Method for natural gas desulphurization and resource utilization of desulphurization waste solution

A technology for desulfurization waste liquid and natural gas, applied in chemical instruments and methods, alkali metal sulfide/polysulfide, gaseous discharge wastewater treatment, etc., can solve problems such as environmental pollution, achieve significant environmental benefits, high added value, Significant economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

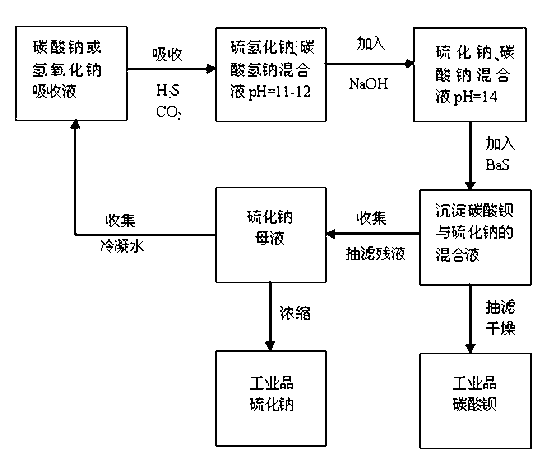

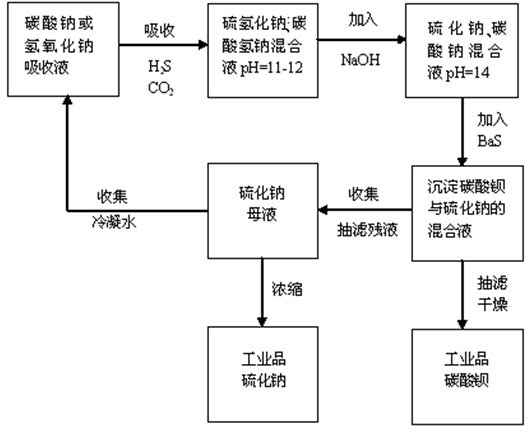

Method used

Image

Examples

Embodiment 1

[0040] 1. Prepare sodium hydroxide absorption solution, the volume is 1 liter; the mass percentage concentration is 5%;

[0041] 2. Prepare sodium hydroxide solution, the volume is 1 liter; the mass percentage concentration is 10%;

[0042] 3. Prepare barium sulfide solution, the volume is 1 liter; the mass percentage concentration is 15%;

[0043] 4. Mix 1 liter of sodium hydroxide absorption solution with H 2 The content of S is 1%, CO 2The content is 1000 liters of natural gas of 4.5% to carry out gas-liquid reaction, when the pH=12 of recording absorption liquid, stop reaction; Add above-mentioned 10% concentration sodium hydroxide solution 0.5 liters in absorption liquid, record the pH=12 of absorption liquid 14; Then when the absorption solution is heated to 80°C, add 1 liter of the above-mentioned 15% barium sulfide solution, and a white precipitate is precipitated in the reaction; carry out solid-liquid separation; wash, suction filter, and dry the white precipitate ...

Embodiment 2

[0045] 1. Prepare sodium carbonate absorption solution, the volume is 2 liters; the mass percentage concentration is 8%;

[0046] 2. Prepare sodium hydroxide solution, the volume is 1 liter; the mass percentage concentration is 10%;

[0047] 3. Prepare a barium sulfide solution with a volume of 3 liters; a mass percentage concentration of 15%;

[0048] 4. Mix 1.6 liters of sodium hydroxide absorption solution with H 2 The content of S is 1%, CO 2 The content is 1000 liters of natural gas of 4.5% to carry out gas-liquid reaction, when the pH=12 of recording absorption liquid, stop reaction; Add above-mentioned 1 liter of sodium hydroxide solution of 10% concentration in absorption liquid, record the pH=12 of absorption liquid 14; Then, when the absorption liquid was heated to 80°C, 2.2 liters of the above-mentioned 15% barium sulfide solution was added, and a white precipitate was precipitated during the reaction; solid-liquid separation was carried out; washing, suction filt...

Embodiment 3

[0050] 1. Prepare sodium hydroxide absorption solution, the volume is 2 liters; the mass percentage concentration is 3%;

[0051] 2. Prepare a sodium hydroxide solution with a volume of 0.5 liters; a mass percentage concentration of 8%;

[0052] 3. Prepare a barium sulfide solution with a volume of 1 liter; a mass percentage concentration of 10%;

[0053] 4. Mix 1.45 liters of sodium hydroxide absorption solution with H 2 The content of S is 1.5%, CO 2 The content is 3% natural gas 1000 liters to carry out gas-liquid reaction, when the pH=11 of recording absorption liquid, stop reaction; Add above-mentioned 8% sodium hydroxide solution 0.5 liters in absorption liquid, record the pH=11 of absorption liquid 14; Then, when the absorption liquid is heated to 75°C, add 1 liter of barium sulfide with a concentration of 10% above to dissolve 1 liter, and a white precipitate is precipitated in the reaction; carry out solid-liquid separation; wash, filter, and dry the white precipita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com