Technology for recovering valuable metals from noble metal slag

A technology of valuable metals and precious metals, applied in the direction of improving process efficiency, etc., can solve problems such as ineffective recovery, long recovery time, and low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

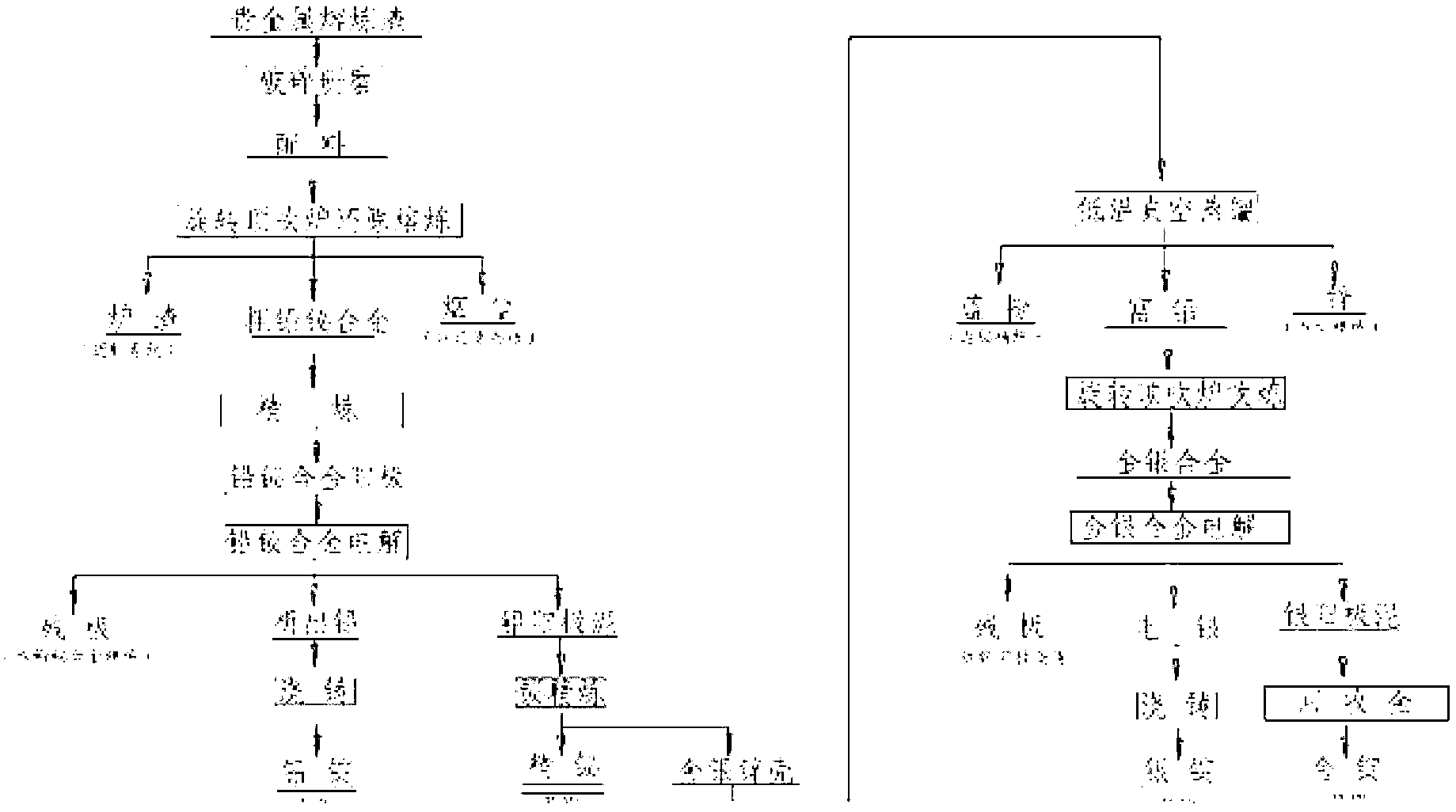

[0059] Such as figure 1 Shown is a flow chart of the process for recovering valuable metals from precious metal smelting slag provided by the present invention.

[0060] The precious metal smelting slag composition of table 1 embodiment 1

[0061] the element

Au

Ag

Bi

Pb

Cu

Sb

As

SiO 2

content

500g / t

1%

6.4%

45%

0.3%

1%

1%

10%

[0062] Production of lead-bismuth alloy from precious metal smelting slag

[0063] The composition of the precious metal smelting slag used in this example is shown in Table 1. The precious metal smelting slag is ground to 100 mesh after two stages of crushing, and the qualified precious metal smelting slag is sent to the top slag bin of the rotary top-blowing furnace by air conveying. . The precious metal smelting slag, quartz, sodium carbonate, quicklime, coke powder, and lead oxide in the top hopper are automatically added to the rotary top-blow...

Embodiment 2

[0110] The precious metal smelting slag composition of table 5 embodiment 2

[0111] the element

Au

Ag

Bi

Pb

Cu

Sb

As

SiO 2

content

100g / t

0.4%

8%

30%

0.3%

1.2%

1.8%

5

[0112] Production of lead-bismuth alloy from precious metal smelting slag

[0113] The precious metal smelting slag is crushed in two stages and then ground to 70 mesh, and the qualified precious metal smelting slag is sent to the top slag bin of the rotary top-blowing furnace by air conveying. The precious metal smelting slag, quartz, sodium carbonate, quicklime, coke powder, and lead oxide in the top hopper are automatically added to the rotary top-blowing furnace through the mechanical feeding system according to the batching ratio. Insert a combustion lance to carry out reduction melting at 850~1100°C. After smelting, the slag is released to produce crude lead-bismuth alloy. The hot crude lead-bismuth a...

Embodiment 3

[0157] The precious metal smelting slag composition of table 8 embodiment 3

[0158] the element

Au

Ag

Bi

Pb

Cu

Sb

As

Na 2 CO 3

content

20g / t

0.2%

3%

10%

0.01%

1.6%

1.5%

5%

[0159] Production of lead-bismuth alloy from precious metal smelting slag

[0160] The precious metal smelting slag is crushed in two stages and then ground to 50 mesh, and the qualified precious metal smelting slag is sent to the top slag bin of the rotary top-blowing furnace by air conveying. The precious metal smelting slag, quartz, sodium carbonate, quicklime, coke powder, and lead oxide in the top hopper are automatically added to the rotary top-blowing furnace through the mechanical feeding system according to the batching ratio. Insert a combustion lance to carry out reduction melting at 850~1100°C. After smelting, the slag is released to produce crude lead-bismuth alloy. The hot crude lead-bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com