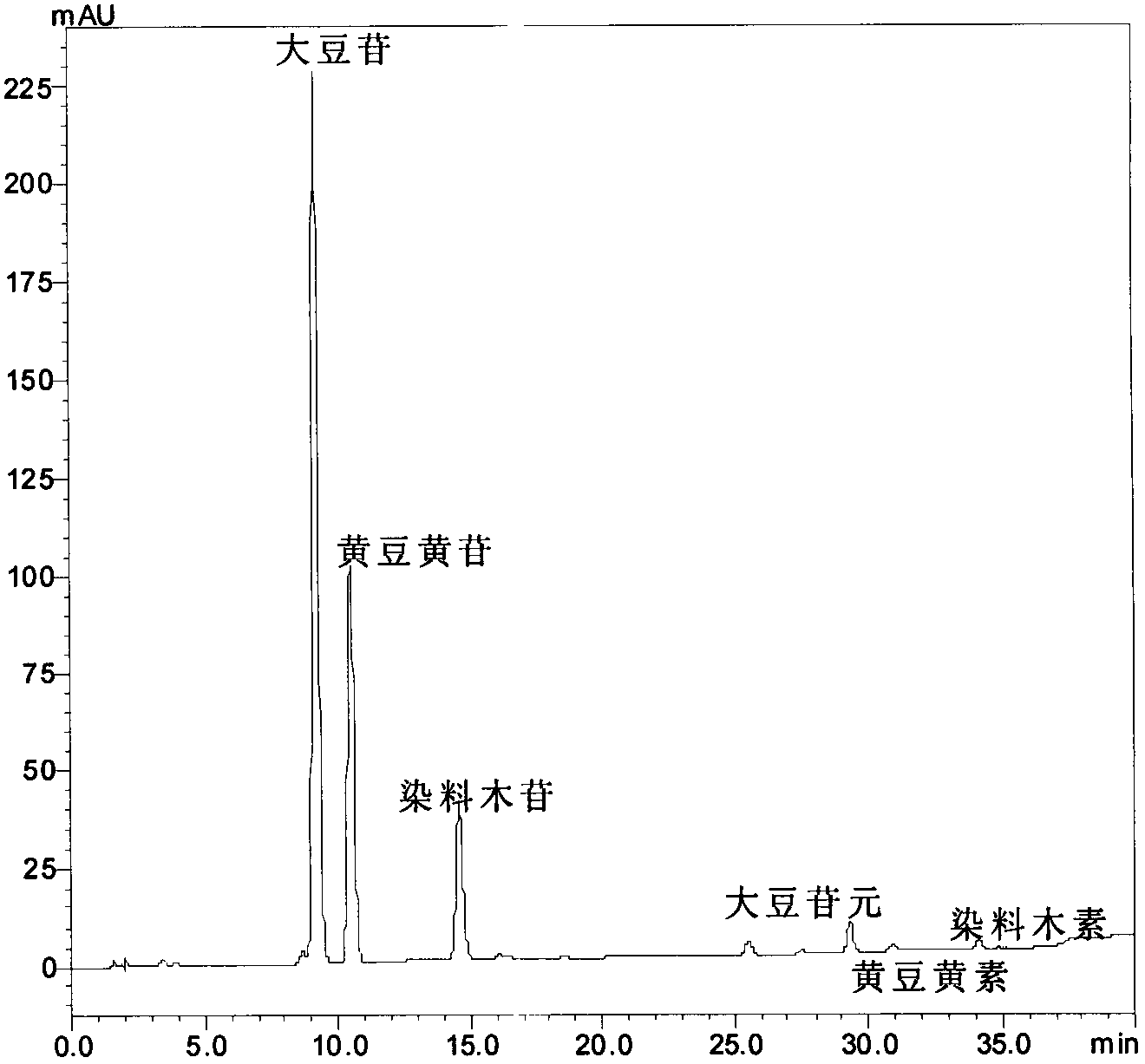

[0025] Take 50mg of 92.0% soybean isoflavone glucoside and put it in a 50mL round bottom flask, add 3.5mol·L -1 Malic acid aqueous solution 10mL, ultrasonic water bath for 1 hour, ultrasonic frequency 45KHz, water bath temperature 75°C. The reaction liquid was transferred to an autoclave, the reaction temperature was 110° C., and the reaction time was 6 hours. After the reaction, the reaction liquid was cooled.

[0026] Other operations are the same as in Example 1. A certain amount of reaction solution is neutralized to pH=7 with saturated aqueous sodium carbonate solution, extracted with ethyl acetate, and the ester layer is taken, spotted on a silica gel plate, and put into a developing solvent (ethyl acetate: Chloroform:methanol=5:5:2) and observe the degree of hydrolysis under ultraviolet light. At the same time, another certain amount of reaction solution was diluted to 100ppm with methanol, and the content of glycoside and aglycone in the reaction solution was qualitat...

