ITO (indium tin oxid) nanofiber/cadmium sulfide (CdS) quantum dot solar cell and preparing method thereof

A technology of solar cells and nanofibers, applied in the field of solar cells, can solve problems such as increased cell efficiency, recombination of photogenerated electrons, and influence on cell current, and achieves the effects of improving bonding strength, simple preparation process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

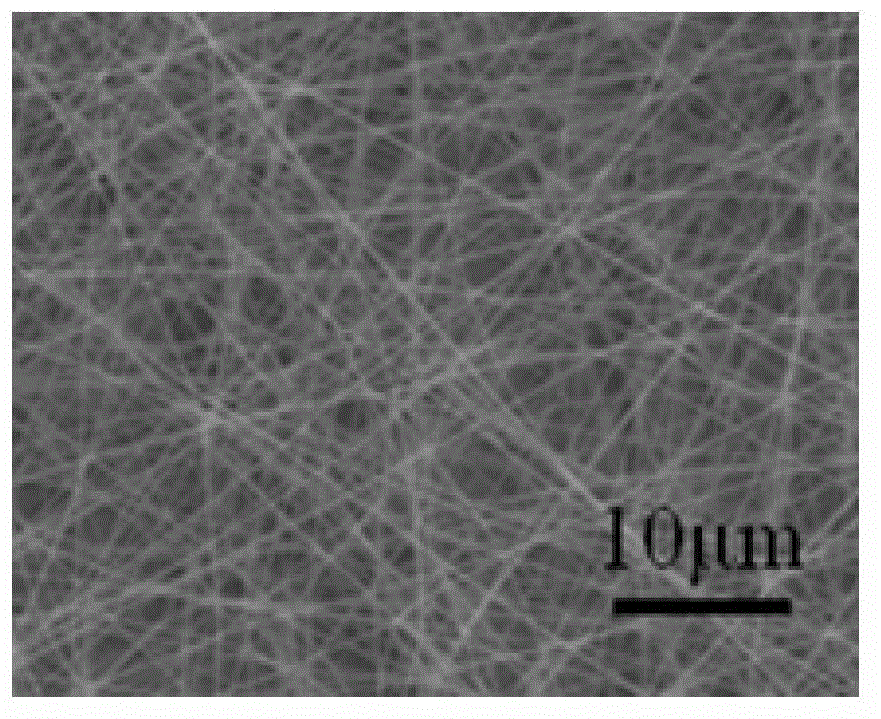

[0027] The FTO glass (fluorine-doped SnO 2 Conductive glass) Prepare a layer of polyvinylpyrrolidone PVP film by suspension coating method; at the same time, configure 10ml of mixed solution of water and dimethylformamide DMF according to the volume ratio of 3:1, and add 0.094g tin chloride, 0.9g indium nitrate, 0.8g of PVP, and 0.1ml of acetic acid was added, heated and stirred at 90°C for 30 minutes to configure the spinning solution. Put the spinning solution in the spinning device, place the FTO glass at the fiber collection position, set the spinning voltage to 15KV, and the spinning distance to 15cm, and spin for 10 minutes to obtain PVP nanofibers. Take out the prepared PVP nanofibers and anneal at 180°C for half an hour, then take out the nanofibers, apply 10% PEG solution evenly on the surface of the fibers, and after cooling to room temperature, anneal at 500°C for half an hour to obtain ITO nanofiber anode. The prepared ITO nanofiber anode was electrochemically de...

