Phosphorescent luminescent materials and preparation method and application thereof

A technology for luminescent materials and organic material layers, applied in the directions of luminescent materials, organic chemistry, chemical instruments and methods, etc., to achieve the effects of improving luminous efficiency, improving experimental conditions, and simplifying synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

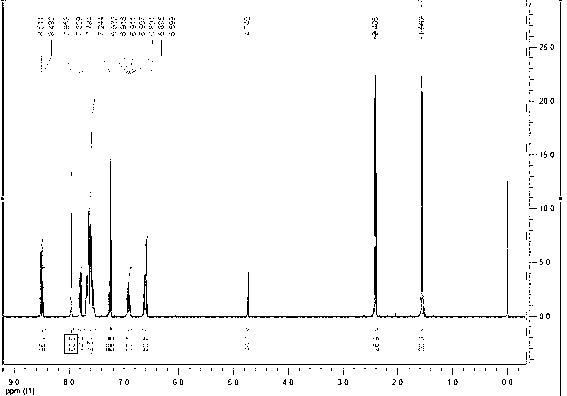

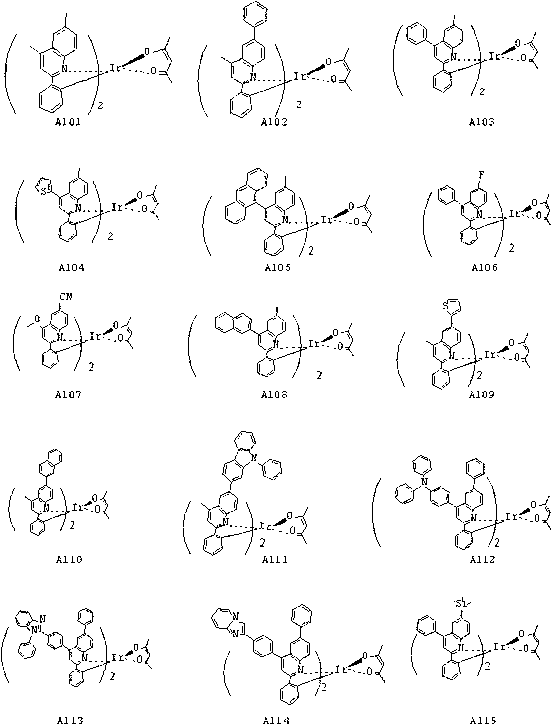

[0024] Synthesis of Example 1 Compound A101

[0025] Step 1, the synthesis of bridging ligand:

[0026]

[0027] Under the nitrogen protection system, weigh 22mmol (5.13g) of the ligand and put 10mmol (3.52g) of IrCl3 3H2O into the reaction system, add a mixed solution of 300ml ethylene glycol ether and 100ml pure water, and reflux for 24 hours under the protection of nitrogen , and then cooled to room temperature, there is a precipitate, the precipitate is suction filtered, rinsed with water, dried, and dichloromethane is used as a detergent, and silica gel column chromatography is used to concentrate and precipitate a solid to obtain 4.2 g of the bridged ligand. The yield is in 92%.

[0028] Step 2, the synthesis of metal iridium complex (A101):

[0029]

[0030] Weigh 4 mmol (3.67 g) of the bridging ligand, add 4.5 g of anhydrous sodium carbonate, add 200 ml of ethylene glycol ether to the system, add 16 mmol (1.6 g) of acetylacetone, reflux for 10 hours u...

Embodiment 2

[0032] Synthesis of Example 2 Compound A103

[0033] Step 1, the synthesis of bridging ligand:

[0034]

[0035] Under nitrogen protection system, weigh 22mmol (6.49g) of the ligand, put IrCl3 3H2O 10mmol (3.52g) into the reaction system, add 300ml ethylene glycol ether and 100ml pure water mixed solution, and reflux for 24 hours under nitrogen protection , and then cooled to room temperature, a precipitate precipitated, the precipitate was suction filtered, rinsed with water, and dried. Dichloromethane was used as a detergent, and silica gel column chromatography was used to concentrate and precipitate a solid to obtain 4.69 g of a bridged ligand. Yield at 90%.

[0036] Step 2, the synthesis of metal iridium complex (A103):

[0037]

[0038] Weigh 4mmol (4.17g) of the bridging ligand, add 4.5g of anhydrous sodium carbonate, add 200ml of ethylene glycol ether to the system, add 16mmol (1.6g) of acetylacetone, reflux for 15 hours under nitrogen protection, and...

Embodiment 3

[0040] Example 3 Synthesis of Compound A109

[0041] Step 1, the synthesis of bridging ligand:

[0042]

[0043] Under nitrogen protection system, weigh 22mmol (6.62g) of the ligand, put IrCl3 3H2O 10mmol (3.52g) into the reaction system, add 300ml ethylene glycol ether and 100ml pure water mixed solution, and reflux for 24 hours under nitrogen protection , and then cooled to room temperature, a precipitate precipitated, the precipitate was suction filtered, rinsed with water, and dried. Using dichloromethane as a detergent, silica gel column chromatography was used to concentrate and precipitate a solid to obtain 4.91 g of a bridged ligand. Yield at 93%.

[0044] Step 2, the synthesis of metal iridium complex (A109):

[0045]

[0046] Weigh 4 mmol (4.22 g) of the bridging ligand, add 4.5 g of anhydrous sodium carbonate, add 200 ml of ethylene glycol ether to the system, add 16 mmol (1.6 g) of acetylacetone, reflux for 12 hours under nitrogen protection, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com