Embodiment 3

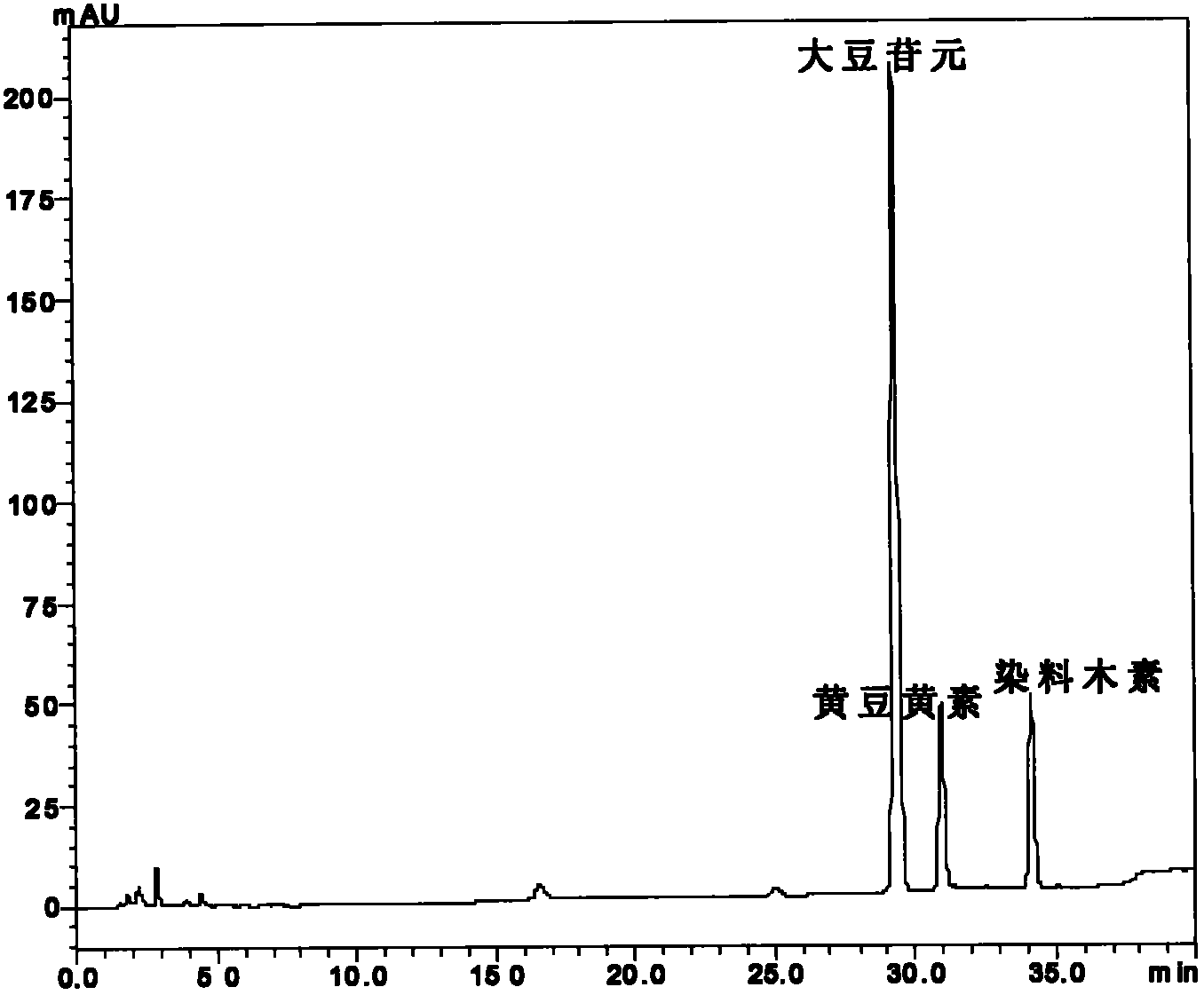

[0028] Take 50mg of 92.0% soybean isoflavone glucoside and put it in a 50mL round bottom flask, add 3.5mol·L -1 Malic acid aqueous solution 10ml, ultrasonic water bath for 1 hour, ultrasonic frequency 45KHz, water bath temperature 75°C. The reaction liquid was transferred to an autoclave, the reaction temperature was 130° C., and the reaction time was 2 hours. After the reaction, the reaction liquid was cooled.

[0029] Other operations are the same as in Example 1. A certain amount of reaction solution is neutralized to pH=7 with saturated aqueous sodium carbonate solution, extracted with ethyl acetate, and the ester layer is taken, spotted on a silica gel plate, and put into a developing solvent (ethyl acetate: Chloroform:methanol=5:5:2) and observe the degree of hydrolysis under ultraviolet light. Simultaneously, another certain amount of reaction solution was diluted to 100ppm with methanol, and the content of glycoside and aglycone in the reaction solution was qualitativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com