Preparation method of ZnTe/GaAs heteroepitaxial layer

A heteroepitaxial, zinc telluride technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems that affect the application, the deviation of the zinc telluride epitaxial layer from the ideal stoichiometry, affect the epitaxy Layer crystal quality and other issues, to achieve the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

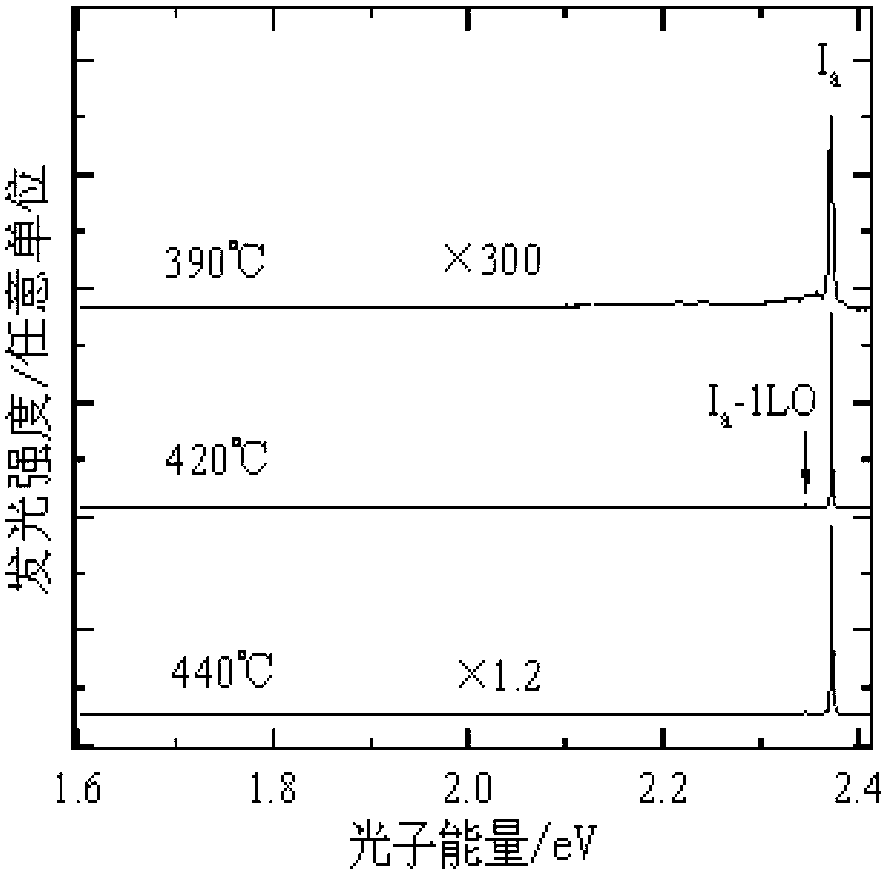

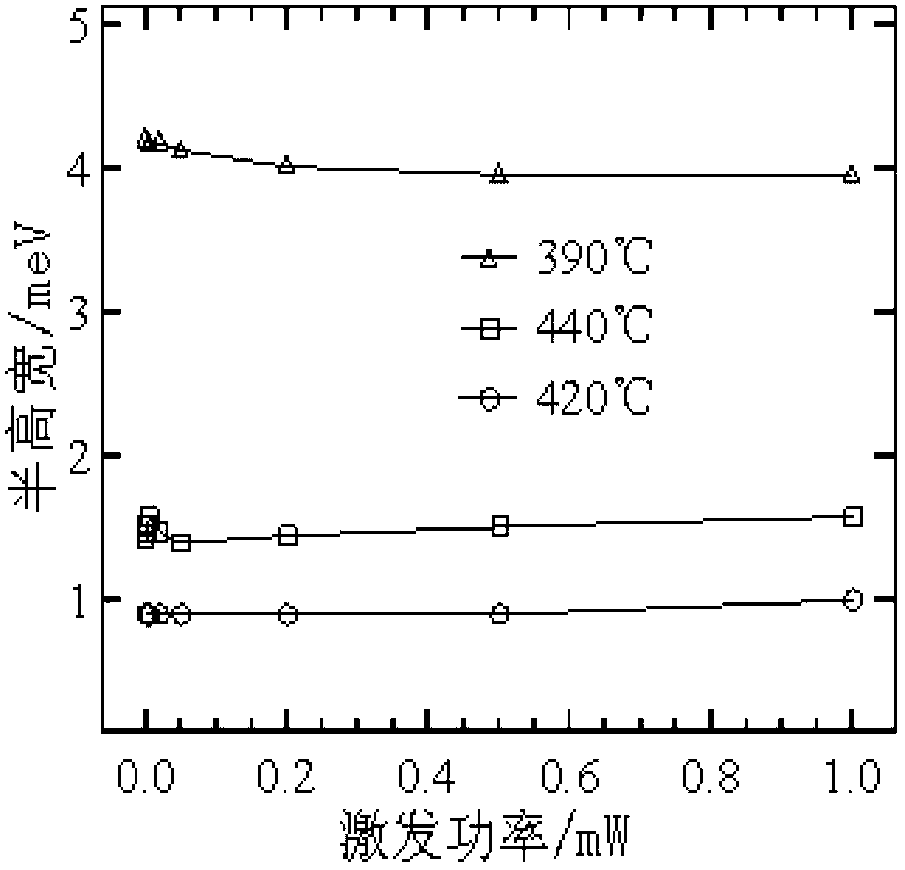

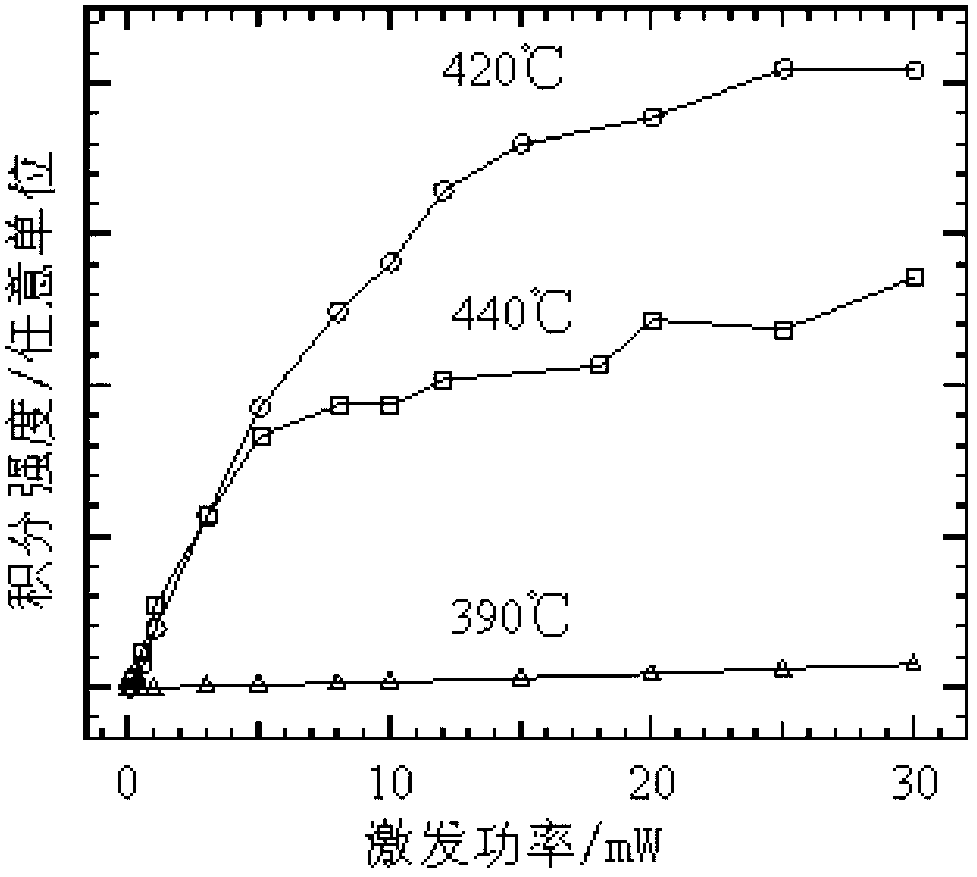

[0043] A method for preparing a zinc telluride / gallium arsenide heteroepitaxial layer, using a metal organic chemical vapor phase epitaxy process, using dimethyl zinc and diethyl tellurium as metal organic sources, using hydrogen as a carrier gas, and using metal organic chemistry Vapor phase epitaxy equipment grows zinc telluride epitaxial layer on gallium arsenide substrate; the process conditions are as follows:

[0044] Reaction chamber background vacuum degree: 1×10 -7 Torr;

[0045] Substrate temperature during growth: 420°C;

[0046] Transport rate of dimethyl zinc: 15μmol / min;

[0047] Transport rate of diethyl tellurium: 15 μmol / min;

