Ultra-multiple-pore hydrogel for microbial fermentation and preparation method and application thereof

A technology of porous hydrogel and microbial fermentation, applied in the field of microbial fermentation of ultra-porous hydrogel and its preparation, can solve the problems of environmental hazards, cumbersome steps, limited large-scale production, etc., achieves less pollution, convenient operation, and has The effect of generality and universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

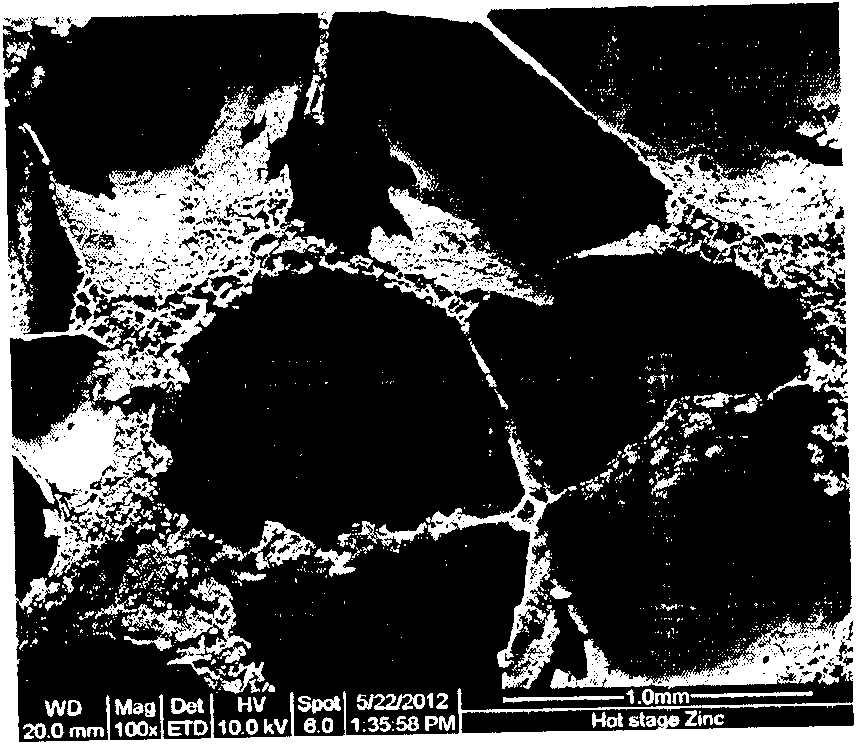

Image

Examples

Embodiment 1

[0031] 1) Preparation of gel pre-polymerization solution: Add 2.0g of acrylamide and 0.1g of N,N'-methylenebisacrylamide to 10mL of deionized water in turn, stir for 20min until all of them are dissolved, and then the gel pre-polymerization solution is obtained ;

[0032] 2) Rehydration and activation of yeast: Dissolve 0.8g of Angel high-activity dry yeast in 10mL of deionized water at 30°C, seal with plastic wrap, stir for 20 minutes, add 0.4g of sugar and continue stirring for 5 minutes to obtain an active yeast solution;

[0033] 3) Preparation of superporous gel: Add the active yeast solution to the gel prepolymerization solution at 30°C, stir for 20 minutes under sealed conditions, add 0.01 g of ammonium persulfate and 160 μL of tetramethylethylenediamine in sequence, and after 5 minutes Slowly pour the mixed solution into a watch glass with an inner diameter of 6cm, and react for 6h;

[0034] 4) Purification of superporous gel: Cut the reacted product into discs with a...

Embodiment 2

[0037] 1) Preparation of gel prepolymerization solution: add 1.0g of isopropylacrylamide and 0.1g of N,N'-methylenebisacrylamide into 10mL of deionized water in turn, stir for 15min until all are dissolved, and the gel is obtained Pre-polymerization liquid;

[0038] 2) Rehydration and activation of yeast: Dissolve 1.0g of Angel high-activity dry yeast in 5mL of deionized water at 26°C, seal with plastic wrap, stir for 25 minutes, add 0.4g of glucose and continue stirring for 10 minutes to obtain an active yeast solution;

[0039] 3) Preparation of superporous gel: Add the active yeast solution to the gel pre-polymerization solution at 26°C, stir for 15 minutes under sealed conditions, add 0.1g potassium persulfate and 80 μL tetramethylethylenediamine in sequence, and after 5 minutes Slowly pour the mixed solution into a watch glass with an inner diameter of 4cm, and react for 4h;

[0040] 4) Purification of superporous gel: cut the reacted product into discs with a diameter o...

Embodiment 3

[0043] 1) Preparation of gel prepolymerization solution: add 1.5g of 2-(dimethylamino)ethyl-methacrylamide and 0.15g of ethylene glycol di(meth)acrylate into 10mL of deionized water in turn, stir for 20min, until Dissolved completely, the gel pre-polymerization solution is obtained;

[0044] 2) Rehydration and activation of yeast: Dissolve 1.2g Champagne yeast in 12mL deionized water at 28°C, seal with plastic wrap, stir for 30min, add 0.6g carboxymethyl chitosan and continue stirring for 20min to obtain active yeast solution;

[0045] 3) Preparation of superporous gel: Add the active yeast solution to the gel pre-polymerization solution at 28°C, stir for 20 minutes under sealed conditions, add 0.05 g of potassium persulfate and 100 μL of tetramethylpropylenediamine in sequence, and after 5 minutes Slowly pour the mixed solution into a watch glass with an inner diameter of 8cm, and react for 4h;

[0046] 4) Purification of superporous gel: Cut the reacted product into discs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com