Embodiment 2

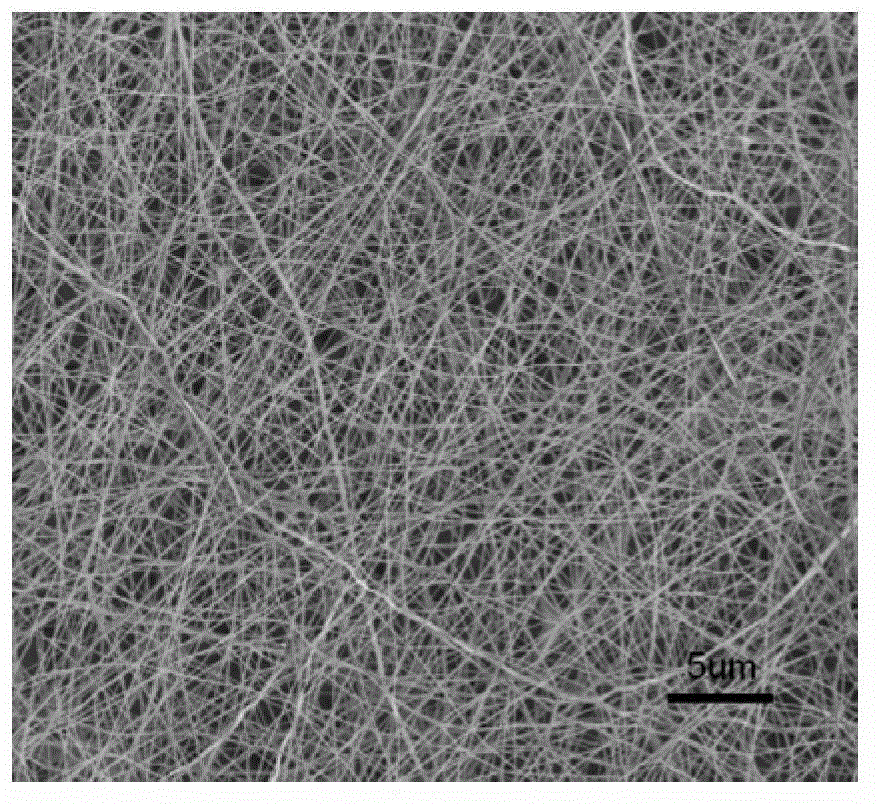

[0029] The FTO glass (fluorine-doped SnO 2 Conductive glass) Prepare a layer of polyvinylpyrrolidone PVP film by suspension coating method; at the same time, configure 10ml of mixed solution of water and dimethylformamide DMF according to the volume ratio of 3:1, and add 0.094g tin chloride, 0.9g indium nitrate, 0.8g of PVP, and 0.1ml of acetic acid was added, heated and stirred at 90°C for 30 minutes to configure the spinning solution. Put the spinning solution in the spinning device, place the FTO glass at the fiber collection position, set the spinning voltage to 15KV, and the spinning distance to 15cm, and spin for 20 minutes to obtain PVP nanofibers. Take out the prepared PVP nanofibers and anneal at 180°C for half an hour, then take out the nanofibers, apply 10% PEG solution evenly on the surface of the fibers, and after cooling to room temperature, anneal at 500°C for half an hour to obtain ITO nanofiber anode. The prepared ITO nanofiber anode was electrochemically de...

Embodiment 3

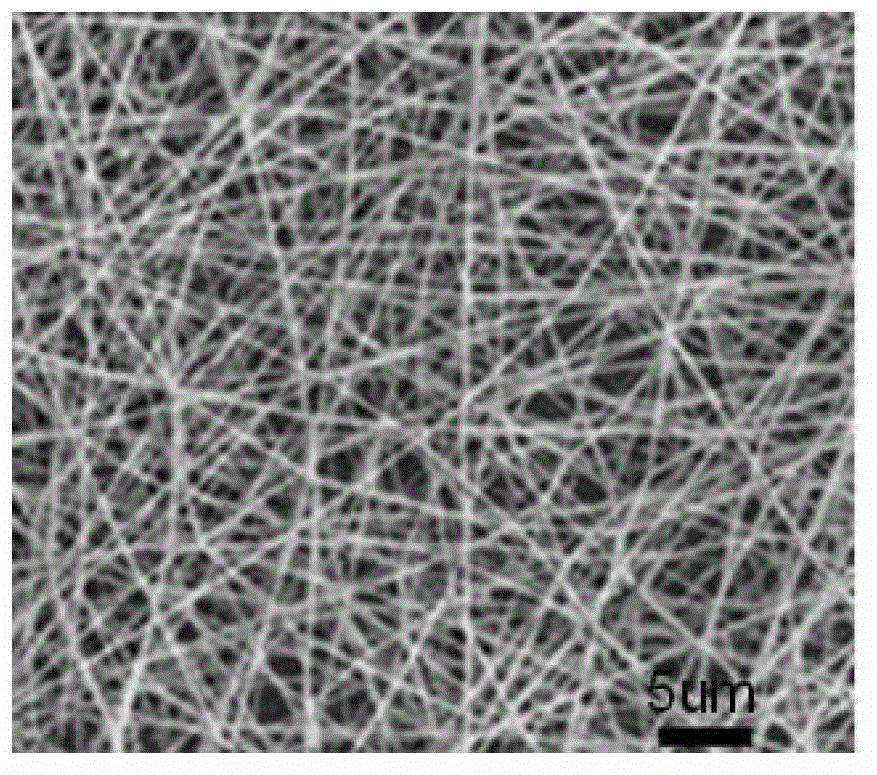

[0031] The FTO glass (fluorine-doped SnO 2 Conductive glass) Prepare a layer of polyvinylpyrrolidone PVP film by suspension coating method; at the same time, configure 10ml of mixed solution of water and dimethylformamide DMF according to the volume ratio of 3:1, and add 0.094g tin chloride, 0.9g indium nitrate, 0.8g of PVP, and 0.1ml of acetic acid was added, heated and stirred at 90°C for 30 minutes to configure the spinning solution. Put the spinning solution in the spinning device, place the FTO glass at the fiber collection position, set the spinning voltage to 15KV, the spinning distance to 15cm, and spin for 30 minutes to obtain PVP nanofibers. Take out the prepared PVP nanofibers and anneal at 180°C for half an hour, then take out the nanofibers, apply 10% PEG solution evenly on the surface of the fibers, and after cooling to room temperature, anneal at 500°C for half an hour to obtain ITO nanofiber anode. The prepared ITO nanofiber anode was electrochemically deposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com