[0048] The operation steps of above-mentioned preparation method are as follows:

[0049]1. Cleaning of the GaAs substrate: chemically clean the polished (100) GaAs, ultrasonically clean it in acetone for 5 minutes, and place it in a H 2 SO 4 、H 2 o 2 and H 2 O was etched at 60°C for 20 seconds in a solution composed of a ratio...

Embodiment 2

[0055] The process conditions are as follows:

[0056] Reaction chamber background vacuum degree: 1.2×10 -7 Torr;

[0057] Substrate temperature during growth: 410°C;

[0058] Transport rate of dimethyl zinc: 10 μmol / min;

[0059] Transport rate of diethyl tellurium: 10 μmol / min;

[0060] Growth time: 4 hours;

[0061] ZnTe / GaAs epitaxial layer prepared by MOVPE process, the steps are as follows:

[0062] 1. Cleaning of the GaAs substrate: chemically clean the polished (100) GaAs, ultrasonically clean it in acetone for 5 minutes, and place it in a H 2 SO 4 、H 2 o 2 and H 2 O (according to the ratio of 5:1:1) was etched at 50°C for 20 seconds, and finally rinsed with deionized water;

[0063] 2. Pump the MOVPE equipment reaction chamber into a high vacuum state with a vacuum degree of 1.2×10 -7 Torr, the substrate is heated to 550 ° C for 35 minutes to remove the oxide on the surface of the GaAs substrate;

[0064] 3. Control the substrate temperature at 410°C, adju...

Embodiment 3

[0067] The process conditions are as follows:

[0068] Reaction chamber background vacuum degree: 0.8×10 -7 Torr;

[0069] Substrate temperature during growth: 430°C;

[0070] Transport rate of dimethyl zinc: 30μmol / min;

[0071] Transport rate of diethyl tellurium: 30μmol / min;

[0072] Growth time: 2 hours;

[0073] ZnTe / GaAs epitaxial layer prepared by MOVPE process, the steps are as follows:

[0074] 1. Cleaning of the GaAs substrate: chemically clean the polished (100) GaAs, ultrasonically clean it in acetone for 5 minutes, and place it in a H 2 SO 4 、H 2 o 2 and H 2 O (according to the ratio of 5:1:1) was etched at 70°C for 20 seconds, and finally rinsed with deionized water;

[0075] 2. Pump the MOVPE equipment reaction chamber into a high vacuum state with a vacuum degree of 0.8×10 -7 Torr, the substrate is heated to 600 ° C for 40 minutes to remove the oxide on the surface of the GaAs substrate;

[0076] 3. Control the substrate temperature at 430°C, adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com